A couple of months ago I had the chance to field strip a Heckler & Koch G11, the caseless ammunition-firing assault rifle. There are few experimental weapons that have cultivated myth and reputation like Heckler & Koch’s G11 and it was a privilege to take a look inside one.

The culmination of twenty years of research and development, the G11 was Germany’s attempt to combine advanced caseless ammunition with a weapon system which could increase the average infantryman’s hit probability. It was later submitted to the US Army’s Advanced Combat Rife programme in the mid/late 1980s where it went up against designs from Steyr, Colt and AAI. It could fire in single shot, full auto and fire a 3 round burst at a rate of 2,000 rounds per minute – that’s about 33 rounds per second. It had a rotating chamber and used an advanced recoil management system to mitigate the felt recoil.

G11 with its forend and butt stock removed, the control disk and the rotating breech cylinder have been removed too (Matthew Moss)

I was understandably nervous about opening up the G11, it has a legendary reputation for being one of the most complex infantry rifles ever designed. According to the 1989 armourer’s manual, provided for the ACR trials, the G11 is made up of a total of nearly 450 individual parts – ranging from its barrel to sling attachments, from the sight assembly to the hinge of the magazine passage’s spring loaded dust cover. An impressive 144 parts make up the G11’s breech assembly. Thankfully, the field stripping process is relatively simple considering how complex the action is. I’m still not sure I would have liked to have tried it in a muddy field, at night, under fire.

The first step to disassembling the G11 is to ensure the weapon is clear by pushing the cleaning brush, which is handily stored in the rifle’s pistol grip, up into the breech. The butt assembly is then removed, this is held in place by a pair of plastic locking tabs at 12 and 6 o’clock. These plastic clips are reportedly prone to breaking as is the weapon’s folding plastic cocking tab – which is incidentally missing from this rifle.

Once the butt assembly has been removed we get our first look at the action in all its clockwork glory. The next step is removing the control disk, that sits on top of the breech cylinder, to do this the retaining catch has to be moved clockwise out of the way and then the disk’s clamping spring has to be depressed. Then you can lift the disk off to find the cylinder beneath it.

Close up of the underside of the G11’s action (Matthew Moss)

The breech cylinder is the piece that rotates 90 degrees to allow rounds to feed in from above. Inside the cylinder is a user-replaceable chamber piece. According to Heckler & Koch’s literature, the chamber had a lifespan of just ~3,000 rounds, although they hoped to up this to over 6,000. To free the cylinder the retaining catch is again moved clockwise and the cylinder can be pushed up out of its recess.

The chamber is square to accommodate the G11’s rectangular caseless 4.73×33mm rounds but the bore is circular and rifled like a conventional rifle. The chamber can be removed from the breech cylinder by removing the retaining spring that holds it in place. This is as far as a standard field strip, as prescribed by Heckler & Koch, would normally go for a soldier in the field. The manual actually has a warning ‘stop’ page which tells soldiers that only armourer’s with the proper tools should disassemble the weapon further.

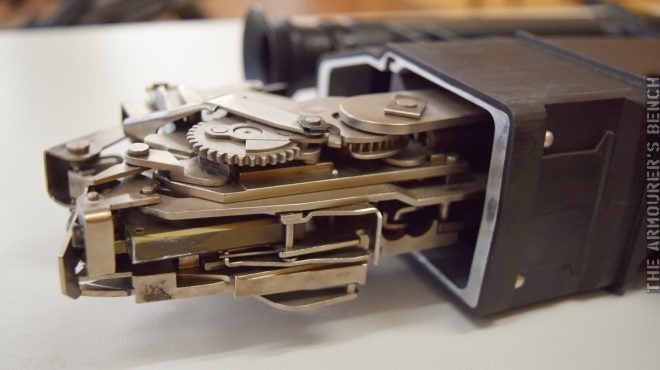

A close up of the two main gears that transfer energy from the gas piston’s operating rod to the rotating breech cylinder (Matthew Moss)

I went a step further and removed the breech and barrel assembly from the imaginatively-named centre assembly. In front of the action is the rifle’s gas piston on the right and the recoil management system on the left that compensates for the G11’s recoil when firing in its 2,000 round per minute hyper burst mode. In the photo above we can see the two main gears which transfer energy from the gas piston, via a very stout operating rod, to the rotating breech cylinder.

In the video I show the process for disassembling the G11, then I attempt to explain how the action works before reassembling the rifle. Check the video out below:

If you’d like to see more photos of the G11’s internals I’ve posted some here.

From these photos and in the video we can see not only just how complex the G11 was but also how ambitious it was. The G11 is a fascinating footnote in small arms history, an attempt to move into the next generation of firearms technology by utilising an ingenious action and advanced ammunition.

Your Privacy Choices

Your Privacy Choices