Previously, we discussed different concepts for lightening the soldier’s load, including aluminum-, composite-cased and caseless ammunition. Today we’re going to look at the weight-reducing concept that many believe is the horse to bet on when it comes to next-generation small arms ammunition, and that is the plastic-cased telescoped ammunition concept, often referred to as cased, telescoped ammunition (CTA).

Where plastic-cased composite ammunition addresses the problem of extracting a polymer cartridge case by incorporating a metallic rim or base, the CTA concept takes a page from the playbook of caseless ammunition and asks the question: Do we really need to be pulling cartridges out of the chamber? Instead, CTA weapons are designed to push spent casings out of the front or side of the chamber, using the incoming round as both extractor and ejector. This layout requires a straight cartridge of constant cross-section, which engineers have often coupled to a telescoped layout where the projectile is buried in the round’s propellant.

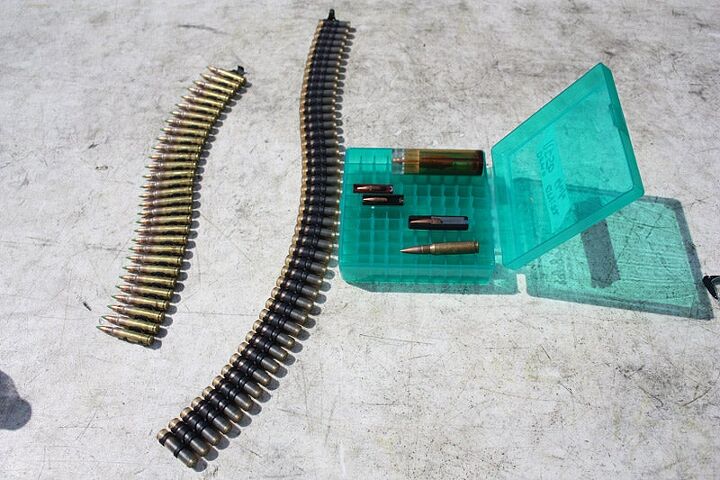

The three rounds from the title image, seen from the top. You can see how the projectiles are buried in the case. Note the petal type sabot of the 5.56mm Steyr ACR.

This concept does eliminate the problem of rim tearing with polymer ammunition, but it presents other problems. To facilitate this kind of cycle, a CTA weapon needs to have a separate chamber that moves so that the front end of the chamber is opened for ejection, but this also means that, like a revolver, the gap between the chamber and the barrel is not sealed. CTA weapons can address this in a few ways, including fixed, expandable chamber sealing devices attached to the chamber or barrel, or by using a sliding lockless design, but the problem of high pressure gas leakage remains a big challenge for CTA weapons engineers. Further, telescoping ammunition has some serious problems with gas leakage in front of the bullet, since it is difficult to keep the propellant from out-racing the projectile and burning ahead of it. In the most recent CTA ammunition configuration, this problem has been circumvented simply by not fully telescoping the round, and keeping the propellant behind the ogive of the projectile.

Some LSAT ammunition, from a 2011 shoot. Note the 7.62mm concept round, laying on the ammunition box, and that its propellant chamber does not extend past the cannelure of the bullet. Image source: kitup.military.com

However, where the concept holds the most promise is in weight reduction: the CTA ammunition developed for the US Army’s Lightweight Small Arms Technologies program have demonstrated weight reductions of 32-36%, a massive improvement versus the old brass cased paradigm. Also, since the projectile and primer are the only metallic components in CTA ammunition, a great deal of strategic material could be saved as well if CTA ammunition proves feasible.

Your Privacy Choices

Your Privacy Choices