We have covered XS Sights‘ products here on TFB several times, never failing to be impressed with the level of attention, quality, and thought that goes into each sight. Not long ago I reviewed the Big Dot sights on the Sig P320 as well as on the Glock 43; you can read my review of XS Sights Big Dot here. When their marketing manager Zack reached out and offered us a tour of their facility, after I got the go ahead from Papa Phil, quickly set up a time to make it happen since they are only down the road from me.

We started our tour in the break room, the owners at XS have been feeding their employees snacks and providing drinks since day one of the company pre-dating any of the tech companies that now follow the same model. While the XS spread isn’t as impressive as what you might find on the Google campus, keep in mind they only have about 20 employees to keep happy and full. The break room while not as impressive as the rest of the facility is a clear indication as to how highly they value their employees.

We then moved onto the room where each set of sights gets a final check and is packaged by hand to ensure every order is accurate. With several million dollars of inventory on hand, XS can process orders rather quickly.

The bin of Glock 42/43 Express rear sights was something to behold. Zack made a quick guess at the value of the bin and placed it north of $100,000. Woah!

Quite quickly I learned that many of the staff members at XS are pretty serious about their bourbon. So serious that they had a batch of their very own birthday bourbon made for the 20th anniversary. These bottles were marked for the party later that night, nothing like good food, good company, and good booze to make a good night great!

I had to pause and marvel at the sheer number of small, well machined Glock front sights being prepared to have the dot inserted by hand. I had to grab a handful to see how a couple of grand feel slipping through my fingers because why the hell not? For those of you wondering, it felt pretty awesome.

XS also has a pro shooter on staff that has a full reloading cave setup complete with TWO Dillion 1050 presses. I have to admit; I was pretty damned jealous of the setup. I can’t even seem to get my lonely 550 setup at home. Maybe one day.

They also had a whole rack of packages ready to go to firearms manufacturers that use their parts as OEM offerings. On that rack we found a box of 400 rear sights with a value of $42,000, I expect they will be using some shipping insurance on that package.

It being a family business, you might imagine that the owners have their toys tucked all over the place. We walked out of the shipping room to find a random motorcycle parked in one of the warehouses.

To keep things fun and light, the XS crew had some airsoft shotguns out in the warehouse that is used for demonstrating product and I am sure the impromptu war now and again. Zack said that they milled the plastic to fit Big Dot sights to the plastic guns because train like you fight I guess. I still find it hilarious that there is a sight mounted on an airsoft gun that costs about as much as the gun itself.

Another cool fact about the company is that when they develop a sight for a new firearm they go out and buy one to make sure that the gun they fit the sights for is no different than what the consumer has. This has the added benefit of allowing their R&D guy to reference other guns at a moment’s notice. XS has really streamlined the process of developing new sights, some of the timelines that were shared with me in regards to total development time were astounding.

The smaller safe belongs to their competition shooter; the other three safes were jam packed with every modern firearm that you could imagine.

I even ran across a Smith & Wesson M&P15-22 that they had fitted no less than three sets of sights to it. You can see that they have a set of Big Dot offset sights, a set of standard dot offsets, and flip up iron sights.

The R&D room was a bit messy, but if it works who am I to judge? As I mentioned earlier, the speed that they are able to churn out a design that is perfect is mind-numbingly fast. When Zack flipped the lights on he said: “It’s a bit messy, but we don’t ask a lot of questions.” Every time they give their engineer a task he hits it out of the park, no reason to mess with a winning model.

Poking around the R&D room, I found piled of gun parts, guns that were in various states of disassembly and more measuring tools than I knew existed. It was clear that I was in the lair of a mad scientist and should just drink in the organized chaos.

Walking back into the office section to meet the rest of the crew I spied an Instagram photo that Zack was setting up before I showed up at the XS campus. He said he had his marketing intern looking for a .50 BMG to finish the cartridge display off.

In yet another effort to keep everything in-house, they even have their own laser engraver on-site that does all the markings. So far the commitment to bring as many processes under their control while removing outside dependence was pretty impressive.

We walked over to the manufacturing side of things and found an employee sand blasting each part to remove machine and buffing marks. Each one of these pieces after blasted will be anodized or blued depending on the material.

Next stop on the tour was one of two buildings dedicated to machining the parts. Below is a bowl of standard dots that are individually milled from PVC plastic stock. Our tour guide said that these machines run 24 hours a day producing parts as fast as possible. The measuring equipment they had on hand was nothing short of impressive. Not for a second did I think that there was that much involved in making a set of sights, but I guess if you are committed to building the best sights you can, precision is the only way.

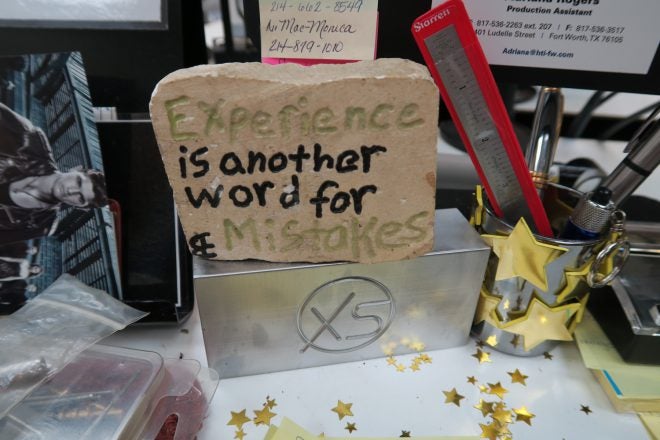

In the QC room, I ran across the coolest paperweight that an employee could have on their desk if precision is literally their job function.

When we got into the room with the big machines, I was stunned. With 17 high-end milling machines running almost non-stop XS is turning out product as fast as they are shipping it out. I was tickled to see that the milling machines were made by Brother, the printer company.

I don’t recall what sight they were making at the time, but this is right from the milling machine before any finish work. I was impressed at how great it looked and made a remark that it looked good enough to blue and slap on a pistol. I was quickly told that there were still several steps to make sure that it is good enough to be put on a pistol or even have a finish applied. They are not joking about quality.

The commitment to quality became even more apparent when I came across a bin of the high-end armorer’s blocks that had a red marking compound applied to out of spec areas. I asked what was going to come of the rejected parts and was told that they were going to be recycled. I don’t know about you, but I would be quick to snatch one up for a killer paperweight!

Ever wonder how those add on rails that screw into the top of your receiver is made? XS sources extruded metal stock that is already in the shape of the rail so that they can cut down on machine time. All they need to do is remove a bit of material to ensure the proper dimensions and cut the slots. I walked away from the metal pile thinking about all of the things I could put a rail on. The possibilities.

XS said they get metal shipments at least bi-weekly but depending on what they are making at the time it can be as often as weekly. They also said that no matter what type of metal stock they needed, it is never more than a week out thanks to the solid supply chain they have built over 20 years of operation.

As I was concluding my tour, I walked across 350 finished armorers blocks ready for finishing.

After spending some time at the XS campus, it is easy to see why they have become a fixture in the shooting community. The company was built by the current owners’ late father Ed Pastusek, after his passing, his children stepped up and continued growing the XS brand. Kellie Brunn and Jon Pastusek, co-owners of XS Sights, spent some time talking with me about the future of the company as well as talking about non-work related things like family and such. I have to say; it isn’t often that you come across a family of that caliber.

Team XS is a clear indication of the values that Ed built into the company, and his children are carrying on. Cheers to XS for 20 years in the business, I imagine with the momentum they have spun up over the last year we will will see some pretty large moves from XS in the coming year.

You can learn more about XS Sight Systems and their product line over at their website HERE.

Your Privacy Choices

Your Privacy Choices