John S. is a guest writer who is concentrating on the subject of body armor. This is his first article on TFB.

We get it, body armor is a complicated subject. There are many kinds of materials, with their own distinct advantages, disadvantages, and properties. Then there’s different ratings, shapes, and cuts. To add to that, it doesn’t help that some manufacturers don’t disclose all the information you should know as the end user. In this article, I am going to shed light on some properties, pros, and cons of the most common types of Ceramic body armor, as well as AR500 or steel body armor. I hope to clear up some common misconceptions about these types of armor and provide general information so you can make an educated choice when choosing what armor to trust your life to.

This is not blanket information for everything nor does it cover everything, not all armor is created equal, even those in the same category. There will be exceptions and I will speak about a few of them.

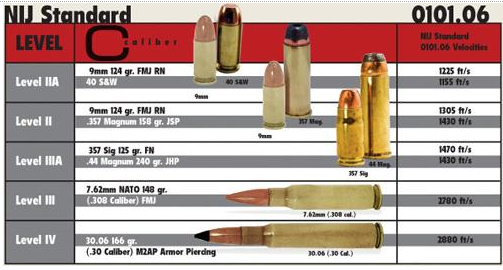

For our purposes, we will only be discussing rifle threat rated body armor, specifically NIJ 0101.06 Level III and Level IV.

(NIJ 0101.06 is the most up to date NIJ rating system, there are others such as 0101.04 or 0108.01, but those are previous outdated revisions).

This article will demonstrate the basic necessities of the important topics when dealing with understanding body armor.

The National Institute of Justice (NIJ) rates and tests rifle threat rated body armor and what calibers of ammunition they are rated for in the following conditions:

(These are not all the tests, these are just the important ones relevant to this discussion).

1) For armor to be rated NIJ Level 3, it must stop 6 rounds of 7.62x51mm NATO Ball (147gr) fired from 15m at a velocity of 2780 (+/-30) FPS.

2) For armor to be rated NIJ Level IV, it must stop 1 round of .30-06 M2-AP (166gr) fired from 15m at a velocity of 2880 (+/-30) FPS.

3) Both require a back-face deformation of less than 44mm.

4) Armor also undergoes a drop test, where a 10lb weight is strapped to the back of the plate, and it is dropped onto a hard-concrete surface at a 90-degree angle from no less than 4 feet.

The armor is not dropped on its edge, but on the strike face.

REMEMBER, to officially earn the rating they are required to ONLY test against that caliber of ammunition at that weight and velocity.

US Military issued Ceramic plates are not NIJ certified, they are tested to Mil Spec standards. I am going to include some rough ratings as the information is not available to the general public. (Thank you to Bulletproofme.com for having this information on their website).

1) SAPI: Must survive 3 hits total in conjunction with an interceptor vest containing soft armor backing from, AK-47 (7.62x39mm API) Armor Piercing Incendiary, M16 (5.56x45mm/ .223 M855/ SS-109) Green Tip, Dragunov (7.62x54mm R-LPS) Russian Light Penetrating Steel.

2) ESAPI: Must survive one hit total and a second hit 60% of the time in conjunction with an interceptor vest containing soft armor backing from: .30-06 M2-AP.

Some terms to know:

- In Conjunction With (ICW): This means this armor (generally Ceramic or Polyethylene) must be worn in conjunction with soft armor (generally 3A) to reach its maximum efficiency.

- Standalone: This means this plate will stop its maximum rated threat alone and without need of soft armor backing.

- Single Curve/ Multi-Curve: This is how many bends are in the armor plate itself.

Single curve means the plate has a single curve, vertically along the middle.

Multi-Curve means that there are multiple curves (duh) most commonly the edges are curved in to contour better to your body.

For extended wear, multi-curve is suggested as it is significantly more comfortable.

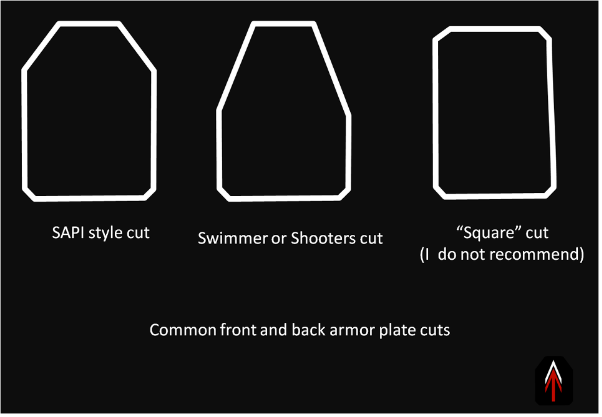

Different cuts of armor: (Thanks to AT Armor for the great picture)

Proper sizing and fitment of armor plates:

(Remember, you buy a vest to fit your plates, not the other way around)

General rule of thumb is the edges should line up with your nipples or cover them slightly.

Wear your front plate so the top of the plate is two finger widths below where your sternum ends. 10×12 is medium for “Sapi” style cut… it is not one size fits all.

Now that we’ve gotten past the scientific part, let’s talk about some of the common misconceptions when it comes to body armor.

- NIJ Ratings do not “stack up” they are non-inclusive. Just because a plate is rated Level IV, does not mean it will stop level III threats.

As I mentioned before, it is officially rated ONLY for the ammunition tested, at the tested velocity.

For example, just because a Level III plate is tested against M80 Ball, does not mean it will stop M193 or M855 fired out of a standard 16” AR-15.

I am not saying it won’t, I am not saying all Level IV plates cannot stop M80 ball, or all Level III plates cannot stop M193.

The most common example of checking threat ratings would be with ultra-light versions of rifle threat plates such as UHMWPE (Polyethylene, Dyneema). These plates are made of a type of Polymer. Some versions of these plates are not rated for higher velocity rounds such as M193 or M855, it is important to check with the manufacturer to make sure that these rounds have been tested for when choosing ultra-lightweight Ceramic/ Polyethylene plates.

Most level 4 plates will stop M80 ball or M193, it’s nothing to worry about, this is mainly something to keep in mind for Polyethylene or steel plates.

Which moves onto our next point.

- “Level III+” or “Level IV+” is NOT an official NIJ rating. The “+” is a label that manufacturers add on themselves and is not an official rating.

This normally means that the plate is special threat tested against rounds other than what NIJ requires of them. Often you will see Level III+ or even Level III++ to denote that a plate has been tested to stop a special type of ammunition, this could be M193, M855, M855A1, etc. Manufacturers will say what special threat they are tested against.

- Ceramic is not as fragile as everyone makes it out to be. It seems that many people are under the impression that Ceramic armor is like glass and needs to be babied otherwise it’s going to shatter and lose all its ballistic capabilities.

I have mentioned before that Ceramic plates must undergo a drop test with a 10 pound weight, dropped from 4 feet onto concrete.

Now… this does not mean you should go throwing your Ceramic plates across the room or using it as a hammer.

You should not drop your Ceramic plates, but if it is dropped once on its strike face from table height, you’re likely ok.

Edge strikes are what you should be concerned about.

- The 5 year “expiration date” armor manufacturers put on armor is not a firm guideline. This expiration date says that through varied conditions, this piece of armor should last 5 years. If you’re wearing your Ceramic armor into combat 8 months out of a year, it is likely not going to last 5 years.

However if your armor is lying flat, in a cool dark area (or even just a regular room) it likely will last well beyond 5 years.

This applies to both hard armor plates as well as Kevlar soft armor panels (if stored correctly).

- “Ceramic is not Multi-hit”

This is not entirely false, but it is also not completely true. As I mentioned before, an NIJ Level III plate must stop six (6) rounds of 7.62x51mm M80 Ball. That includes Ceramic plates that are rated evel III. Most Ceramic plates are going to be able to take a few rounds of M80 Ball, if it can stop M193 it should stop a few rounds of that as well. The main place where this would apply would be for .30-06 M2-AP, not all Ceramic plates can stop two rounds of that.

- MIL-A 46100 steel armor is NOT rated to stop .30 cal (.30-06 M2-AP) at a 90 degree angle of strike.

This type of steel was designed as vehicular armor, and was therefore tested with vehicular usage as its end use and not body armor.

MIL-A 46100 steel armor is rated to stop .30 cal when the plate is at a 30 degree ANGLE. Angling armor increases its effective thickness.

- Putting armor on the ground and shooting it in your back yard is not a valid means of testing the ballistic capabilities of said armor.

I’ve linked the parameters for NIJ testing and a video. Unless they’re at a minimum backing the plate with clay and using a chronograph, it doesn’t mean much. (Unless it penetrates… if it penetrates then clay won’t matter) Back-face deformation is just as important as penetration/ non-penetration.

Now that we’ve gotten past some of the common misconceptions, let’s look at some of some of the common materials making up rifle threat rated body armor and some pros/ cons and information on them.

Part Two, about the differences between Ceramic and Steel armor will be availible here when it comes online.

Sources:

- National Institute of Justice 0101.06 Standard:

https://www.nij.gov/publications/Pages/publication-detail.aspx?ncjnumber=223054

(PDF) https://www.ncjrs.gov/pdffiles1/nij/223054.pdf

-pg. 4 (Level III/ IV testing parameters)

-pg. 36 (Drop testing)

-pg. 49 (Back-face deformation)

- MIL-A 46100 D Standard:

(PDF) http://everyspec.com/MIL-SPECS/MIL-SPECS-MIL-A/download.php?spec=MIL-A-46100D_INTERIM-AMENDMENT-2.020498.PDF

-pg. 22 (MIL-A 46100 D .30 cal testing @30 degrees)

- SAPI/ ESAPI approximate ratings:

http://bulletproofme.com/Body_Armor_Accessories_Rifle_Protection.shtml

- Polyethylene Plates weakness against AP/ Heat & Cold

http://www.bulletproofme.com/RP-Polyethylene.html

Further Reading/ information:

If you’re interested in more of this, here is some more reading to do and some videos.

- NIJ 0101.06 Standard (One of the sources for this article)

https://www.ncjrs.gov/pdffiles1/nij/223054.pdf

Shooting test for a Level IV plate:

https://www.youtube.com/watch?v=4vL-08x7T4I (Skip to 2:10)

Your Privacy Choices

Your Privacy Choices