Recently my local gun shop in Bloomington, IN allowed me to sit in on one of the shop’s new AR build courses being offered. I didn’t build a rifle there myself, just simply watched the course intently and took a large number of notes and photographs of what was going on. Because I wasn’t an actual student involved in the course, this won’t be an article detailing the intricacies of putting together an AR15 but is simply more a reflective perspective of what I learned. If you are interested in a rather in-depth critique of putting together an AR15, take a look at Patrick R’s writings. In addition, I know I’ll get some particular facts here wrong, so please take this as an outsider’s perspective on a very detailed aspect of the AR15, instead of a true testimony.

The history of amateur and limited home gunsmithing did not start with the mass popularity of the AR15. We certainly have accounts of American frontiersmen completing limited DIY work on their rifles from the 1800s and 1700s. Mending stocks, replacing worn parts, maybe even changing out a barrel. Our counterparts in Europe probably experienced a similar amateur experience but I don’t believe firearm ownership in Europe has ever reached the historical levels it has been in the United States (apart from Switzerland). This tradition continued into the 20th Century as we have much evidence of sportier Mausers, Springfields, and various other military small arms. But with the adoption of the M16 by the U.S. Military, and subsequent popularization in the civilian sector in the 1990s and explosion post-OIF/OEF, putting together an extremely accurate or reliable rifle has literally never been easier in the history of amateur workmanship. As a mentor of mine once mentioned, “ARs are essentially like LEGOs, snapping everything together”. To be honest, he wasn’t far off.

Note that my usage of the word amateur gunsmithing in this context is to differentiate between an actually certified gunsmith that works professionally and a gun owner that is very involved with their personal firearms.

The AR Builders Course was hosted by American Arms, a gun store in Bloomington, Indiana. The owner, Matthew Barthold, was a prior shooter on the Marine Corps Shooting Team. Matthew was involved in numerous instructing courses after his departure from the Marine Corps, then opening his own shop in Bloomington where most of his business is putting together AR15s. His partner in teaching the course was Nicholas Gillespie, a former small arms repair technician at Naval Surface Warfare Center Crane in nearby Crane, Indiana. Both of the two gentlemen had many years of experience between them in building and repairing AR15s, in a civilian and military capacity.

First off, I didn’t realize how many specialized armorers toolkits existed for the AR15 platform. Given the platform’s popularity, this should have been a given, but I was still caught off guard. A lot of the kits came from Brownell’s but this was because the shop mass-ordered the tools from the company. Numerous other industry names make and market similar or better tools. Within these tool kits were upper receiver clamp bits that allow the receiver to be placed in a vice and tightened down without actually bending or harming the upper. Then there was the punch kit that is outfitted specifically for the AR15’s different sizes of pins and other such indents. As Patrick mentioned in his article these are important for punching out parts while not flattening or otherwise damaging them. Then there was the hammer with the nylon portion on one side, and brass portion on the other, allowing a user to hit different parts by either a softer blow on the nylon side, or a harder blow on the brass.

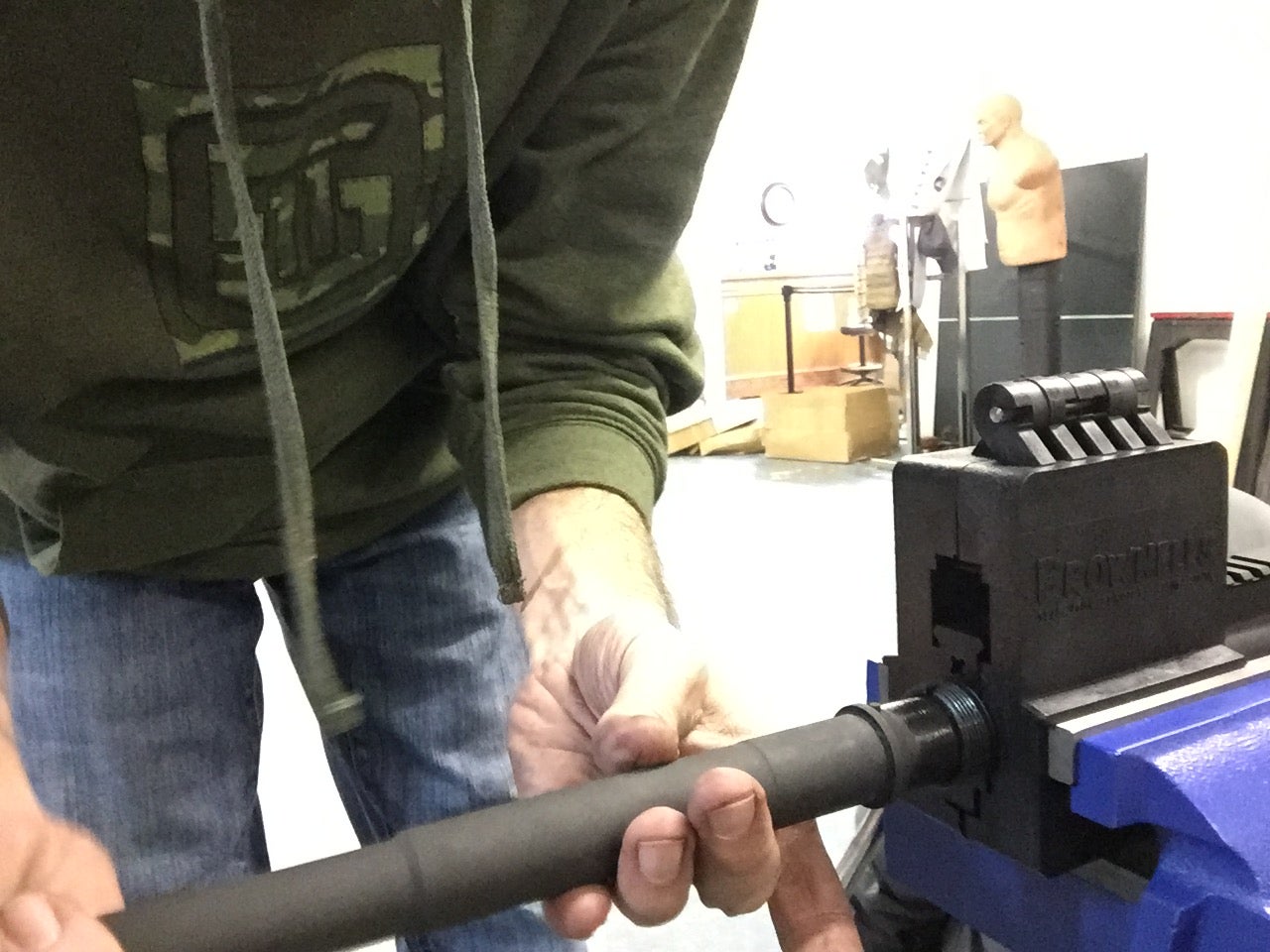

Probably the hardest portion of putting together an AR is the barrel and gas system. Granted, it is much easier to attach an AR barrel to an upper receiver than it is to press a Kalashnikov barrel into a trunnion. But even so, this is probably the largest reason why we are seeing constant improvements in barrel assemblies and even quick change barrels that can maintain a zero, even between calibers. Installing the barrel nut over a traditional barrel required the barrel installation tool, that when coupled with a torque wrench, allows an extremely tight fit between the barrel, barrel nut, and the upper receiver.

A significant portion of the class was spent on working with the handguard assemblies, most of the students using the original and standard Delta assemblies that the original M16A1-M16A4 are known for. These contraptions are much more of a problem installing than I thought they would be, involving some very tight coordination between the wide spring and the ring itself. Again, just like with the barrel nut assembly, one can easily see why a complex mechanism like this is trying to be ushered away by the industry because of just how complex and difficult they can be for people at home to work with.

The next item was the gas tube. From a shooters perspective never really dealing with a direct impingement gas tube, it never really comes into play unless of course, it becomes damaged. But actually watching the instruction and then installation of the gas tube and gas block made me have a new respect for anyone efficient enough to do these on their own multiple times over. From the barrel nut earlier being properly aligned with the tube, to measuring and making sure the tube was at the correct distance to the gas port, then finally pinning the gas tube into the block securing the block in place on the barrel. And I thought installing the front take-down pins was difficult!

Matt, the instructor of the course, was sure to point out the differences between a Mil-Spec and a commercial buffer tube along with their accompanying butt stocks.

The rest of the class covered installation of various other parts but these are relatively minor compared to working with the gas system and barrel assembly. As I’ve heard one Youtuber mention, the entire AR platform is “relatively forgiving” if you are gentle enough and have sort of an idea about what you are doing. Fitting in pins, springs, and other minor devices aren’t that difficult when you put your mind to it.

Nick explains the necessary barrel nut torque-

I hope that this is the beginning of some very in-depth knowledge about the intricacies of the AR15, which is certainly one of America’s most popular rifles in recent times.

Your Privacy Choices

Your Privacy Choices