Mark Serbu of Serbu Firearms has released a video showing that making a rifled barrel in home shop conditions and with corresponding tools is possible. Using a drill press to drill the bore, a hand drill to ream the bore and a bench vise to push the rifling button through the bore might not be the most efficient methods to make a rifled barrel. However, the purpose of the video is to demonstrate that it is possible. Let’s watch that video:

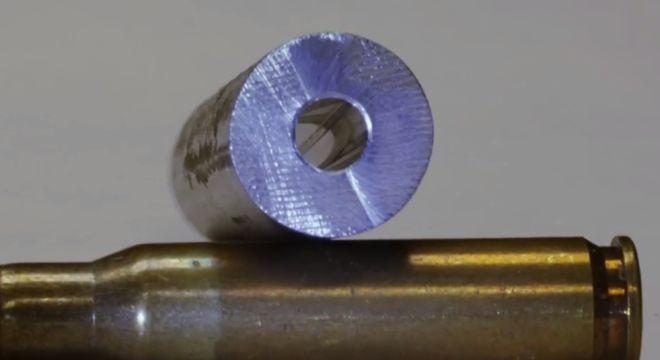

As Mark noted, it is quite interesting that when pushed into the bore (not pulled through it), the button will rotate itself and form the desired rifling pattern and twist rate. It won’t probably be a too precise twist rate without controlling the rotation of the button, but it still should do the job (impart rotation to the projectile) for a DIY barrel like that.

Note also how it becomes a much more accurate and faster process when doing the same on a CNC machine. I assume the same results can also be achieved using an old-school mill and/or lathe.

I think both the home workshop and CNC methods can work for making such short barrels only. Making a longer rifled barrel should be much harder or even impossible with that kind of equipment because of the deep hole drilling process. It would require special tools and proper skills/knowledge to accomplish such a task.

Your Privacy Choices

Your Privacy Choices