This is the third article about the Russian AKS74U submachine gun. The first one was about the etymology of the word “Krinkov”, and the second one was about how the AKS74U came to fruition, and its actual use in Soviet service. Some readers have said that they would like to have some of the many variants and clones of the AKSU written about. In time, I might churn one out about them, but for the time being I’m focusing on the original Russian submachine gun (or in this case the NFA SBR legal in the United States), and nothing else. The reason being, is that from a historians point of view, I think it is absolutely essential to get back to the roots of where we are now, to understand how we got there. In this case, it is the phenomena of a short barreled Kalashnikov platform, and the roots of such, were the Russian AKS74U. Today that has branched into all sorts of variants in Europe, from the Bulgarian late AKSU copies, to the Yogo M92s, and in America with a number of companies specializing in short barrel AKs, from Krebs Custom, Rifle Dynamics, and Kalshnicohn. But for the purposes on this article, I’ll be focusing on reconstructing a Russian AKSU, and the inherit challenges a project will have.

A note on year differences

To begin with, the statement of a “Tula” parts kit is somewhat misleading, because essentially the overwhelming majority of Russian AKSUs were built at the Tula plant in Russia. The Izhevsk plant was really only used from initial production to about 1981 where production was shifted to Tula. This is because the Izhevsk AKSUs were mostly prototype builds, and initial manufacture. Once everything got set in place for full fledged manufacture, the tooling was taken up in Tula and nothing further was made at Izhevsk. Another reason for this is that Izesk was where the overwhelming majority of AK74 service rifles were produced, so that plant already had their hands full making the standard issue service rifle for the Soviet Army. Izhevsk parts kits are extremely rare in the United States, I’ve never even seen or heard of one for sale over the internet. With that being said, for some reason a majority of the Tula kits in the United States are from 1986, or at least those represented on the internet.

The Tula production builds break into two groups, pre 1985/86 and post 1985/6. This is because there was a change in handguard production in late 1985 at the Tula plant. The change is one of the easiest ways to quickly identify the year of an AKSU, even in black and white pictures. Essentially in late 1985, the ventilation holes in the handguard were taken away, to ease manufacture. In addition by this point it was realized that the gun, being more or less a PDW, wasn’t being fired nearly enough in combat to really take advantage of the cooling system. That being said, if you’re interested in a truly early parts build, look for a parts kit that has these ventilation holes in the handguards. Although this is the the biggest visual difference between year models, there are a number of minute differences that if you are a meticulous collector, you can get into. AK Forums has an absolutely excellent thread on how to spot these differences, literally from each year of production. They list it down to the types of corners on the stock, and down to the cuts in the wood. So by all means, if you really want to get down and dirty with a build, do some research on that site, and you’ll probably get more than enough information as to what exactly you have, or what exactly you should be making to replicate a certain year of production on a build.

Parts Kits

Are pretty much gold these days. Unless the market finds another way to import parts kits in from Russia, or find a stash of them in some other distant part of the world, we’re somewhat out of luck when it comes to acquiring these at a decent price. They used to be in the sub thousand dollar range, complete with the original Russian barrel. Nowadays, most kits won’t have the barrel, and they’ll be over a thousand dollars. A prime example is this parts kit for sale by Allied War Machine, going for $1,600, and doesn’t even include a barrel. And by the way, that company only has 9 of them as this article is written. So essentially you have two options today, shell out the cash for twice what the kit was worth even 5 years ago, or wait, for a new source, which is probably not going to happen in our life times. Right now the best best is probably to scour the forums for parts kits, posting ads all over the place for one. But you now you can see why alot of builders are opting for Bulgarian copies instead of the Tula kits, because the price is much better, and there are alot more out there.

Barrels

If you thought parts kits are hard to come by, think again about barrels! Essentially most builders will have four options when it comes to AKSU barrels: Original Russian barrels, Bulgarian barrels, Blue Jack barrels, or a privately made one. The important thing to note about AKSU barrels, is that they have a different twist rate than AK74 barrels. So you really can’t chop a 74 barrel down to SBR length, and expect it work with an AKSU build, because it won’t. The twist rates are completely different, because the length of barrels are completely different from the get go! Some guys have tried this with limited success, but bear in mind, this is really hard to do. In addition, the AKSU was designed with this tighter twist from the beginning, because of this problem of the shorter barrel.

Original Russian barrels can usually be only found with the associated parts kit that it would have been imported into the United States with. Outside of parts kits, they can be extremely difficult to track down, in addition to not bursting the bank getting one because of how rare they are outside of their kits.

Thus, a number of AKSU builders like to go for the Bulgarian barrels because they are a little more widespread than the Russian ones, and they fit the same dimensions due to Bulgaria copying the post 1985 model AKSUs for their identical version of the AKSU. Regardless, these barrels are still quite expensive today, compared to what they were in the years past.

However, there is a local American gunsmith who goes by the name of “Blue Jack”. His shop, or the guy himself is in New Martinsville, West Virginia. He is the only maker of successful American made 5.45x39mm 8.5 inch barrels today. He started researching and making barrels about eight or so years ago, and just about stopped in 2013 or so. There is no public point of contact for him, no number, or email that is on a website somewhere. He makes a few posts on a number of AK forums, waits for orders to come in, and ships off his barrels to his customers. he makes about 100 barrels per order, and these are labeled by a numerical designation. Thus you have BlueJack V1.00, and V1.5. Each change in the numerical value has a better design tweak, or something that he has improved about the manufacturing process. Apparently he was able to get ahold of the original Russian barrel specifications and this is why his barrels work so well. This goes all the way up until about 3 or 4, when he decided to stop making the barrels for what appears to be for good.Since then, his barrels have gone up in price, to the point of paying up to $500 for a virgin Blue Jack barrel. This from paying around $200-300 per barrel about five years ago. I’ve tried to get in touch with him over his barrels, but it looks like he doesn’t want people pestering him unless they are going to be buying from him. Personally, I’ve got a Blue Jack barrel on the historical build that was put together by Kalashnicohn in Pheonix, Az.

The fourth and final option is to find a local barrel maker, or a company/smith who has dambled in AKSU barrels beforehand. Some of these tend to actually work out, because they know what they are doing, while others fail miserably, attempting to cut down a full length 74 barrel and trying to make it work with the shorter length.

A barrel section wouldn’t be complete without a trunnion section as well. Any standard AK74 5.45x39mm trunnion will work with a build. That is unless the trunnion that came with the parts kit wasn’t cut in half already. If that isn’t the case, just go with the actual trunnion that came in the kit.

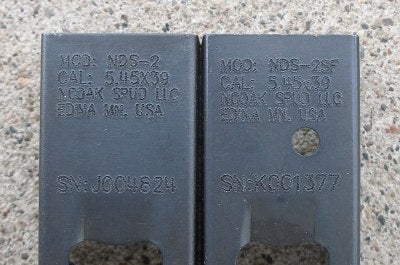

Receivers

Expensive this, expensive that, fortunately one of the only major components that won’t break the bank will be your receiver. Standard virgin AK receivers made in the U.S. without the third pin hole for the automatic disconnector, tend to go from $80-200, depending on the different features, material, design, etc… But most of these will be around $100. Here you aren’t limited in your range of options as you are with the barrels and parts kits. As long as the receiver is made right, and is from a reputable company, you won’t be having any issues with the construction or reliability of the receiver that you pick. NoDak Spud LLC is a good starting choice, they make a wide variety of AK receivers that you can pick from. But specifically for an AKSU, you need their AK74 receiver, with a folding stock latch, and folding stock compatible rear end trunnion holes. To be exact, this is the one that I ordered, “Model NDS-2SF with plate“. There are several small companies out there that specialize in really bringing them to reproduction life, putting in details that will make your rifle more authentic, such as Cyrillic selector markings and a faux third pin hole that makes it look like it has a pin for the disconnector, but there really isn’t anything inside that hole. Receivers are also important because this is the actual serialized portion of the rifle. Most of these companies will stamp the serial number just ahead of the magazine, where it isn’t visible from the sides. The great part about this technique is that the original Russian serial number is still visible on the trunnion, and the bolt. Russian serial numbers don’t have any legal meaning here in the United States because the ATF only sees the receiver as the serial number compliant firearm part. This is excellent because from the outside, we can get the rifle looking as authentic as possible, without having to sacrifice losing the original serial number.

The important thing to realize about the receiver is that this is the firearm. It requires shipment to your FFL as a serialized item, whether or not anything has been built on it as of yet. Of course you could get the raw sheet metal cut outs, and work from there, but very few of us have the machinery to complete this in our garages.

Accessories

Having the original accessories to a collectable firearm add to its value later down the line, and it really makes owning it that much more enjoyable if you really partake in the history aspect of it. The AKSU has a number of accessories that are unique to it, specifically the sling and airborne drop case. The sling is different from the standard AK74 slings that were issued, in that the AKSU sling is a tad bit narrower than the AK74 version. The drop case made for the AKSU is more of a simple protective transport case, rather than a heavy duty design that could be strapped to a paratrooper jumping out of a plane. It is affixed by two strings with the stock folded, and a magazine placed into a pouch underneath the gun. It has two slots at either end of the case, for the sling to poke through and the entire piece be shoulder carried. Slings and carry cases are both readily available online through Ebay or Gunbroker for relatively reasonable prices. Magazine pouches are the standard AK74 olive drab 3 cell pouches, with an oil can cell as well. These aren’t too expensive either. Special cleaning kits were also made for the AKSU, and if you go into that forum I listed up above, they actually go into the years of manufacture for these cleaning kits.

For magazines, the majority of Russian troops used the bakelite Tula star marked magazines as the rifle was only made at Tula during the serious production runs. Arrow within a triangle marked Izhevsk magazines work perfectly fine, but if you are going for authenticity, I’d recommend searching for Tula magazines. Finding either type of original Russian magazine isn’t difficult, but it can be costly, starting prices are usually $50 and just go up from there in price. 45 round RPK magazines are also an excellent touch if you can find some at a good price. If you look at my earlier post about actual usage of the AKSU, you’ll see that a number of pictures of Soviet troops in Afghanistan got ahold of 45 round RPK magazines, or taped 30 rounders together. This was because although the rifle really couldn’t perform past 100 or so meters, its effect at close range, on full auto was absolutely devastating if used correctly from a vehicle.

Legal challenges, 922(r) compliant parts

To start off with, I’m certainly no expert when it comes to the 922(r) compliant parts rule, so I’m going to give TAPCOs explanation of the rule, in its entirety here-

Title 18 Chapter 44 Section 922(r) of the United States Code, defined further by Title 27 Part 478.39 of the Code of Federal Regulation (CFR), ambiguously restricts semiautomatic rifles and shotguns to no more 10 imported parts from a list of 20 parts.

This one section containing a few paragraphs creates far too much confusion. This short synopsis is an attempt to clarify, in simple terms, the 922r regulation. Hopefully this can offer a simple way to evaluate your rifle or shotgun in order to easily assess what you need to do to ensure your rifle is compliant.

When considering compliance the big thing to keep in mind is the magic number 10! The infinite wisdom of the federal government has decided that it is unlawful for your semi-auto rifle or shotgun to have more than 10 imported parts from their select list of 20 parts. Many describe this in terms of U.S. parts count, but in reality this should be the foreign parts count. Now this is where the debate occurs.

27 C.F.R. 478.39 lists 20 parts:

(1) Frames, receivers, receiver castings, forgings or stampings

(2) Barrels

(3) Barrel extensions

(4) Mounting blocks (trunions)

(5) Muzzle attachments

(6) Bolts

(7) Bolt carriers

(8) Operating rods

(9) Gas pistons

(10) Trigger housings

(11) Triggers

(12) Hammers

(13) Sears

(14) Disconnectors

(15) Butt stocks

(16) Pistol grips

(17) Forearms, hand guards

(18) Magazine bodies

(19) Followers

(20) Floorplates

Of these twenty parts, the laws states that you can have NO MORE THAN 10 imported parts on your semi-automatic rifle or shotgun. These twenty parts are meant to cover all platforms, and as you know all platforms are not the same. Without getting into specific platforms, starting out you know that you will not have to change more than 10 parts to ensure your rifle is compliant.

There are arguments like “the SKS does not have a pistol grip so that is not a compliance part for the SKS”. If your SKS has no pistol grip and you choose not to add one, then this is correct. BUT, if you buy an aftermarket stock that contains a pistol grip, you have just added a part that is in the parts list and it will count against you if it is not U.S. made. It does not matter if the platform does not have a covered part normally, it matters what you have on your rifle or shotgun.

A suggestion to ensure compliance and to understand how 922r applies to you is to:

(1) Find out all of the possible parts that apply to YOUR rifle. Below you will find a list of the parts applicable to the FAL, AK, SKS and SAIGA.

(2) Lay your rifle down and start counting. (Unloaded and safe of course)

(3) Go down the list of parts that are applicable to your rifle and find each part on your rifle. Make a check for each item you have that is a foreign part.

(4) When you get to the end, add up all the parts that you have that are foreign. If your foreign parts count adds up to ten or less then you are compliant. If not, you need to start replacing some of those foreign parts until you get down to ten or less foreign parts.

On my AKSU, the receiver, barrel, and trigger/hammer group are all American made, so I’m at the magic number ten number. If you want to use an American made magazine, this would subtract one of these parts and you’d be able to add a Russian trigger group, or barrel for example.

With the legalities of the AKSU being an SBR, the important thing to realize is that you can purchase every single part used in a build without going through the Form 4 yet. However you cannot keep the barrel in the same physical location as the receiver. Because if the barrel especially is in the vicinity of the rest of the build, the ATF looks at this as an intent to build, and thus constitutes an illegal build. Keep the two separated, at a friends house, or in a safety deposit box. Once you get the tax stamp, keeping the two together is not a problem at all. Personally, I opted for the traditional mail in method instead of the Trust, just because I didn’t want to get too complicated with anything. It worked perfectly fine for me, as I’m not too worried about where the gun goes when I pass, and I don’t worry about letting other people take it to the range or not. Anyways, the point I’m trying to make is that if you are interested in this project, nothing should stop you from getting all the parts now while they might be at a manageable price, instead of waiting for when you get your tax stamp, and the prices might have jumped to unreachable levels.

Once the Form 1 is in, mail/take it to your builder, or you can begin work on it. Bare in mind that you do not have to give the builder the original Form 1, just a photocopy of it. If you decide to go through with a builder, pick a quality gunsmith/builder, who specializes in AKs. Big emphasis on AK knowledge. There is a plethora of gunsmiths out there who are great with firearms, but don’t have the required knowledge to do with AKs, which can be a whole other beast when it comes to putting a build together. Unlike ARs, AKs aren’t put together like legos. Trunnions require riveting, receiver sheets require bending, rear stock trunnions also require riveting. The barrels require being pressed into the trunnion. some of this requires special machinery, and it certainly requires knowledge and experience to produce a well finished product.

I went with Kalashnicohn out of Pheonix, Arizona. The guy knows a thing or two about putting AKs together, and did an excellent job on mine, even refinishing the wood, and metal. Some other well known AK builders that have experience with AKSU reproductions are Piece of History Firearms in Tucson, AZ and Rifle Dynamics in Las Vegas, NV. Although Rifle Dynamics is much more well known for their more modern builds and designs, they also do excellent work on historical reproductions. Due to demand, Rifle Dynamics has a very long wait time to complete builds, but you are getting a quality product when you order from them. Jerimiah Cohn from Kalashnicohn made an outstanding piece, and I would certainly pick his company again if I were to go through with a build. He had it done in a matter of weeks, and put in every detail that I wanted to have done to the rifle, to include the Cyrillic letters for the Safe, Auto(non-functioning), and Semi markings.

My biggest piece of advice when going with a shop completing the build for you, is to ONLY deliver payment AFTER the build is complete. I learned this the excruciatingly hard way, while dealing with a gunsmith on the East Coast. Essentially I paid him for the work before he started work on it. This led to him dragging on and on with the build, eventually not even completing it, and sending it back to still unbuilt. The lesson learned here is that when you take away the incentive for a person, any person to complete a project, then the project becomes less of a priority for them overall. The other important part here, that I mentioned earlier, is never send your original Form 1 to the builder. Legally, they don’t need it.

Anyways, I hope this article has been informative, and hopefully useful, if not simply entertaining!

Your Privacy Choices

Your Privacy Choices