The Barrett “Light Fifty” is probably one of the most iconic firearms in the world, along with the Kalashnikov, Desert Eagle, and the M16. The M82/M82A1/M107/M107A1 is unique in that it occupies a spot that very few other modern designs have even been able to compete with. That of a .50 BMG anti material rifle, the brainchild of a man who simply wanted to build a .50 caliber rifle because he couldn’t have an M2 machine gun. Indeed, when Ronnie Barrett, a professional photographer first proposed the idea to a fellow in the gun industry, all he got was, “If this was a viable idea, it would have been invented already”. Ronnie said no, and went on to create a stamped sheet metal semi automatic rifle that changed the way much of the free world’s armies work at long range precision shooting.

Christopher Barrett, the current company President left, and Ronnie Barrett, his father, right, with a prototype Barrett 240 Light Weight medium machine gun.

While raising a family, Ronnie dived head first into an industry he had absolutely no experience with, especially not any firearms or mechanical expertise on his side. But nonetheless, he started putting together rifles in his gravel floored garage in Murfreesboro, Tennessee, later upgrading to a small building he leased on Manchester Highway. The building used to be a Bluebird school bus repair facility, and it was in here that the majority of the M82s in the 1990s were built at. The company grew until he bought a small building all for his own. This was later expanded with a larger addition, differentiating from the older one as “Up the hill”, the older one being “Down the hill”. The “Hill” is simply a ramp that connects the two buildings in between, as it is affectionately known among the Barrett employees of today. This newer building is much larger, and has a higher ceiling, for the better ability of the company to employ massive CNC machines where the various rifle parts are machined and put together.

Although Ronnie is taking a step back to let the next generation of designers and leaders take on the company, he is still very much active in the day to day activities of design work. Here examining the 240 Light Weight.

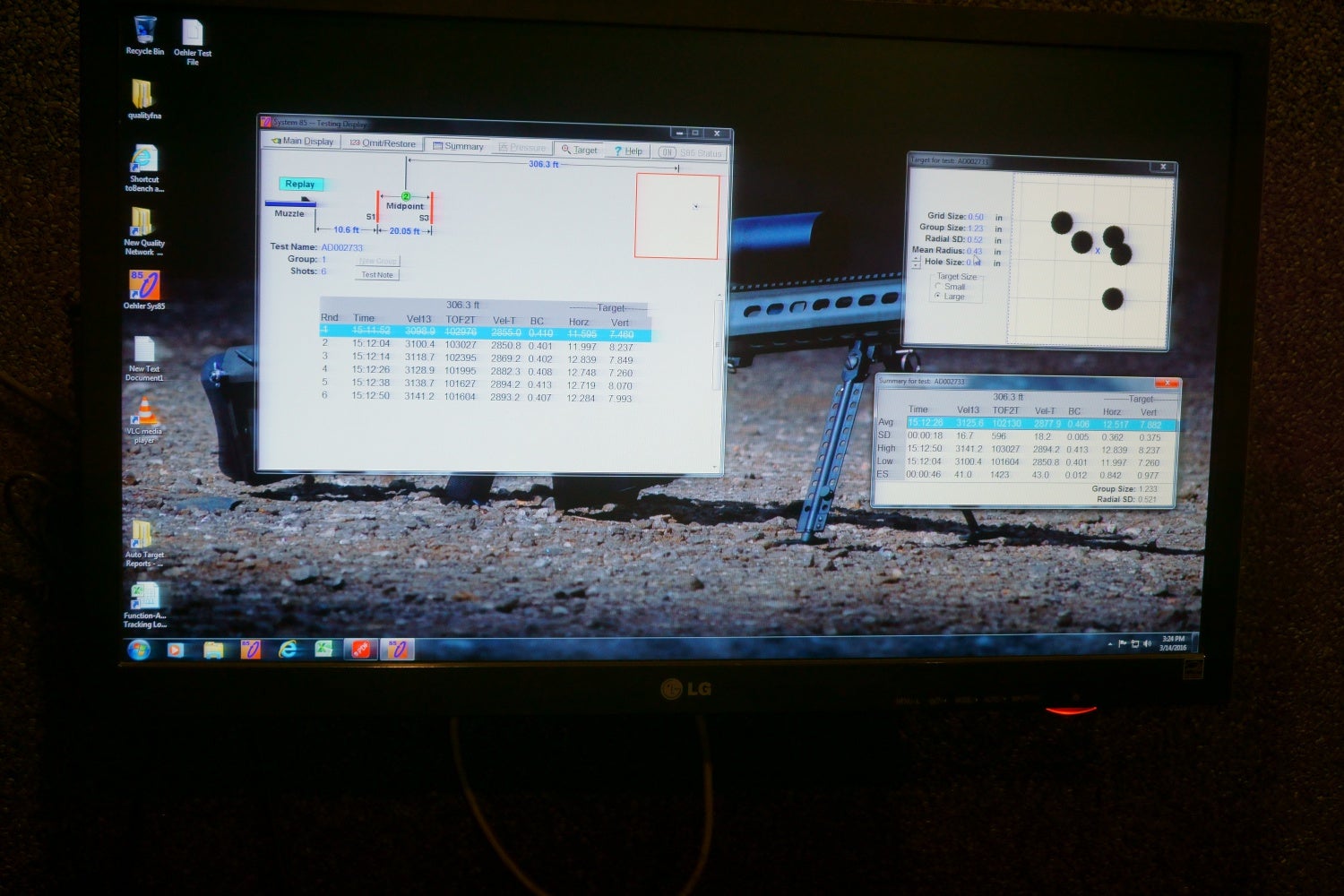

Somewhat between these two buildings is a 100 meter test fire range where every single firearm that leaves the company grounds for sales is proofed with two high pressure rounds, in addition to being fired for accuracy and function checked. Barrett has an acoustic shot group system set up, so employees don’t have to be going downrange and attach paper targets to a display anymore. The entire system is automatic, so a test shooter can see their groups on screen and have them measured extremely accurately, even measuring the velocity of every single round as it goes downrange.

This is a pneumonic air compressor device fixture that is used to blow air at an MRADs trigger, thus remotely firing the rifle with proof rounds, while the tester can stay back behind safety.

The company has come along way from the early garage days in Ronnie Barrett’s house in Murfreesboro. Due to recent changes in manufacturing and efficiency over the past decade, the company performs with the precision of a well run machine. Each step of the manufacturing process is very exact, and every single part or group of small parts that is produced has a flow sheet that is attached to it, with employees verifying and tracking the part production at each step of the way. After every major bit of manufacturing, the parts are sent back to quality control, where the QC employees run measurements and checks on it to ensure it is up to standard, before sending it back into the next process, where it is then sent back to quality after enhancing it more. This process continues until the pieces are assembled as a rifle. If at any step in the process a piece is rejected, or isn’t up to standards, it is either sent back a step, or rejected. I was amazed at just how often parts were checked for consistency throughout this whole process as I toured the plant.

Quality Control room, Every piece the company makes comes here several times during the manufacturing process to make sure everything is up to standard. This table has to be calibrated once a year for the angles it is at, because of the important of measuring critical dimensions of parts on it.

Although Barrett doesn’t rifle their barrels from raw stock, they do complete everything else about them. On the left is a REC7 barrel as it arrives from a barrel manufacturer, on the right is the finished product, with the company milling out the profile, drilling the gas port, cutting the chamber, and crowning/threading the muzzle.

M107 pintle mounts so shooters have the ability to mount them to existing machine gun or helicopter mounts.

This part of the factory is where all the AR platform rifles are assembled, the REC7 direct impingement and piston operated rifles.

But more important than any machines in the building, are the people that run them. Chris Barrett calls this the Barrett “DNA” of the company, the people on the floor making a difference when it comes to manufacturing. All too often I was introduced to workers who had been at the company for a decade, if not longer. Chris Vasser, one of the top designers at the company has been with the company since its inception. Barrett also strives hard to take care of the people that make the magic happening, offering employees to purchase one Barrett firearm per year, at less than dealer pricing. After working at the company for long periods of time, the company offers paid vacations for the work put in by the employees. I asked one of the men running a CNC machine milling out gas blocks for the REC7, what keeps him focused on his work and he had this to say,”What keeps me going is that I know that the rifles we are making here, are being used by good people around the world, that might find themselves in terrible situations, soldiers downrange. Those people have to know, beyond a shadow of a doubt, that when they pull that trigger on a Barrett firearm, that rifle is going to go bang, every time. Because if it doesn’t, it could mean their lives are on the line”. In fact, there is actually an old tale from one of the companies oldest employees where some snipers deployed downrange called the company while at their patrol base in Iraq, and asked how to fix a part that they had bent out of shape in their Barrett rifle. After a brief phone call, and one of the Barrett designers telling them what needed to happen, the rifle was fixed, and back in action.

240 LW bolts, having just been taken out of the parkerizing tank. Underneath them is the flow sheet that tells employees where they need to go next, who signed off on their process, who signed off on quality control, etc…

Preparing 240 Light Weight receivers for parkerizing. The black Barrett shirt is more or less the official company uniform.

These two gentlemen are responsible for actually turning all the completed parts into a complete rifle. If you have a large caliber Barrett rifle, chances are these two guys have completed the final assembly of it.

Along with the people, comes the life cycle of their rifles. The company has a full warranty and repair department that focuses on nothing but getting rifles back up and running, whether it be a civilian REC7, or a military M107 in active duty service. Along with that, the company offers training classes to do with long range precision shooting, and armorers courses both in house and off site. In fact, the company has an entire classroom dedicated to it, where students can bring their own Barrett rifle in, or they can use a company supplied rifle.

The ready room for all the finished rifles. Cardboard boxes on the walls are for REC7s, while the larger rifles are stacked in movable racks, arranged by type, and waiting to be put into transport boxes.

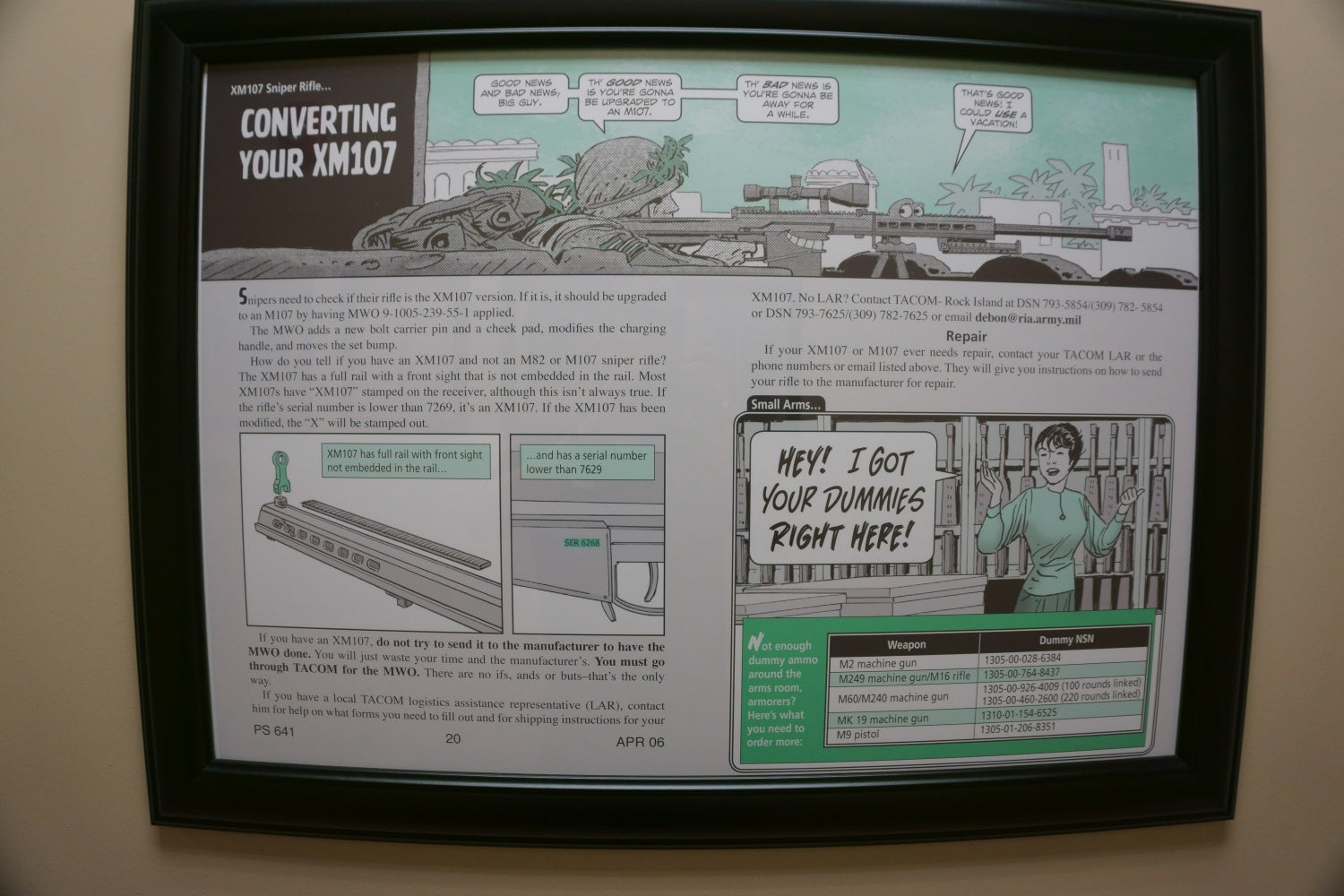

Currently the U.S. Military is only using the M107, and not the A1 version, which has several enhancements done to it. But posters like this are framed all over the factory walls, congratulations and praise coming from military and LE units all over the world.

However, despite Barretts worldwide success story, the company is not one to be sitting back and letting its products sell themselves. Today, the company is churning out more rifles than it ever has, at any point in its history, due to changes in the clocklike efficiency of the daily operations. More importantly the company is working on newer designs and introducing many of these designs to the market, broadening its product base. Everything from suppressors, to the diverse direct impingement and piston operated REC7 line, the MRAD line, and more recently the Barrett 7.62x51mm 240 Light Weight (LW) and 240 Light Weight Short (LWS) medium machine guns. Would you be surprised if I told you Barrett is licensing a line of high end over and under, Italian made hunting shotguns? Well I certainly was, and sure enough, go ahead and read about the Barrett Sovereign line of shotguns. All this is to prove the point that the company isn’t sitting back on its success, instead it is pushing forward with new ideas, new design concepts, and new products in both the Military/LE world, and civilian world.

Some of the new features that the company has done to the 240 Light Weight, and 240 Light Weight Short (in tan). These machine guns have already been sold to several militaries in the world.

An AM suppressor ready for shipment, this one is in .30 caliber. They also have the QDL suppressor for the .50 caliber M107A1

This factory tour is one article out of five that will be coming out on TFB. Next up will be about the M82A1/M107 manufacturing process, an in-depth look at the 240 LW, shooting the REC7 series, and shooting the MRAD.

Special thanks to Jordan Progar, Christopher Barrett, and the entire Barrett team for making this article a reality.

Your Privacy Choices

Your Privacy Choices