We at TFB recently had the opportunity to visit Federal Premium at their Anoka, MN ammunition plant for a factory tour. We were able to discuss a lot of the new products they have introduced this year, and it is a lot! Federal Premium has announced 34 NEW products to the market just in 2018. Everything from…

- Action Pistol Syntech Ammunition

- Hydra-Shok Deep Ammunition

- Grand Slam Turkey Loads

- 3rd Degree Turkey Loads w/ FliteControl Flex Wad & Heavyweight TSS Shot

- Federal Premium Gold Medal Sierra Matchking .224 Valkyrie

…and those are just a small number to name a few. In fact, this specific year has seen the most new product introductions in the history of Federal Premium’s long legacy of manufacturing.

Aside from conversing about their newest offerings to the market, we were afforded a factory tour of Federal Premium which we were truly grateful for because it is very rare to sneak inside their warehouse for such an intimate look. While Federal Premium does not allow for photography if you ever venture inside their factory walls they did provide us with a lot of phenomenal photos from their factory floor.

If you are wondering… why no photography?… it is primarily out of respect for the ammunition contracts that they hold. I was peppering the guys at Federal with questions like… how many rounds does this machine pump out?… what’s the output of this monstrosity on an average day?… how much raw lead does this process per hour?… Most all of their responses came with a smile on their face and a twinkle in their eye as they said: “A lot.”

Vague, yes. Accurate, yes. Appropriate considering nearly everything they produce is under contract in some shape or form, yes. I was hoping to hear some daunting specific number, but truth be told most of their machines (depending what they are) have the capacity to pump out millions of rounds a day. So with all of that being said, let’s get into some good ol’ fashioned ammo porn!

Pallets of Raw Lead Ingots awaiting to be processed for various Ammunition Components

Components getting Prepped to make their future Journey into Ammunition

Brass getting Tumbled to a Clean Shine

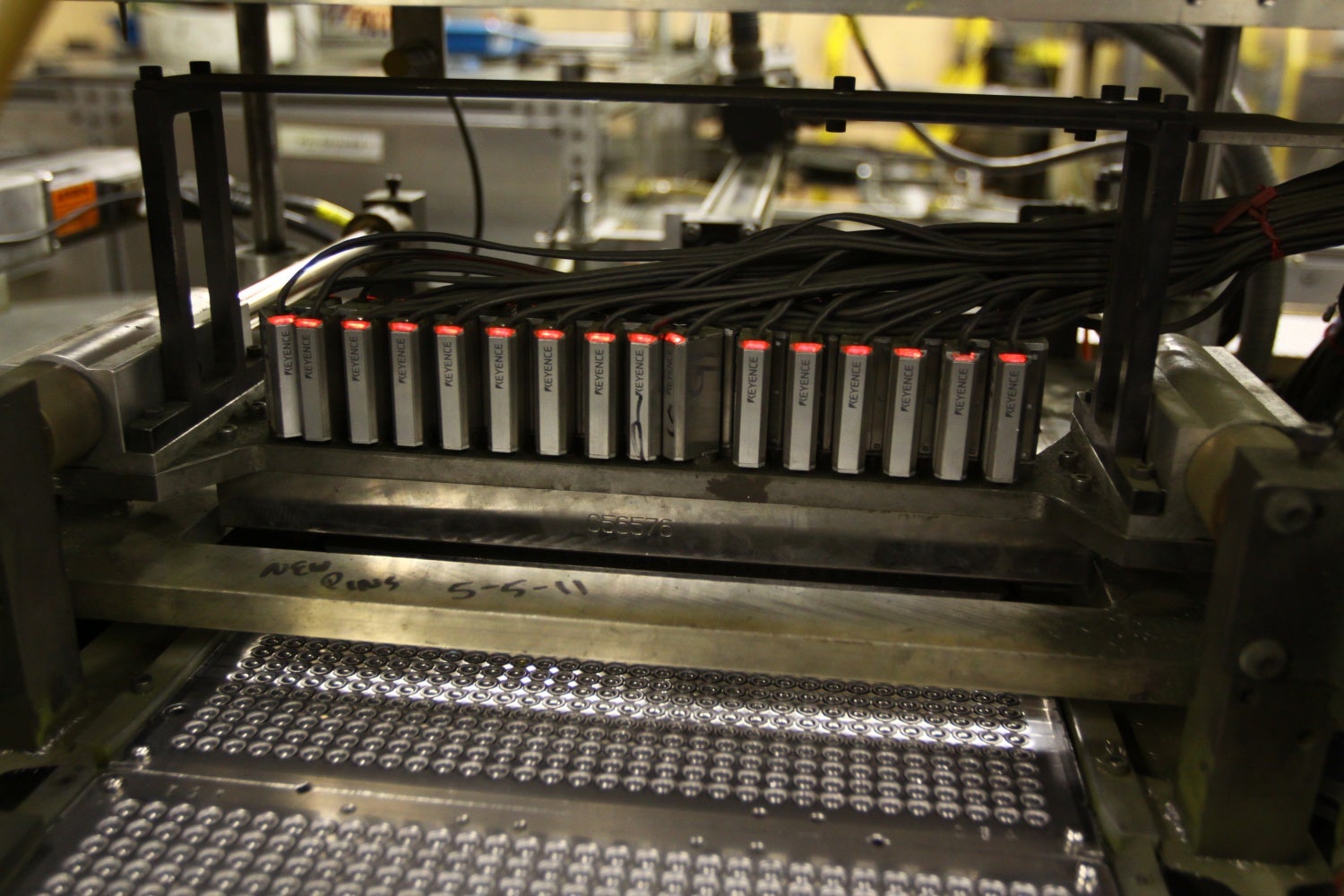

Handgun Ammunition receiving a thorough Examination for Quality Control

Rifle Ammunition taking a trip through the Merry-Go-Round to the Next Stage in the Process

Rifle Ammunition stepping up to the Mirror for a Closer Look to Maintain Quality Control

Rifle Brass getting Heat Prepped on its Way to become real Ammunition

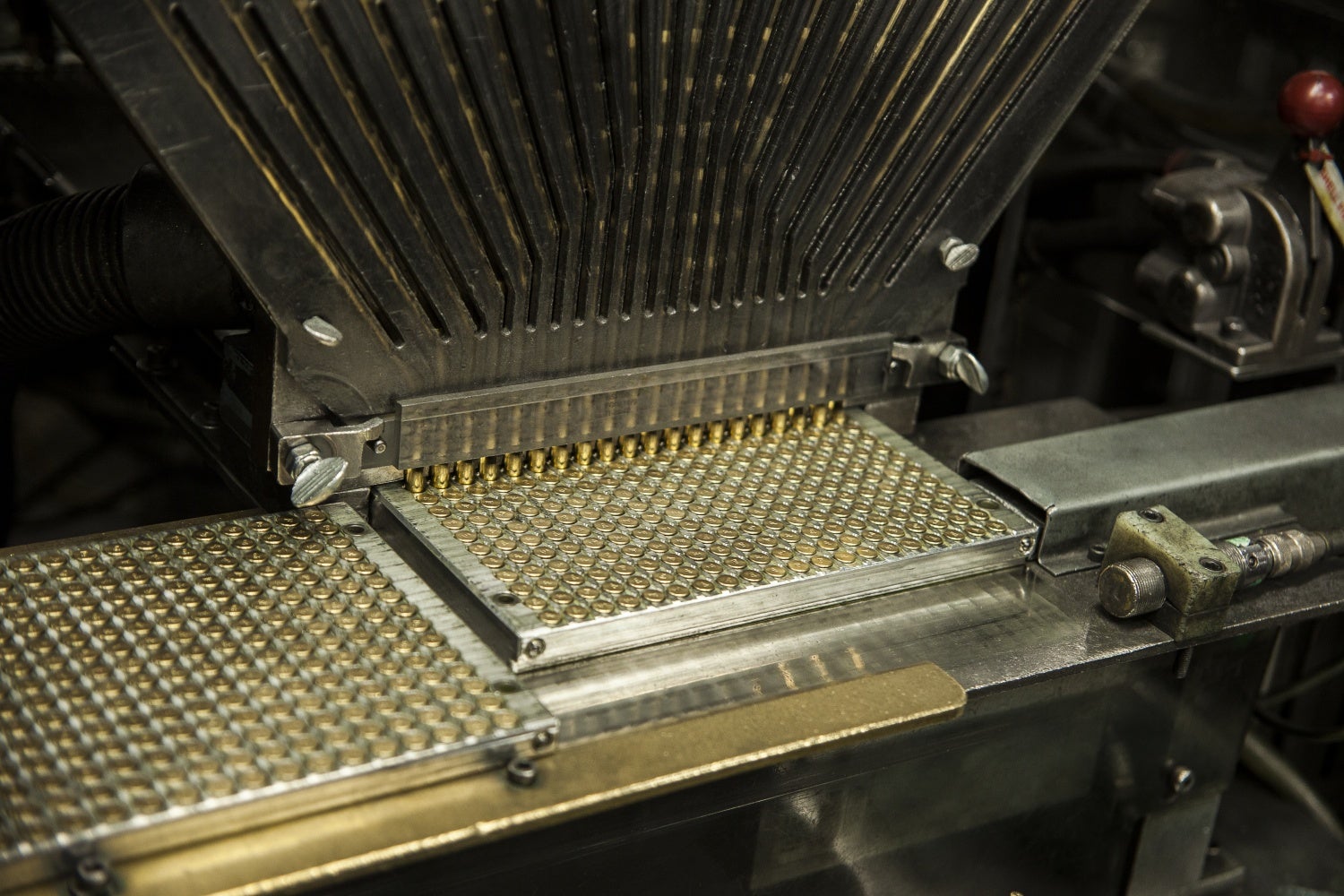

Brass getting Piped down into Trays to soon be Fed their Primers, Powder and Bullets

Rifle Brass going through the standard Heat Treatment process better known as “Annealing”

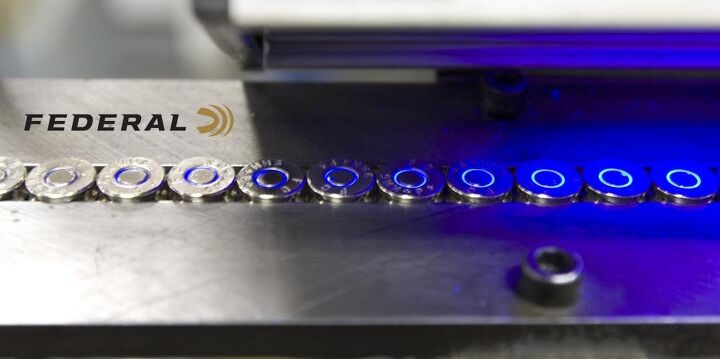

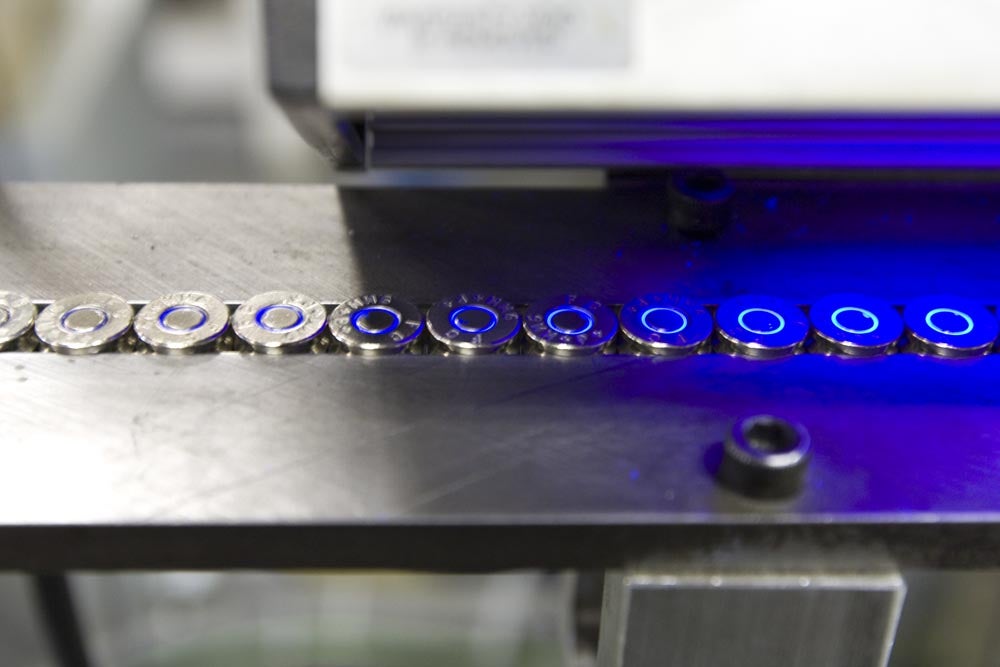

Primers getting Laser Inspected to ensure a proper Seat and Alignment into the Primer Pocket

Federal Premium got its start back in 1922 and it is truly astonishing to see some of those original machines churning out ammunition along side 21st century technology equipped with lasers. In fact, the strength and sheer colossal size of some of those old machines are required for the needs of today’s ammunition. Federal leans heavily on the capabilities of some of those veteran machines that just keep punching the clock and working.

Throughout the years Federal Premium has always found ways to give back to hunters and shooters. They have aligned themselves in conservation efforts with the National Wild Turkey Foundation (NWTF), the Rocky Mountain Elk Foundation (RMEF) and Pheasants Forever just to name a few. They also invest in our youth through such organizations as the Boy Scouts of America.

While making terrific ammunition and earning a profit for their employees is the name of the game, it is always important to give back to where you might have come from. Moreover, ensure the next generation of shooters is prepared to carry the torch of responsibility that comes with the shooting sports. Federal Premium is contributing in a plethora of ways to ensure all of those things happen.

While we got close to a “3 hour tour” (Gilligan’s Island reference.. the young kids won’t get it), it went by incredibly fast! Thank you again to Federal Premium for giving us a look behind the scenes of their factory and allowing us to share these photos with you; our readers! Thank you Federal!

Your Privacy Choices

Your Privacy Choices