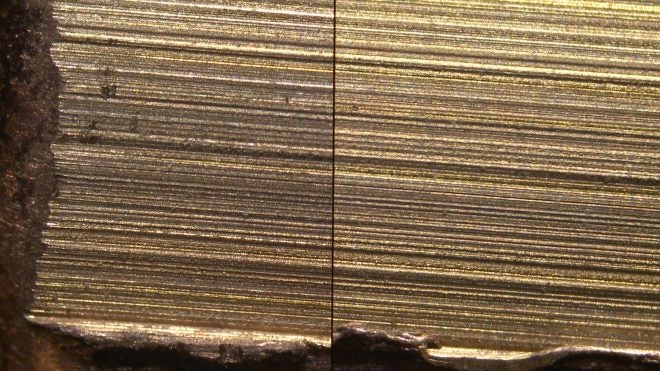

Back in what now seems like a lifetime ago, I spent a year of my life trying to find a way to match fired bullets with their respective cartridge cases. Because the ammunition manufacturing process involves pressing brass (the cartridge) overtop the softer copper alloy (the bullet jacket), I theorized that the ‘tool marks’ left on the jacket may be unique to each bullet – even after they are fired through a barrel. Using molded casts from the inside of spent casings and comparing them to their respective bullets that had been fired into a water trap, I used a comparison microscope to attempt to identify any possible matching impression and tool markings. Why was I going off on this scientific journey? In part because of Polygonal Barrel Rifling.

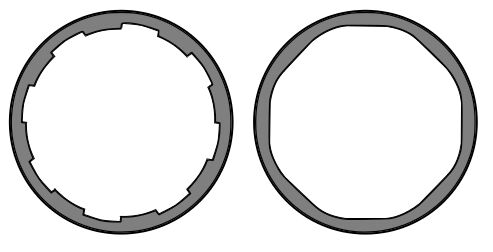

In traditional rifling, ‘tools’ such as buttons or broaching bits are used to either press or cut grooves in the bore giving the barrel a defined rate of twist. In polygonal-rifled barrels, the barrel (and hence the bore) is cold hammer forged (or otherwise twisted) creating swells or mounds, also giving the bore a defined rate of twist. That is a very oversimplified view of both types of rifling, but the one important difference is that a tool creates traditional rifling – but that’s not the case in polygonal rifling.

Traditional rifling (left) and polygonal rifling.

Firearms identification, a broad term used in forensic science to describe the study of what is usually incorrectly referred to as “ballistics”, includes the study of the tool marks left on a bullet from the lands and grooves as it passes down the barrel. Because polygonal-rifled barrels don’t use a tool to make traditional lands and grooves, identifying bullets fired from a polygonal-rifled barrel that was used in a crime is challenging.

Using a comparison microscope to compare two bullets with tool marks.

Bullet fired through raditional rifling (a) and polygonal rifling (b). Credit: Bev Fitchett

On the flip side, the breech face and firing pin leave their own set of unique tool marks on cartridge cases that forensic scientists can use to identify which gun fired a specific cartridge. For example, if you take three pistols and fire ten rounds a piece, a good crime lab analyst can match up all 30 casings back to each respective gun. Not to mention the extractor and ejector tool marks left on casings as well.

Breech face tool marks.

Now, putting this all together, if a criminal uses a polygonal-rifled pistol in a murder, the forensic scientist working the firearm identification part of the case is going to have the difficult task of positively matching the gun that fired that bullet – remember, no tool marks. However, if my theory panned out, the bullet could be matched with the casing which could then be matched backed to the gun. Bingo.

Not so much. Long story short, although I was able to identify some matches, the tool marks made on bullets by cartridge cases during manufacturing was unreliable as a scientific process. Meaning that it wouldn’t hold up in court.

For shooters, polygonal rifling has distinct advantages over its swaged brothers. For one, the bores create a tighter gas seal leading to higher muzzle velocities, but less lead deposits/cleaning and extended barrel life are also considerations. And like everything in the firearms industry, there is great debate between which is better, traditional or polygonal rifling for precision shooting. As long as it doesn’t have a manual safety, I don’t really care. (Sorry, I couldn’t resist.)

Polygonal Rifling. Forensic Science. Firearms Identification. And that’s The More You Know.

Your Privacy Choices

Your Privacy Choices