Having worn it before and knowing many who have lived because of it, body armor – specifically hard plates – have become indispensable life-saving tools for police and military. Designed specifically to defeat high velocity ballistic threats such as the AK and RPK, hard plates acre credited with 1’000s of stopped bullets. But, this protection comes at a high price. By adding armor, the wearer has decreased mobility and stamina due to the added weight and bulk.

The military has made it a large priority to reduce the combat load of the average infantryman. With full armor kits weighing up to 35 lbs including all hard plates, and accessories, there has been a huge drive to reduce the weight of armor, as shaving ounces off the weapon and ammo is becoming increasingly more difficult. The industry has been chasing this for years which led to the creation of ceramic plates which boast more effective protection and reduced weight – at the cost of increased cost and durability.

Full kit. Its heavy!

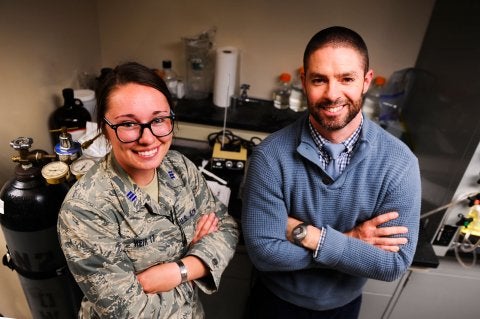

Thus, it comes as a surprise to see an Air Force officer cadet come up with potentially the next armor technological revolution. 21-year-old cade Hayley Weir posited that the combination of anti-ballistic fabric (like Kevlar) can be combined with shear-thickening fluid (like cornstarch and flour) can further decrease weight.

Combined with guidance Professor Ryan Burke and Dr. Jeff Owens, a Senior Research Chemist with the Air Force Civil Engineering Center, the three have been working tirelessly to find the right combination of fluid and film. That is until a 1/4 inch thick set stopped a 9mm and then multiple hits of .44 magnum. The material/fluid combination has the potential to protect not just troops, but tanks, aircraft, and other machines where weight is critical.

The newly graduated 2nd Lt. Wier now has a full-ride scholarship to Clemson University for a Master’s of Material Science courtesy of the Air Force to continue the patent-pending work. If the concept proves true and money is made, the young Lt. will stand to share the revenue with the Air Force.

Title photo courtesy of the Air Force Academy – Tech Sgt. Julius Delos Reyes.

Your Privacy Choices

Your Privacy Choices