While still waiting for the outcome of the complicated negotiations with Algeria in the early 1970s (TFB will tell you about this in tomorrow’s post), Nelmo Suzano found the time to go ahead in the design of another 9x19mm submachine gun, of which a single undesignated prototype was eventually completed. As seen in the only, low-quality, available picture shown below, the conventional blowback weapon had the 32-round magazine placed just ahead of the trigger guard, and the polymer detachable stock, pistol grip, and handguard were of a new (as compared to the Bérgom BSM/9 M1) shape. The cocking piece was a cylindrical button on top of the receiver. No written data on the gun have survived, other than indications that it weighed under 4kg, empty (still pretty heavy, though), and that the barrel was also 230mm long.

The only surviving image of the undesignated prototype of the early-1970s is just enough to show the gun’s general configuration. Note perforated handguard for barrel ventilation.

At about the same time (1973), the designer moved back to the magazine-in-grip configuration with a very interesting 9x19mm prototype designated BSM/9 M2, but that would be generally known by another nickname carved by friend Luiz Gonçalvez: the “Esqueleto” (“Skeleton”). Curiously enough, no series production for the weapon had been in Nelmo’s mind when his design turned into a firing specimen. What he really wanted was to study ways to simplify and reduce manufacturing costs, as a whole. The resulting gun, however, was – and may still be regarded as — somewhat innovative in its general layout. Let’s see.

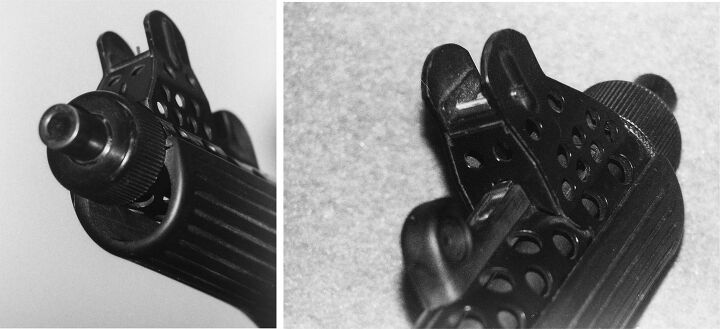

The “Skeleton’s” straight-line configuration dictated that raised sights be used.

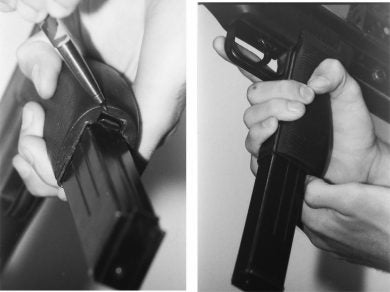

Left side view of the prototype with the 32-round magazine removed from the pistol grip.

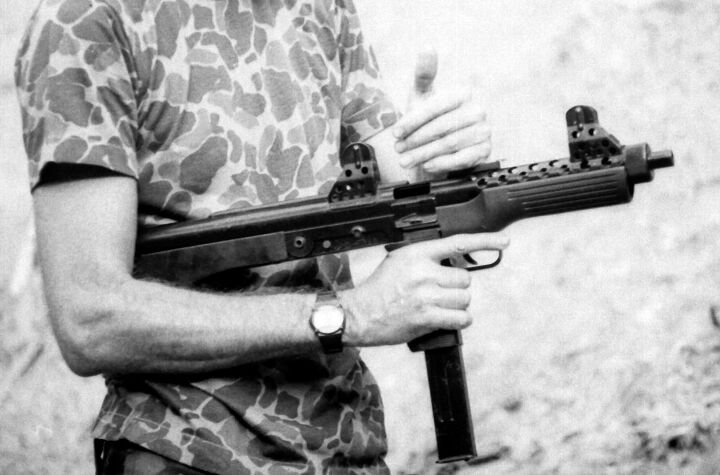

Of conventional blowback operation and firing from an open-bolt position, the BSM/9 M2 receiver was a tubular, seamless steel tube structure, the forward portion (about 1/3 length) of which had a large number of ventilation orifices around most of the 230mm barrel length. Welded to the main body was the magazine well with a slip-on polymer pistol grip, ahead of which was the trigger group and the respective guard. Just behind that was a removable metal compartment which contained the firing mechanism. A polymer handguard covered the lower portion of the ventilated area, while a slim stock of the same material extended from the rear of the firing mechanism housing to the back of the receiver, the top of the butt plate being flush with it.

The gun barrel’s axis extended directly to the top of the butt plate.

The forward end of the “Skeleton” in two different perspectives. Yup, both the front and rear sight support/protection structures were very massive, indeed.

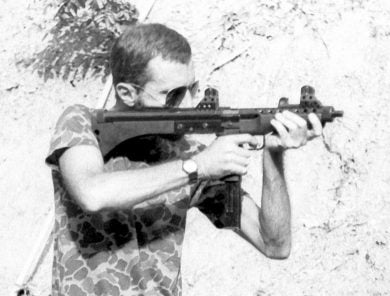

The designer’s intention when aligning the barrel with as much of the butt plate as possible was, of course, to reduce muzzle raise when firing full-auto. As a consequence, the iron sights (rear flip-type apertures; front post) had to be placed in an elevated position, which was accomplished by fitting the gun with huge perforated metal structures with equally substantial side ears. Sight radius was 220mm. The cocking handle, which did not reciprocate when the gun was fired, occupied a central position on top of the receiver, thus being ambidextrous. The fire selector was at the rear of the pistol grip, on the left side, and had the settings “S” (Segurança, Safety) to the rear, “R” (Repetição, Repetition) to the top, and “A” (Automático, Automatic) to the front. The BSM/9 M2 fired full-auto with a cyclic rate of fire of just about 550-600 rounds per minute. Weight was only 2.8kg, while overall length was 575mm.

In 1975, with no actual submachine gun production program having materialized at Bérgom S/A, Nelmo Suzano decided to leave the company. However, his friend Luiz Gonçalves still wanted to carry on, and was able to come out with some designs of his own, which I’ll bring to TFB readers’ attention in the future.

Some details of the Bérgom BSM/9 M2: (A) rear sight structure, (B) ejection port with spring-loaded cover open, (C) cocking handle, (D) front sight structure. The polymer handguard extended to the top of trigger guard.

Some disassembly stages: (A) pulling barrel out of the receiver after unscrewing its mounting nut; (B) sliding polymer handguard forward and away; (C) pulling bolt out of the receiver’s rear end after recoil spring removal.

The weapon field-stripped. The large-diameter recoil spring and shape of the bolt are evident.

Closer photo shows how the firing mechanism box fit in the gun’s body just behind the magazine housing.

The fire selector (here set in “A”, forward) was located on the left side of the firing mechanism container. Note base of the rear sight structure welded to the tubular receiver.

The magazine catch was a small (too small, in fact!) blade at the rear of the pistol grip that had to be pulled back to release the empty magazine. Eventual productions guns would, of course, have this hindrance dealt with.

The “Skeleton” being cocked for action. The weapon’s general configuration was much appreciated by those lucky enough to have fired it.

The gun’s moderate cyclic rate of fire and general compactness were some of the characteristics praised by the author.

Your Privacy Choices

Your Privacy Choices