“Novel Combustible Cartridge Cases for Next Generation Small Arms Ammunition” – this is precisely the title of a solicitation of the US Army published on the website of a US Government program called SBIR (Small Business Innovation Research).

Cased Telescoped ammunition and weapons (LSAT) developments by Textron Systems designed for the same goal of weight reduction

As the name of the solicitation implies, the Army is looking for a new material to replace the current metallic cartridge cases of the small arms ammunition. It must be a hydrophobic polymer material that would be possible to form into cartridge case shape. Most importantly, the material must be completely combustible without leaving any residue. Obviously, it also has to be a non-toxic one. The Army also requires that the ammunition weight reduction must be 50% with equal or superior ballistic performance compared to the current ammunition. Supposedly, it will be also easier and cheaper to manufacture.

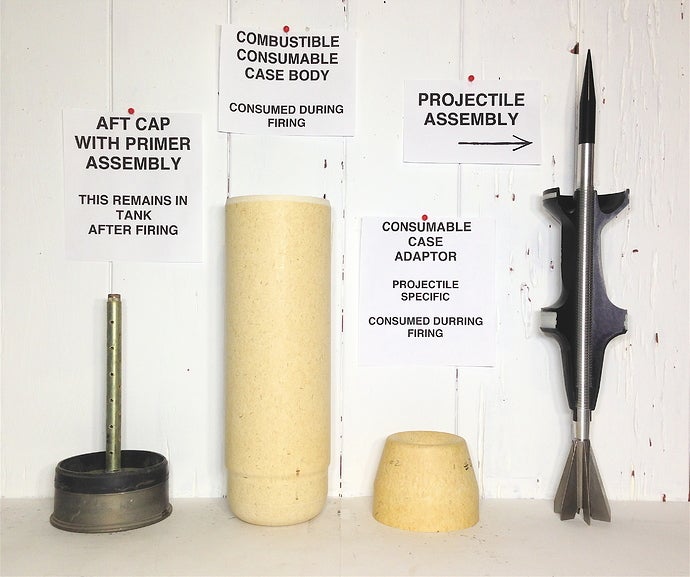

Tank ammunition with a semi-combustible case

I think this technology will also mean redesigning the weapon systems, too. With the locking and operation mechanisms of current issue weapons, it would be challenging to ensure a seal of the chamber with a completely combustible cartridge case.

I’ll quote below the text of this solicitation:

TECHNOLOGY AREA(S): Materials

OBJECTIVE: Develop and test lightweight combustible case materials and designs for small arms ammunition to reduce weight without sacrificing ballistic performance and long-term reliability.

DESCRIPTION: Weapon system advances have resulted in the infantry soldiers carrying additional gear to enhance their combat effectiveness, but at the cost of increased logistics burden. To ensure that America’s soldiers maintain their overwhelming combat edge into 21st century, decreasing soldier loads has become a top priority for the Army. In this regard, one of the heaviest burdens for soldiers is their ammunition. However, the high cost of lightweight metal materials and the associated manufacturing costs represent a significant part of the affordability challenge to reduce weight. Attempts in the past 50+ years to use lightweight polymers to replace brass can only reduce the weight by about 25% and has not yet proven successful to achieve the ballistic performance and long-term reliability. Combustible cartridge case technology is successfully used in large caliber ammunition systems to eliminate the logistical burden of disposing of unconsumed packaging after firing. Combustible cartridge cases bring additional advantages in comparison to metal cases such as reduction in barrel wear, enhanced firing energy, increased firing rate and reduction in charge costs. At the same time combustible case materials offer protection of the propellant in the handling, storage, and loading phases, making it a good candidate to replace metallic cases. Recently, there has been significant interest in pursuing existing felted fiber combustible cartridge case technology in small caliber weapon systems to achieve the lightweight ammunition goal. However, it is challenging to apply felted fiber technology to small arms ammunition to replace the conventional brass case. The technical hurdles include the combustible resin inherently lacking mechanical strength, high porosity, vulnerability to penetration of water and water vapor, and problems related to materials used for fabrication, and complete combustion. Therefore, despite numerous advantages of felted fiber cartridge cases to metal cases, there are still barriers to incorporation of the technology in small caliber ammunition. This SBIR project shall include a multidisciplinary research and development effort focusing on mechanics, materials science, physics, chemistry, design and numerical modeling and simulations, in order to identify and characterize novel combustible polymeric materials, optimize small caliber cartridge case designs, and determine production feasibility. First, this effort shall develop or identify combustible polymeric materials for small arms cartridge case applications. Included in this development is the study of the material residue after burning of the selected combustible polymeric materials. Analysis of mechanical and physical properties of the combustible materials at various temperature, humidity and treatments shall be performed. Secondly development efforts for small arms cartridge case design using combustible polymeric materials shall be carried out. Dynamic finite element analysis simulations shall be conducted to validate the internal and exterior ballistic performance of the proposed cartridge case designs. Lastly, an investigation shall be completed on the impact of the ammunition environment on the mechanical and physical properties of the selected combustible cartridge case materials. The production capability and feasibility of the proposed lightweight combustible cartridge cased small arms ammunition shall also be assessed. The success of this novel combustible case material and design will enable a technology transition to PEO Ammunition, delivering lightweight small caliber ammunition to the U.S. Army. By reducing the ammunition weight, soldiers will be able to carry stronger armor protection and additional gear without compromising their mobility, thus achieving tactical objectives with improved soldier survivability. The novelty of this topic is that it addresses a long term need in small caliber munitions through new and novel material technologies. While felted fiber and even celluloid based combustible cartridge cases have been implemented for large caliber propulsion systems, there has been little work done to transition to small caliber munitions, due to the issues described above. This SBIR project provides a unique opportunity to study both novel combustible case materials for small caliber ammunition but also the design of the ammunition, in order to provide the soldier with a lightweight next generation system solution. Parameters/Metrics which these cartridges must meet: * The cartridges should be completely consumed. No residue should be left behind after combustion. * The cartridges should be completely hydrophobic. * The material used to fabricate the charges should be relatively easily formed into the desired shapes. * The cartridges must be made of a material 25% mechanically stronger than currently used in combustible cartridge cases in large caliber munitions. * The ballistic performance of the new cartridges should be equal or better than existing ammunition. * The weight should be 50% of that of legacy cartridges. * There material should be non-toxic. * The cartridges should be able to withstand standard operating conditions. * Aging should not have significant effects on the performance or safety of the cartridge cases.

PHASE I: Develop novel small arms cartridge case design concepts using novel combustible polymeric materials. Conduct dynamic finite element analysis simulations to validate the interior ballistic performance of the proposed combustible cartridge case designs. Identify, develop and test combustible polymeric materials for small arms polymer cartridge case applications. Study the material residue after burning of the selected combustible polymeric materials. Perform analysis of mechanical and physical properties of the combustible materials at various temperature, humidity and treatments.

PHASE II: Review the results from the Phase I feasibility study. Optimize the combustible material selections and refine the cartridge case designs. Investigate environmental effects on the mechanical and physical properties of the selected combustible polymer materials. Develop proper tooling, molds and build actual prototype cases on proposed combustible small arms cartridge case designs. Conduct advanced 3-D finite element analysis modeling and simulation to validate the ballistic performance of the proposed cartridge case with combustible material at extreme low temperature or cook-off temperature in hot weapon chamber. Conduct ballistic testing to measure chamber pressure and muzzle velocity and inspect the residue material. Assess production capabilities and feasibilities of the proposed lightweight combustible cased small arms ammunitions.

PHASE III: If this program is demonstrated to be successful, this combustible polymeric casing technology can be applied to military and civilian applications. Military application includes lightweight cartridge cases for small arms (5.56mm, 7.62mm and 0.50 calibers), medium caliber (20mm, 25mm, 30mm and 40mm) as well as large caliber (60mm, 81mm, 105mm and 120mm) ammunitions. The likely transition partner is the Program Executive Officer for Ammunition. Civilian applications include hunting, sport shooting, and law enforcement.

SBIR is a US government program that helps the domestic businesses to engage in Federal research and development programs which has the potential to be commercialized. These programs include projects initiated by a number of US Government federal executive departments including the Department of Defense. Besides the program that is the subject of this article, there are a number of other defense and small arms related programs in the list of solicitations. You can read the list and brief descriptions of other SBIR programs by clicking here.

Sources:

“A18-013: Novel Combustible Cartridge Cases for Next Generation Small Arms Ammunition”. (2018, January 08). Small Business Innovation Research. Retrieved From: https://www.sbir.gov/node/1409921

Images from www.textronsystems.com, www.cartridgecollectors.org

Your Privacy Choices

Your Privacy Choices