After our tour of the Ilion plant we all headed to Huntsville Alabama to tour the new facility. Currently Remington is making all of the 1911s there as well as the Bushmaster line and the new RM 380 micro pistol. Any and all handguns will be made there in the future. Other guns are in the works to be made in Huntsville and will be announced later.

A lot of the space both office and other floor space is currently not being used but as with any new facility construction and installation of equipment continues pretty much non stop. As the facility works towards completion the number of employees continues to grow as well.

I should also mention AAC products are also currently being made in Huntsville.

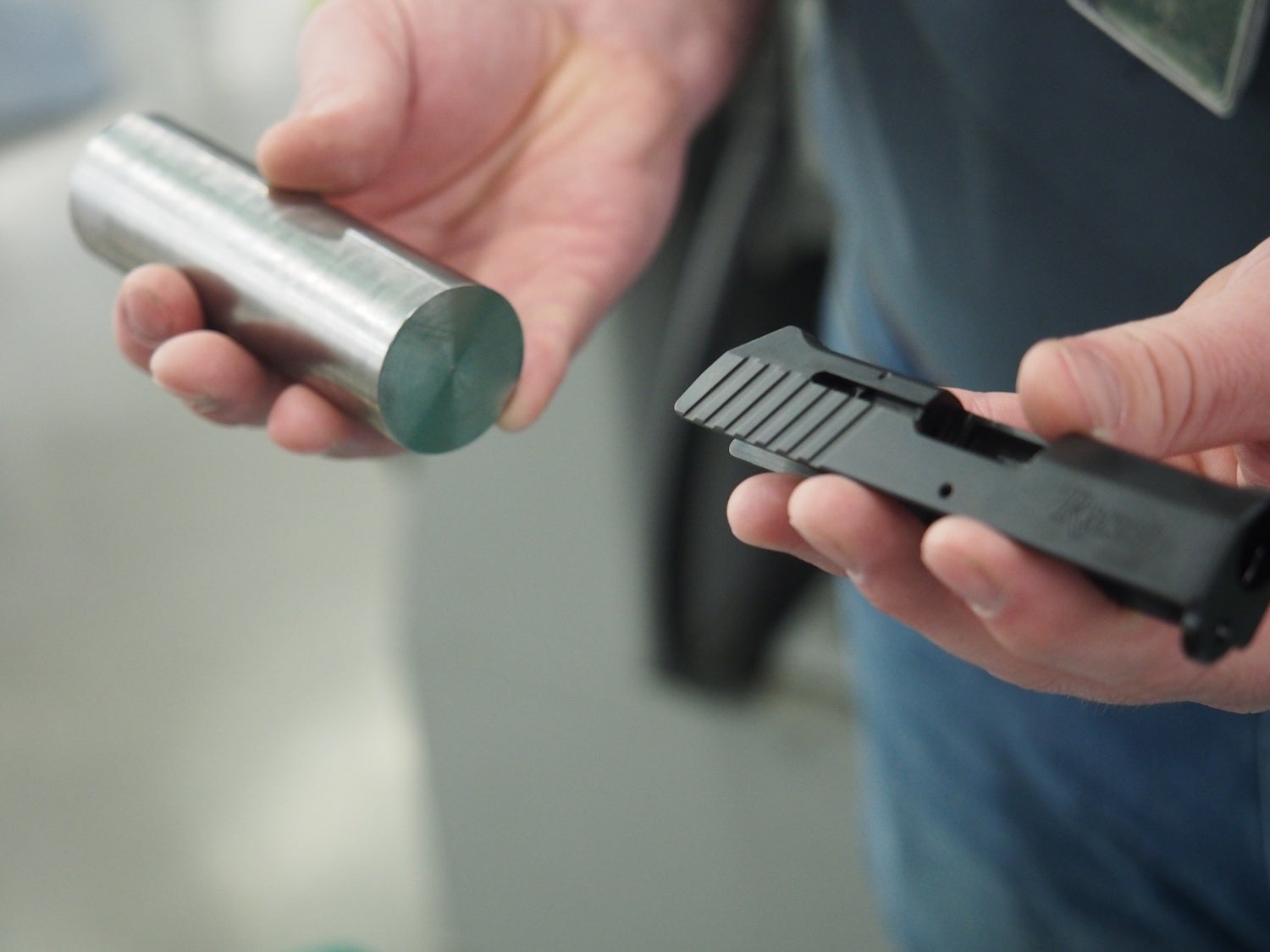

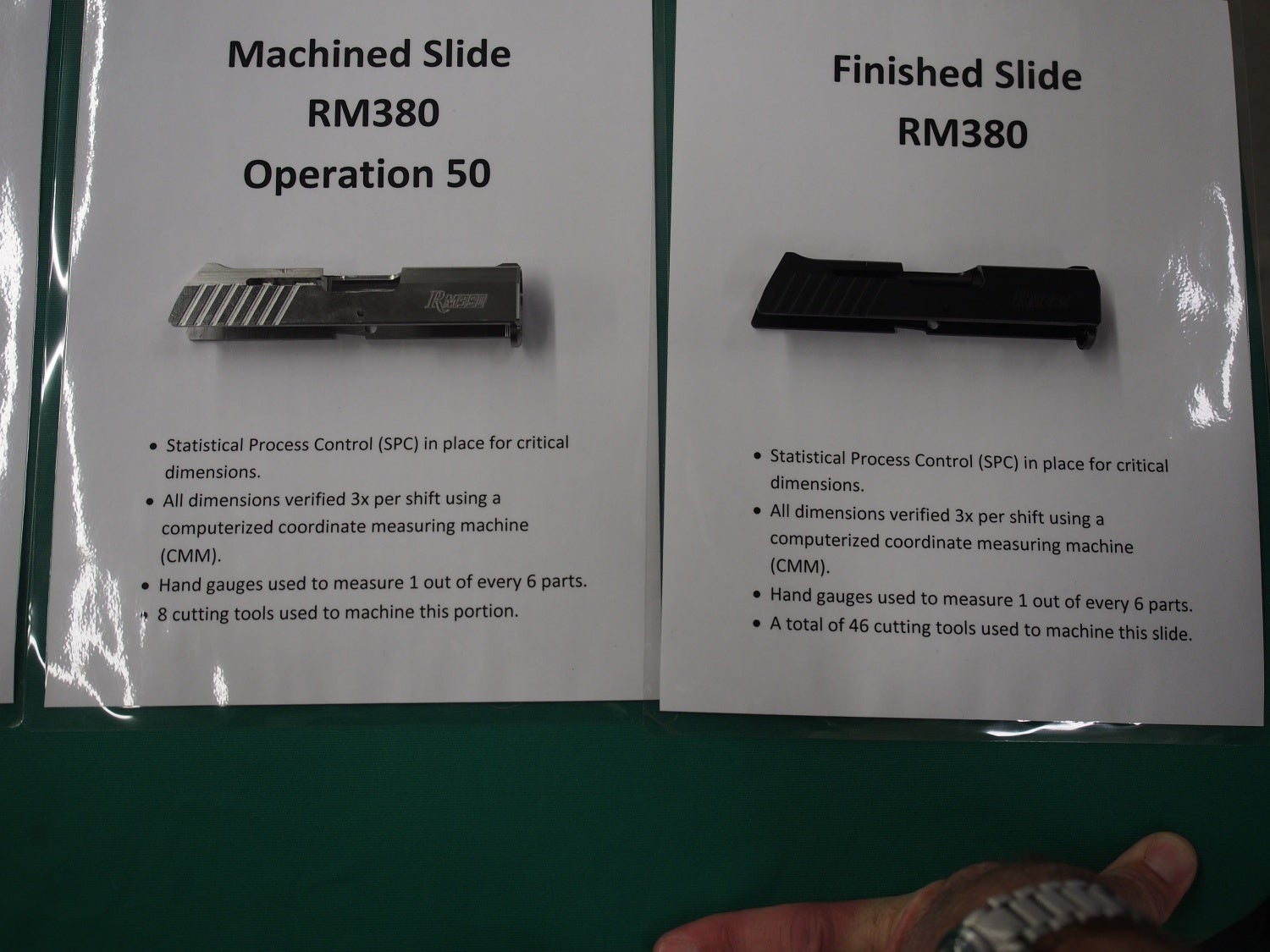

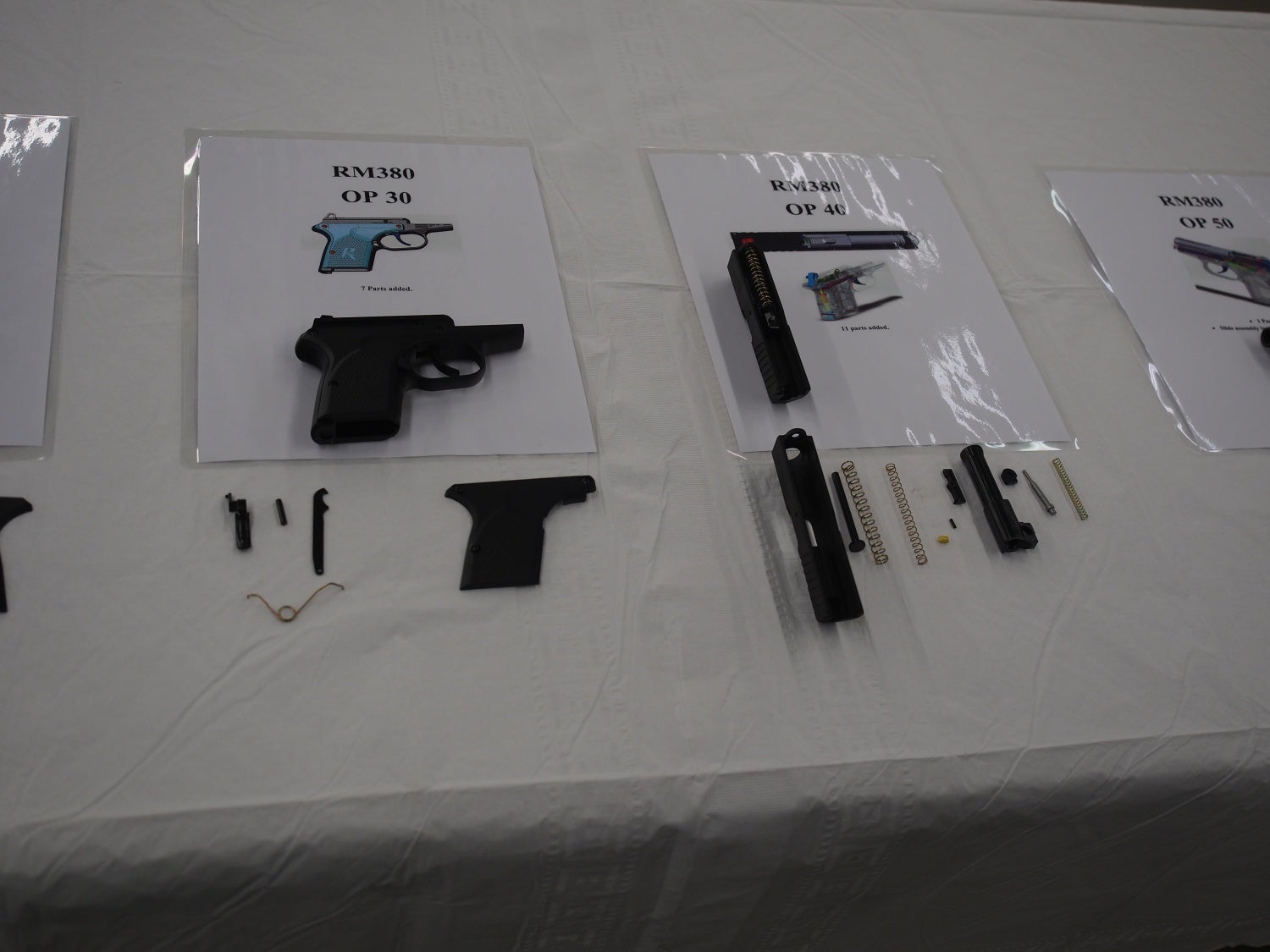

The beginnings of the RM380 in the form of raw steel which when finished will be the slide.

Of course we saw many other areas including R&D, design etc. We also ran across a 3D printer that allows Remington to print full size, aluminum AR 15s. This printer is huge measuring approximately 8x7x5 feet. I would have really enjoyed seeing it run but at the time they had no jobs pending.

After the tour we met with the new CEO and others who make Remington run day to day. All of the executives invited our questions and encouraged us not to hold back. That specifically included the CEO.

I asked the CEO what he saw for Remington down the road and what plans they had for the near future. First he expressed his commitment to getting Remington back to the basics and doing the things which made Remington so successful. This included but was not limited to customer service, quality control as well as something I’ve mentioned numerous times and that’s no more prototype guns being tested and then going straight into production. All new guns will be completely and thoroughly tested before being shipped to dealers.

In the future any events we writers and editors attend we will shoot production guns only. In other words the same guns the customer will buy from the local gunshop. I personally think this is a move in the right direction. I’d much rather write an article on a production pistol rather than a year out prototype R51 than ran fine for us on the range but fell short in production. Nobody in the room dodged that situation and they are very determined it will never happen again. To answer what you must be thinking right now no the R51 isn’t dead and it will be released in its improved form. Those who purchased one and waited so long will get a new R51 unless they have taken advantage of the Remington policy of replacing it with a base model R1 1911 or refund. In keeping with the new policy we won’t have much advanced notice when it comes out in it’s new form but we will let you readers know as soon as we find out.

After our meeting our tour of the Remington plants was concluded. I have to say it’s the first time in a long time I’ve toured a plant and been allowed to photograph anything I wanted without restriction. All of our questions were quickly answered. This was just a refreshing atmosphere for us to work in. Generally some questions I’ve asked at other plants I have toured went unanswered which tends to make me wonder if we are getting all the facts on the questions that were answered.

I have to thank all of those at Remington from the workers on the plant floor to those who scheduled and coordinated our tour to cover a great deal in a very short time. I think I can speak for everyone else when I say we felt welcome wherever we went and everyone was very open. They did an excellent job showing us just what goes into making a Remington gun and how proud the workers are of what they do in their daily jobs. I hope all of the readers have enjoyed this inside look at Remington!

Your Privacy Choices

Your Privacy Choices