Last week, Miles V and I got a chance to check out Cabot Guns. They are only 40 minutes from my house. Nestled in a corner of the Penn United Technologies building across the street from the Lernerville Speedway is a treasure trove of high end 1911s made of some really exotic materials.

Most of the manufacturing of Cabot’s 1911s is performed in Fort Wayne, Indiana. However the office in Cabot, PA is their headquarters. Miles and I met with Founder and CEO Robert Bianchin. Rob started Cabot Guns with the idea of making the 1911 100% in America with only American sourced materials. No one was making high end 1911s with a discriminating eye for detail. He wanted tolerances that exceeded normal expectations and it shows in the guns he has made.

When we walked into Rob’s office it was a smorgasbord of rare and exotic materials. Sure there were some 1911s but I was more interested in the materials.

A display case full of interesting materials used for grips and small parts.

“What’s that rock” “That’s not a rock. It is a T-Rex Vertebrae”

Assorted fossilized mammoth tooth and extinct giant elk antler.

Meteorite Space Gun

My sole purpose for speaking with Rob was to find out more about the Big Bang Set. My wife has a PhD in Material Science Engineering and studied metals while obtaining her doctorate. So I have a slightly higher than layman understanding of metals. The Big Bang Set intrigued me because of the material used. The Gibeon meteorite is an iron/nickle alloy that fell from space. Simply taking a chunk of it and machining it is one thing. But understanding the material to know if it can be made into a gun is an entirely different approach all together.

Cabot had already spent years perfecting their machining but they spent a year understanding the meteorite as a material. Stress tests were performed on components to see how they could handle the forces applied to them when used and fired. One of the biggest concerns I had was the fact that the material is not homogeneous like a nice piece of billet. Naturally formed metals and rocks could have inclusions or voids which would could cause a catastrophic failure if the material broke. They cut into the meteorite and luckily they did not find any glaring issues. XRays were performed for further analysis.

Other concerns were rust. Certain parts of the iron based meteorite would start oxidizing as soon as it was exposed to the air. So they had to find ways of halting that process. Next up is how the material would look. A lot of effort and care is spent on presenting the material and showing its character. Rob refers to the natural texture you see in the meteorite grips as the “bark” of the meteorite. It looks like chunks of the material were removed however those were left there to show off the meteor. The cross hatched texture you see in the frame are known as the Widmanstätten patterns. Once the material is machined it looks like any ordinary hunk of metal. It is like Damascus so the patterns are only brought out by a chemical process.

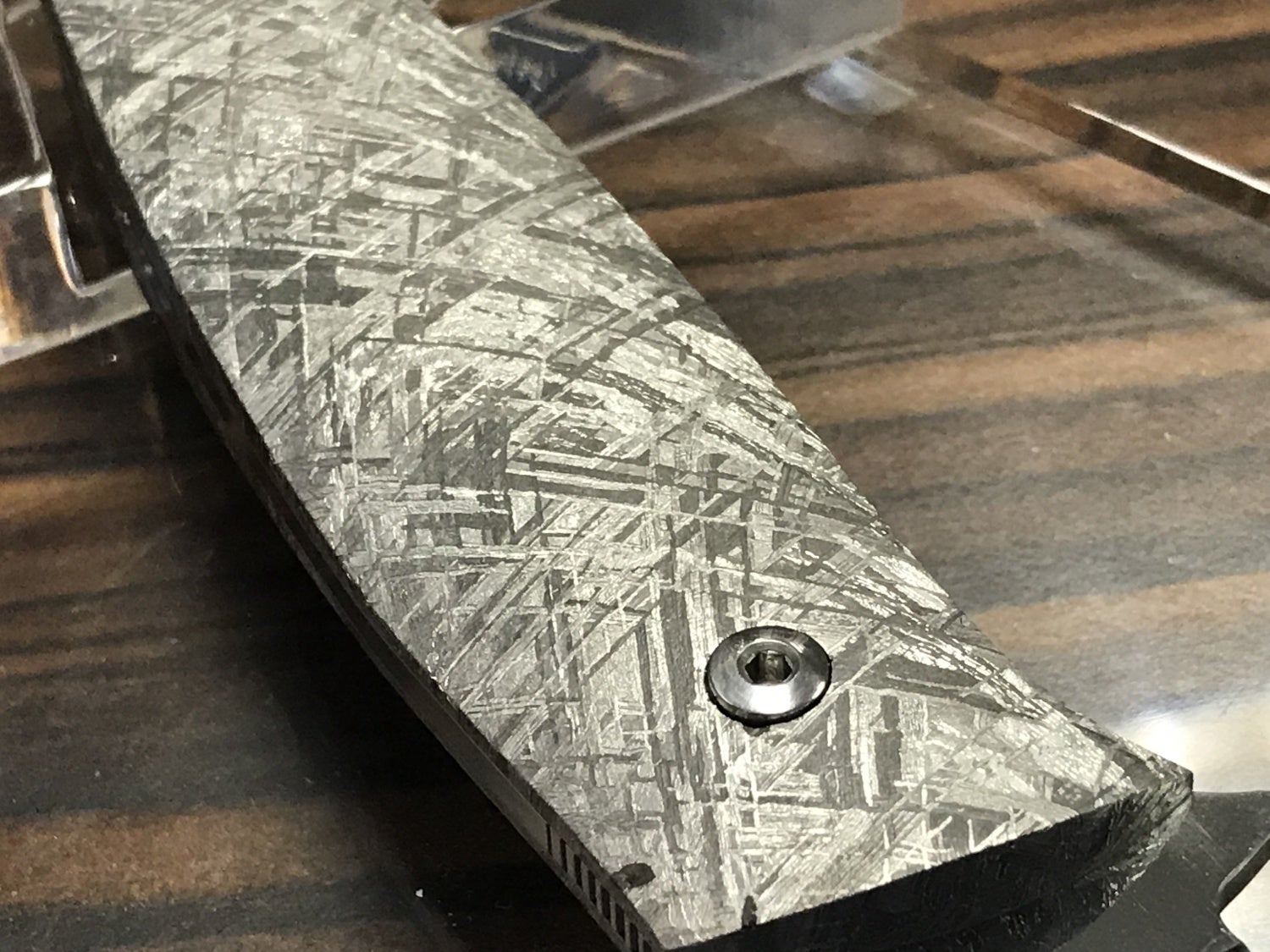

Below is a limited edition collaboration knife with Sandrin Knives. The blade is Tungsten Carbide but the grips are made of meteorite.

The Big Bang knife costs $10,000 USD.

You can see the Widmanstätten patterns in the grip.

The Widmanstätten patterns are long grains in the metal. When you look at metals in a scanning electron microscope and use a EBSD (Electron Back Scatter Detector) you can see these grains and find out their orientation. This is important for studying and understanding the material. The long grains seen here are only found in meteorites. They do not exist naturally on Earth. It has to do with the slow cooling as the meteorites travel through space. millions upon millions of years. In some cases billions of years.

The Timetraveler 1911

Unfortunately the Big Bang Set was not in the Cabot Guns office but the Timetraveler was.

Take a look at the grip. It has been polished. According to Rob the color you see is from a heat treatment. I suspect it may be akin to case hardening.

The grips, magazne base pads, trigger and sights are all made of meteorite.

Other Exotic Materials

Besides meteorite, Rob travels to gem and knife shows looking for the next material he will use in a gun. You saw the T-Rex vertebrae and mammoth tooth slabs. Well they have made Damascus 1911s in the past but nothing like what they are working on now.

Robert Eggerling is a Damascus wizard. He is known for his “mosaic damascus” in the knife world. Check out the piece Rob had as a sample. I had no idea that geometric shapes were possible in Damascus let alone made intentionally. Eggerling is also a PA resident although he is on the other side of the state. He has made a billet for Cabot which they will be making into a 1911.

Below is a piece of steel from Japan.

As a joke here is a 1911 0% lower. This slab of steel is proof that they make all of their 1911s from scratch.

Here is a hand engraved Cabot 1911 that they had done.

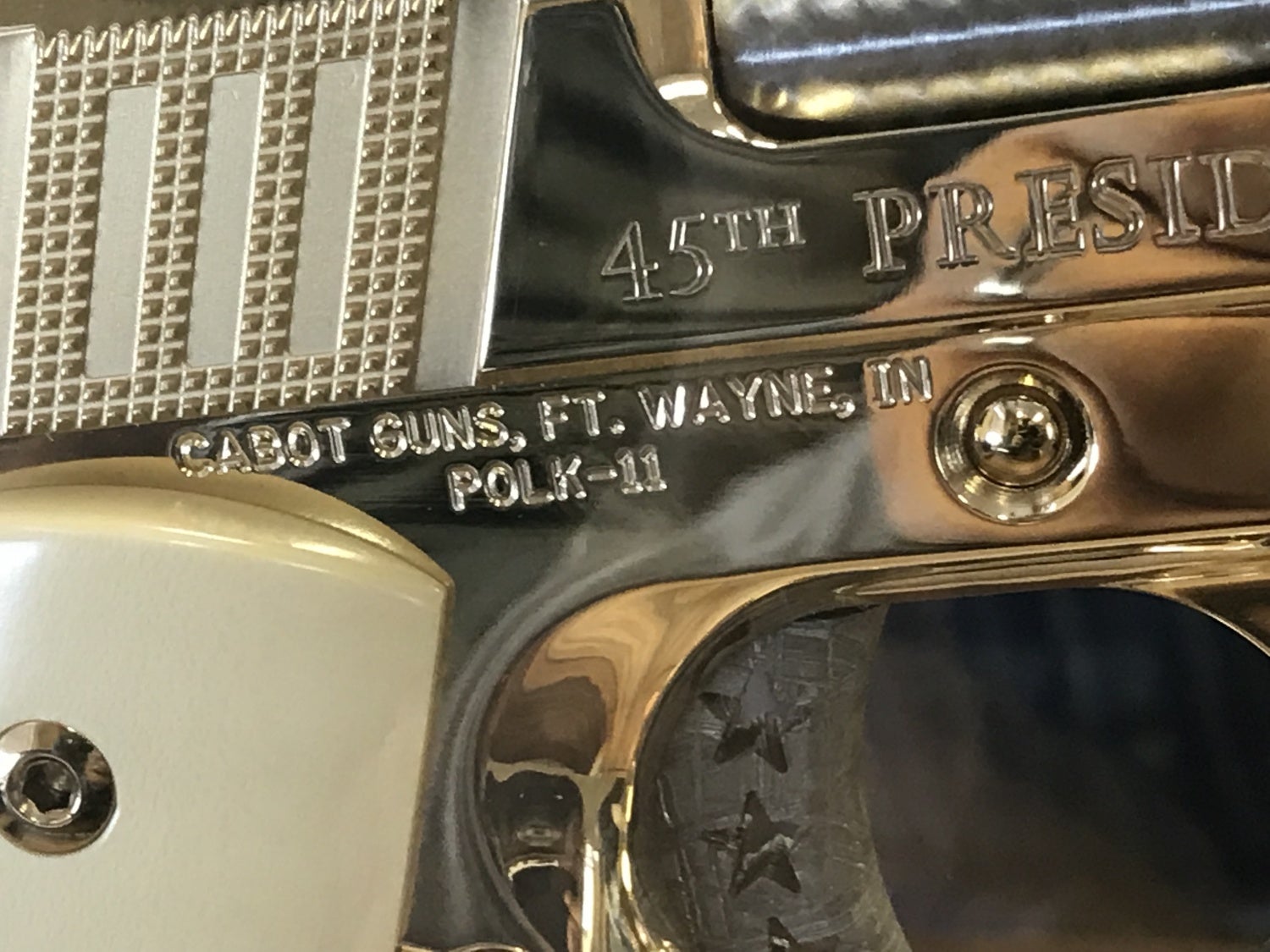

TRUMP 45

Cabot is releasing their TRUMP 45 1911. Since Trump is the 45th president it is kismet to make a 1911 commemorating this triumph. Their will make forty five TRUMP 45 1911s. They will be serialized 1-45 however each serial number will correspond with the 45 Presidents of the United States. Miles and I saw the eleventh TRUMP 45 which was serialized POLK11. Rob did mention that one of the TRUMP 45s will be given to the TRUMP family. Washington-1 and Lincoln-16 serial numbered TRUMP 45s have already sold for $50k USD each.

This 1911 has a meterorite trigger and front sight.

Obama-44 will be a mirrored left handed version of the TRUMP45. They did think about doing this for all the democrat serial numbers but thought it best to do it only for the Obama-44.

A huge thanks to Rob for taking the time to speak with Miles and I just before SHOT Show. The moons, planets and meteorites aligned for this meeting to take place and I am glad it happened. The amount of focus and attention to detail is astounding at Cabot. These are the Rolls Royce of 1911s. Unfortunately due to time schedule we were unable to shoot a Cabot 1911. Hopefully I will get a chance to revisit them and test fire them to see how well they shoot.

Your Privacy Choices

Your Privacy Choices