The Liberator12k is a revolving 12 gauge shotgun which uses mostly 3D printed parts combined with easily available metal components including steel tubing for the barrel and chamber inserts. The basic idea behind the design is to allow anyone with a $200 3D printer to be able to simply order some suitable steel tubing along with some standard steel fittings and from then be able to easily assemble a reliable and safe homemade repeating shotgun capable of 6-7 successive shots of widely available 12 gauge. The gun is the creation and current project of Jeff Rodiguez, whose experiments with using ECM (Electrochemical Machining) to create rifling were covered in a previous article back in 2017.

The most recent video Jeff released shows the Liberator12k being test fired. The initial results look very promising and with further improvement could potentially result in a DIY weapon every bit as viable as a commercially produced firearm.

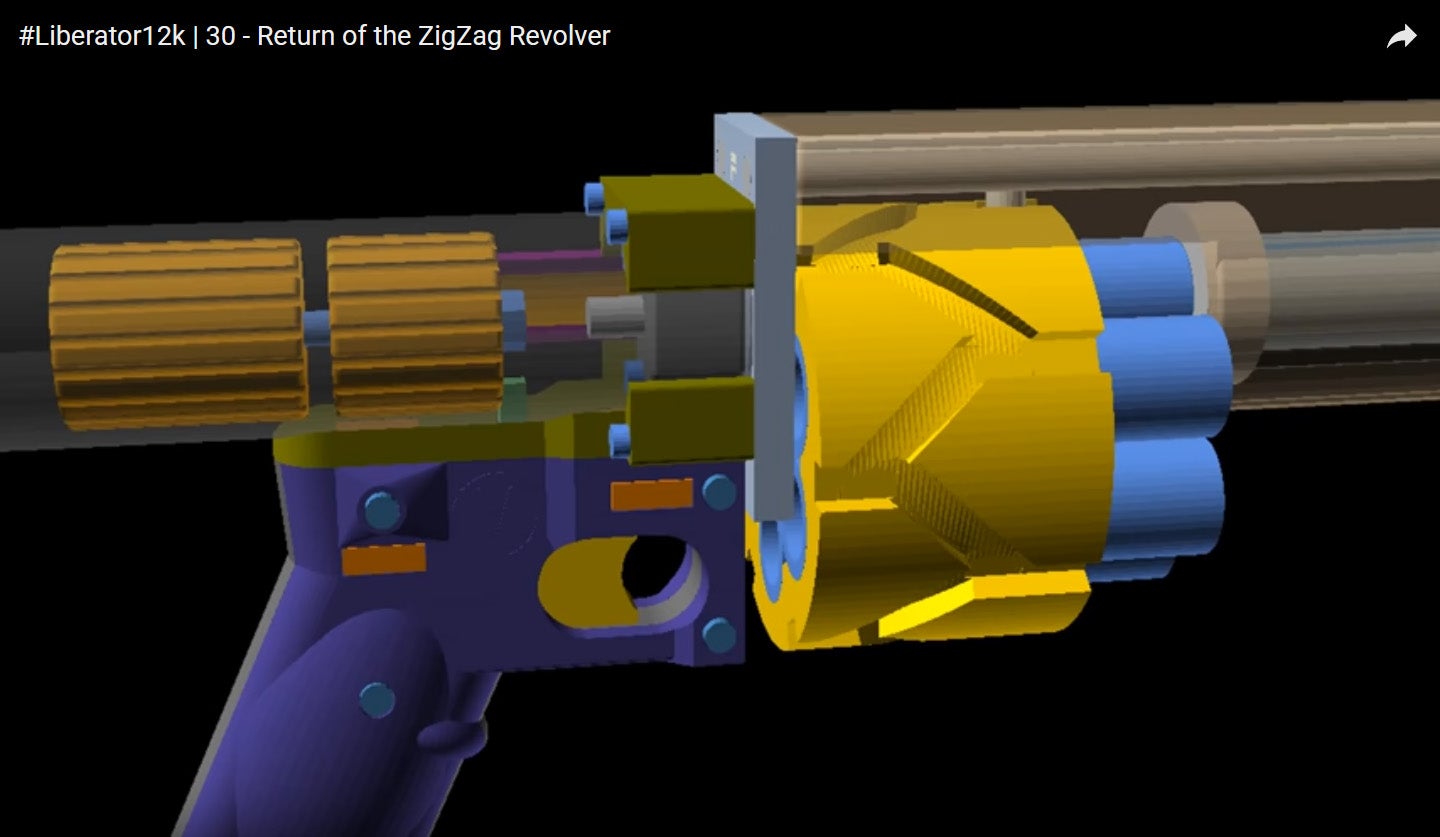

The current Liberator12k prototype model. The shotgun is a combination of 3D printed PLA combined with steel tubing inserts and reinforced with steel studding rods.

The action is relatively straightforward and like several other 3D printed designs released in the past uses a series of zig-zag grooves to translate linear motion. This is essentially the same design the Pancor Jackhammer uses.

Below: Cocked position with sear engaged with striker and ready to fire:

Below: Trigger pulled and striker travels forward to strike the firing pin, firing a shell.

Below: Pump arm moved rearward, re-cocking striker and rotating drum counterclockwise from the user through the interaction of the cocking bar with a series of groove channels.

Construction of the cylinder: An outer printed unit holds six to seven sections of 3/4″ inner diameter thick-walled steel tubing.

Dissembled barrel & frame assembly, striker and trigger unit.

A close up of the striker which is assembled from two printed cylindrical pieces combined with a long bolt, nut, and washer. A spring is inserted between each cylindrical piece.

A view inside the cylindrical receiver tube which houses the striker. The sear piece can be seen protruding which catches the striker.

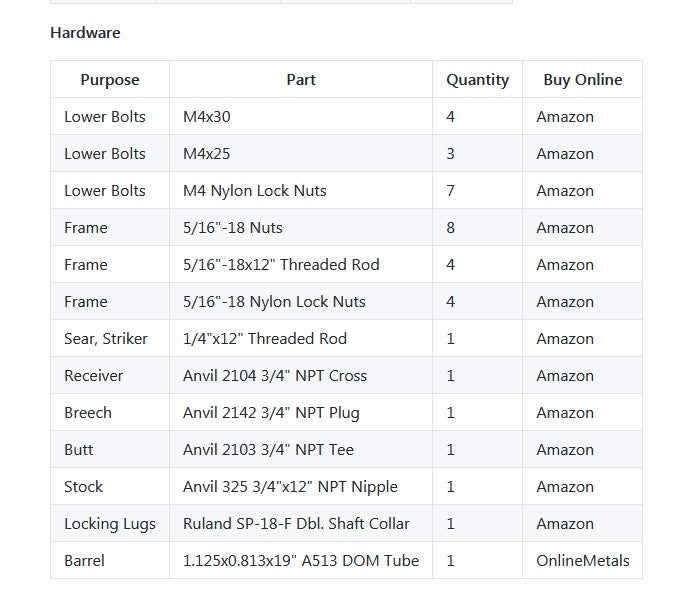

A list of hardware store components used:

Additional material and updates relating to the Liberator12k project can be found here.

Your Privacy Choices

Your Privacy Choices