In yesterday’s article, we took a look at examples of two different methods of design, which I called “preference-driven” and “process-driven”. For these examples, I supposed two engineers from two different cultures – called “Romulan” and “Vulcan” after the aliens from the Star Trek universe.* In the “Romulan” example, we explored preference-driven design, where a final product is outlined by amalgamating preferred characteristics from previous works to create a desired whole. For the “Vulcan” example, we examined the more elaborate method of developing processes that can be fed data to procedurally generate characteristics as an example of process-driven design.

*To be perfectly honest, I’ve seen very little of Star Trek (perhaps as little as two episodes, and one of the recent films), but the respective characters of the aliens and their presence in popular culture fit the different design methods very well, so I ran with it.

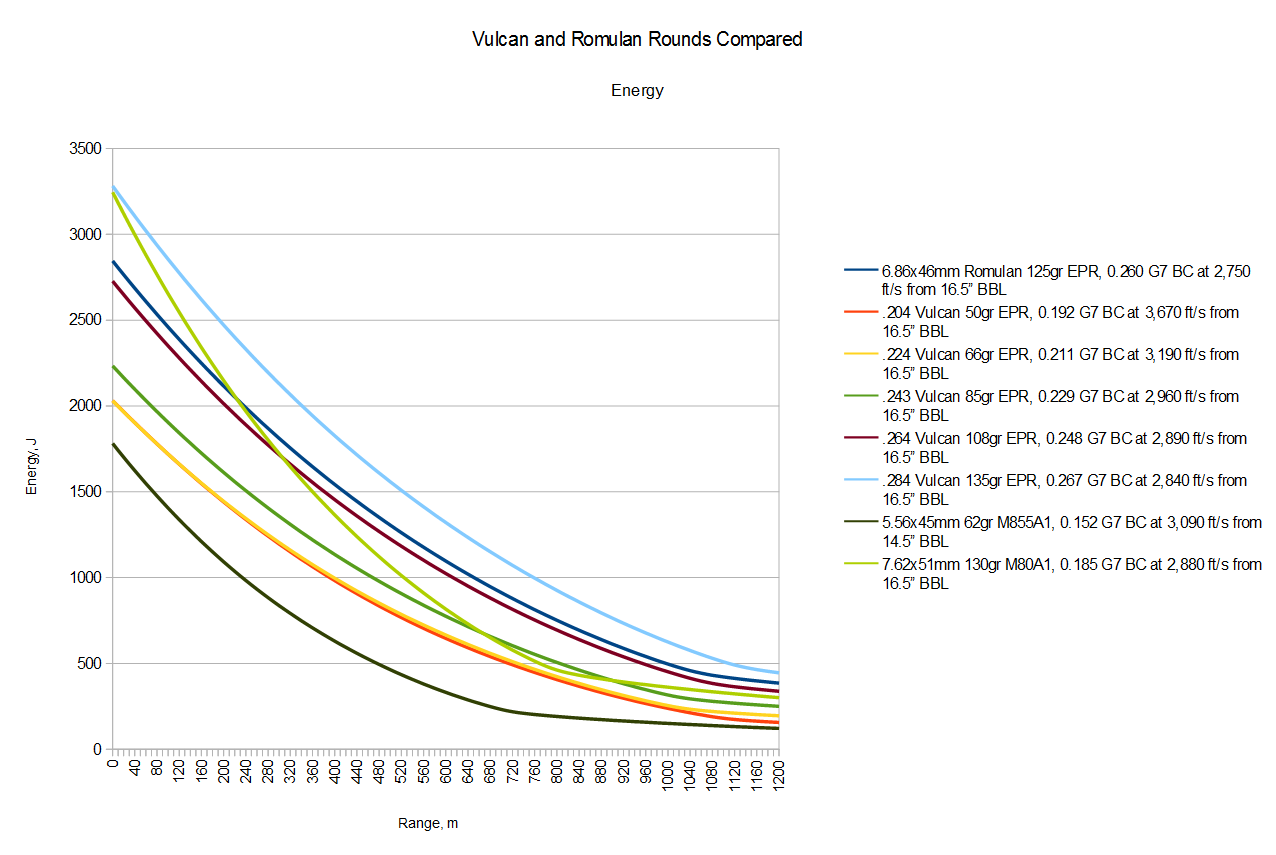

In this article, we will be taking a closer look at these examples, as well as embarking on some more in-depth discussion of preference- vs. process-driven design. But first, I’ve kept you all waiting too long already: We need some graphs!

You might want to open these in a new tab!

A few things are obvious from these graphs. The first is that the 6.86mm Romulan and .264 and .284 Vulcan rounds are all pretty big boy pants calibers. Both the 6.86mm and .264 start to exceed M80A1 for energy by just 200-300 meters, and the .284 Vulcan outright beats M80A1 for energy at all ranges. Also, the .224 Vulcan substantially out-performs M855A1 out to 700 meters due to its much lower drag bullet – after that distance M855A1 goes subsonic and is accordingly subject to far lower drag, allowing it to “catch up” somewhat with the still supersonic .224 Vulcan – although it never fully does. The .243 Vulcan, too, makes an impressive showing, beating M80A1 for energy out to 900 meters and remaining competitive out to 1,200 meters. Given how much lighter the .243 Vulcan is, this is really something. For drop at long ranges, the low drag bullets of all Vulcan rounds set them apart from both M855A1 and M80A1, but it’s the ultra-high-velocity .204 Vulcan that stands out the most here. That, coupled with the rather competitive drift characteristics we see for the round has me wondering whether a few years from now ultra high velocity .20 bores will be a staple of long range competition. It seems far-fetched now, but it follows the current trend: 6.5mm rounds like the 6.5mm Creedmoor and .260 Remington supplanted .30 caliber rounds like .308 Winchester and .300 Winchester Magnum, only to be supplanted themselves by 6mm derivatives like the 6mm Creedmoor and 6x47mm Lapua. It’s not so difficult to imagine those slick 6mms being replaced in turn by even more extreme .22 calibers rounds firing 90 grain VLDs, and the jump from that to .20 caliber is just one good low drag .20 cal VLD bullet away from possible. Yet, for military use, such extreme rounds really are too much of a good thing. It’s difficult to imagine such an overbore round giving the kind of barrel service life demanded of military weapons, so – even if such a thing comes to pass – it will probably remain in the competition world only.

With that out of the way, some personal history is in order. I have been designing virtual small arms rounds for about a decade, ever since I first became interested in the subject in my last two years of high school. During those years, I refined methods for creating facsimiles of practical small arms rounds until I eventually settled on the three-piece approach I have used for several years now. This process uses a combination of pressure computer, ballistic calculator, and solid modeling/CAD to approximate the internal and external ballistics and physical characteristics of different ammunition. While this method does not always produce realistic results due to limitations in the sophistication of the pressure computer (Powley) that I use, it does afford me the unique opportunity to perform comparative analyses on whole suites of different ammunition quickly and easily. Over time, I began to develop a refined process-driven method for creating new small arms ammunition to meet given requirements – a method I have dubbed the “spectrum study”. None of this is really anything new, and I don’t claim to have “invented” any of it. If anything, my process is cruder than mathematical engineering processes which have been in use for decades. In fact, I’m far from the first person to have performed a study like this in small arms, even. There was a study published in 1977 by the Center for Naval Analyses entitled A Methology for Selecting Small Arms Rounds which details very systematic and thorough process-driven engineering effort for small arms ammunition. It has been a huge influence on me, and I don’t think it would be too harsh to say my “spectrum study” is just a ripoff of the hard work on display in that paper. Anyone who found themselves riveted by my first post should do themselves a favor and read A Methodology.

On several occasions I have designed rounds via spectrum study, only to revisit those requirements with rounds designed preferentially, or vice-versa. In each case, I noticed that the rounds resulting from the spectrum study were substantially lighter and smaller than those designed “organically” (via preference-driven method), something which stuck with me. Discussing the subject with fellow TFB writer Hrachya, he convinced me to write an article on the subject, which led me to conduct the more controlled study published with the last article. In truth, conducting this study (not to mention writing up a subject so dry in such a way that would be engaging) was a challenge: By their nature, preference-driven and process-driven design methods are not directly comparable. The process-driven design will inherently adhere more closely to a fixed set of requirements than a preference-driven one, because the latter is determined essentially subjectively. As a result, keeping both experiments “controlled” relative to one another was difficult.

Some things I could control, however. All rounds in both experiments used the same projectile design and shape, a low drag EPR with a steel core, copper slug, and gilding metal jacket, average density of 8.53 g/cm^3, and an estimated i7 FF of 0.896. This model projectile was scaled in SolidWorks to .224, .243, .264, .284, and, for the “Romulan” round, .277 inches in diameter. Also, all six cartridge cases used several standardized case dimensions, including half a degree beta taper, and 23 degrees beta shoulder angle. This ensured that all rounds would be comparable in as many respects as possible.

Design of the Romulan round was quite straightforward. I simply indulged several of my own biases, playing off my own perceptions of different rounds and justifying them with a few pieces of solid-seeming logic. The fact that the round resembles several others that have been proposed both recently and throughout the 20th Century is essentially coincidence, but a happy one. Although the thesis of these two articles centers around criticism of the preference-driven approach, the fact that it still resulted in a round that resembles other seriously considered calibers is certainly something worth spotlighting. Even if the outcome may be much less well optimized than those possible with process-driven design, it does seem like the preference-driven method is capable of producing some kind of suitable small arms round.

Preference-driven design is capable of producing viable, if suboptimal, ammunition solutions. Left to right: .276 Pedersen, .270 British, .280/30 British, .270 Sidewinder, 7x46mm UIAC, .277 USA, 6.86x46mm Romulan.

The methodology behind the Vulcan rounds is presented with reasonable thoroughness in the first article, but it’s worth saying a little more about the project. Conspicuously, the spectrum study ended up on the .224 inch caliber. This was unintentional. When I was constructing the initial criteria, I felt it was important to have the study “bottom out” and disqualify the smallest round to show that it would not simply select for smaller and smaller rounds ad infinitum. However, this did not initially occur. In fact, the study initially included only four calibers, and it was the .224 that was intended to bottom the scale out and be disqualified. When I completed the evaluation, the .224 actually won, against my initial intentions. Because of this, I added the .204 caliber, which successfully bottomed it out. In a way, this was a happy accident, as it helps illustrate two things: First, the very fact that spectrum studies never seem to fail to surprise me helps demonstrate their value. If a process-driven design produces a surprising result, that’s a good indication that you’ve successfully decoupled the result from your own biases. Second, while it’s harder to game a spectrum study towards your own biases, it’s not impossible. I did rig the criteria to give a particular result, and although I didn’t get exactly the result I wanted, it was fairly close.

I should say up front that the metrics used in that study are not intended to be real, practical metrics, nor are the results of that study supposed to indicate an actual solution for a 600 meter round in the real world. The purpose of the Vulcan study is to illustrate the process only. The criteria used are intended to be detailed enough to give it verisimilitude, but not necessarily highly faithful representations of real physics. If such a study were conducted for real, I would expect the projectiles to be evaluated via finite element analysis and a 6 degree of freedom ballistic calculator, and those results verified by empirical results. Having said that, the showing of the .224 caliber surprises me, and this is not the first time that caliber has performed well in a spectrum study I have conducted, against my expectations. Given this, I think any future practical small arms caliber studies that exclude the .224 caliber are probably limiting their options too much. The humble .224 inch may indeed be capable of more than it is generally given credit for, especially with a low-drag bullet.

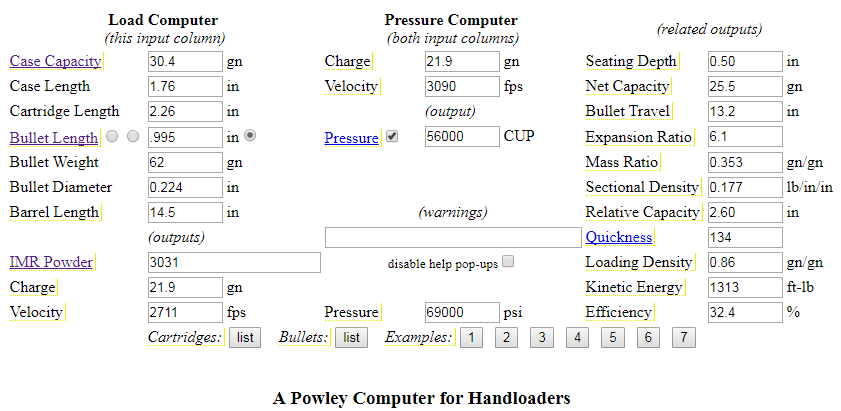

A couple other miscellaneous technical notes about the evaluation are worth sharing. The pressure limit I used for the Powley computer (56000 CUP) is based on results for M855A1 data when entered into the computer. That data is shown below, note the 56000 CUP figure needed to achieve M855A1’s muzzle velocity of 3,090 ft/s:

Those who look very closely at the data presented in the original article will note that the propellant masses given in the weight section do not agree with the charges estimated by the Powley computer for each round. That’s because Powley usually does a poor job estimating the propellant charge weight with modern propellants. Instead, I derived an estimated propellant charge by multiplying the round’s net capacity by a loading density of 102% (same as M855A1).

There was some confusion in the comments as to why I had chosen to add 250 ft/s to every candidate Vulcan round. This is something I started doing for all my evaluations about a year ago, and it’s intended to ensure the round can meet whatever requirements are needed throughout the life of the rifle’s barrel and in all climatic conditions. In the US military, a rifle barrel is considered “worn out” and ready for replacement if it produces velocities 200 ft/s below the specification, or lower. Therefore, it stands to reason that any new round ought to meet the requirements even when the barrel is nearly worn out. Likewise, any round ought to also meet the requirements in cold weather as well as other suboptimal conditions, and ideally it would do so even when both the barrel is nearly worn out and it is cold outside. Hence the 250 ft/s figure.

For lethality and penetration, I tried to choose formulas that were sophisticated enough to make it difficult to game the result (and to resemble real physics), but that were simple enough for the math to be understandable and easy for my audience to replicate themselves if they wanted to. The lethality equation was designed to reflect (albeit crudely) the actual physics of how EPR projectiles work. A key aspect I considered when creating the equation was that low energy fragmenting bodies (such as pistol projectiles) do not seem to produce optimally lethal wounds. This makes sense, as a low energy strike (e.g., 500 J) may not have enough total energy to allow each fragment to penetrate far enough into tissue to create an independent lethal wound track. Therefore, for a fragmenting projectile to have optimum lethality, it needs not only enough velocity to stress the jacket until rupture, but also enough energy to ensure the fragments carry on to create separate lethal wound tracks. The first 50 J term approximates the amount of energy needed for the projectile to penetrate the first layers of tissue, then the second term simulates jacket separation and fragmentation (with six fragments). The third term reflects the slug as it continues its penetration into the body to create a lethal wound. The fact that the lethality equation ended up being a flat 820 J for all rounds was not intentional! I had initially expected it to scale somewhat with the size of the projectile, but while working with it I realized the equations reduced to give one simple flat value across all calibers. This is an interesting observation, as it suggests that even for potentially complex work calculations for fragmenting bodies a flat energy value may be result. I am actually quite pleased with how the lethality equation ended up, because it seems to hint that a minimum energy value for effective range of a fragmenting projectile is not such an absurd idea after all.

The penetration equation is derived by one proposed by Emeric Daniau in his paper Towards a 600 m lightweight General Purpose Cartridge. Although I don’t always agree with his conclusions, the paper is still well worth reading, and it is in my opinion the single strongest case for the GPC idea published to date. Penetration and perforation dynamics are a complex thing, and this equation is probably no better than a crude estimate for that, but it is simple and descriptive and I like it anyway.

Looking back on the study, there are a few takeaways. First and foremost, given the necessary time and resources, a process-driven design study can produce substantially better optimized and more efficient products than a preference-driven study. However, process-driven methods are not magic. While – if done properly – the actual mathematics of the study will not be susceptible to bias, the writing and structuring of requirements is. It would be simple for me to create a set of requirements that gave precisely the round I wanted in the first place, all I would have to do would be to require the selection of a round that shared all its salient characteristics with what I had in mind. Because of this, process-driven design is more a tool to keep the bias of honest people away from the results, it cannot be a barrier to flagrant and determined bias introduced during the planning stages.

Also, the process-driven method cannot compensate for poor initial requirements. If what is needed is poorly understood or not well communicated, then it is possible for the results of preference-driven design to produce a more suitable end product than process-driven design, for the very same reason that process-driven design can produce more efficient and well-optimized results. Consider the evaluation from the first article. Both engineers were given a “600 meter” requirement. However, what if what was needed as not actually a 600 meter round, but a 1200 meter one? In that case, it’s likely that the 6.86mm Romulan would be the better round, simply because it larger and more powerful than it needs to be to meet the given requirements.

Finally, I would like to make a small apology regarding my use of units from different systems. One of the eccentricities of the small arms world is its extensive mixing of metric and Imperial unit systems, and this has resulted in me using either system interchangeably with little thought given to which I am using at the time. Normally, I try to either standardize on one or the other, list the figures for both, or at least use one system consistently for one kind of value (i.e., ft/s for velocity). In this case, I performed all the calculations and got well into the writeup only to find that I had a wretched mix of units and a self-imposed deadline fast approaching. So, instead of correcting the units, I simply added a short apology to the tags, and a more extended explanation here. So, if you were one of the ones that suffered a completely understandable brain aneurysm as a result of my irresponsible unit system soup, I formally apologize!

Your Privacy Choices

Your Privacy Choices