This is the third part of a series of posts seeking to describe and analyze the 7.62mm Light Rifle concept promoted by the Americans, and subsequently adopted by NATO in various forms. This series will cover development from before World War II to the present day, but will focus primarily on the period from 1944-1970, which constitutes the span of time from the Light Rifle’s conception until its end in the United States with the standardization of the M16. This article itself deals primarily with the M1E series of modified Garand rifles created at Springfield Armory between 1941 and 1945. However, some rifles in the series are left out, these being the sniper rifle variations (M1E2, M1E6, M1E7, and M1E8), as well as the 7.62mm M1 conversion (M1E14) developed in the early 1960s. My readers should also note that while I consulted a variety of sources to write this article, my narrative heavily favors Bruce Canfield’s magnum opus The M1 Garand Rifle, as it is the most recent and complete source of information on the M1E series that I know of. On some matters, Canfield contradicts earlier sources like R. Blake Stevens’ U.S. Rifle M14 from John Garand to the M21, which is itself an excellent volume.

You can read the other parts of the series by following the links below:

- Light Rifle 1.5: A Clarification (this was written after Part I, but should be read first)

- The Rise And Fall Of The Light Rifle, Part I: Prologue

- To Challenge A Newly Won Throne: Light Rifle, Part II

- Light Rifle, Part IV: The M1 Garand Learns To Rock And Roll

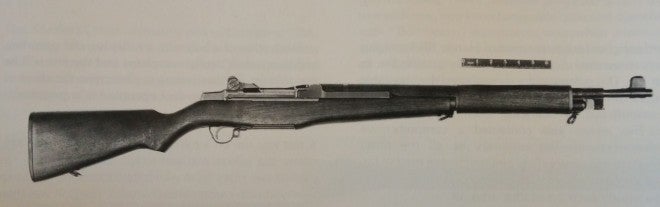

The M1 rifle emerged in 1933 as the first selfloading rifle adopted by the United States, and after a three-year interval was standardized, making it in 1936 the first standard issue selfloading rifle in the world. However, in many ways this signalled the beginning, not the end, of a long road of development that would eventually result in the M1 truly earning the title, through the production of over 6 million units.

The M1 rifle’s “old front end”, the distinctive gas block of the now rare gas trap model. Image source: rockislandauction.com

Our story, though, will focus less on the M1’s service and more on the developments that affected the post-war project to develop a truly lightweight select-fire general issue weapon. The first such project was at the time it was being developed called the M1’s “new front end”. Garand collectors and enthusiasts will be aware that the earliest rifles did not use the gas port operating mechanism that we now recognize on the M1, but a “gas trap”, which was a muzzle device that camptured expanding gas and applied the pressure from it to the gas piston. This system was initially seen as desirable because the entire gas system could be removed and replaced, a major advantage in an era lacking corrosion-resistant materials and noncorrosive ammunition primers. During the development of the rifle and its initial production, however, several problems arose with the gas trap design. First of all, the gas trap was a somewhat dubious mount for the bayonet, and hard use in bayonet fighting could at least hypothetically damage it. Second, the trap tended to catch cleaning patches, which would stop the gun from functioning properly. Additionally, the gas trap – being located at the end of the muzzle – was susceptible to carbon buildup that could stop the weapon from functioning. Frustratingly, this also proved impossible to clean without disassembling the gas trap. Finally, the gas trap could, under certain conditions, loosen, resulting in the next round fired striking it and causing the whole assembly to jettison off the front of the barrel.

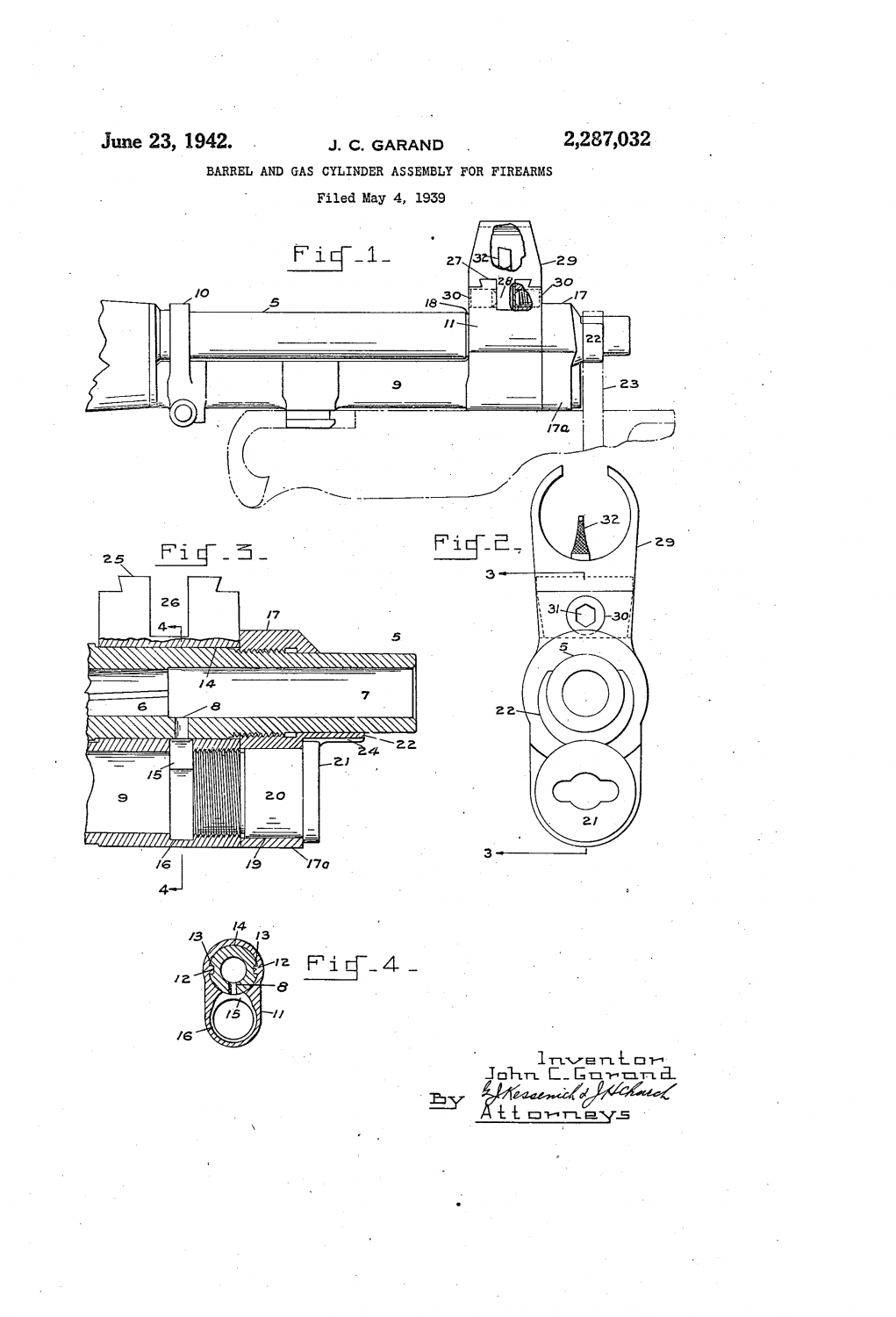

The patent drawing for the M1 Garand’s “new front end”. Note that John Garand has left the last two inches of barrel unrifled; production gas port M1s would have rifling to the muzzle.

Even though this case for redesigning the Garand’s gas system had become apparent by the mid-1930s, it wasn’t until March of 1940 that the new gas port system designed by John Garand had been incorporated into the production drawings for the M1. In fact, the last gas trap Garand left the factory in August of 1940. This coverage of the gas trap Garand and its replacement with the gas port design is decidedly cursory, but the reader should take away that the M1 rifle was originally designed to tap gas from the very muzzle of the barrel, and was later retrofitted with a gas port. Therefore, the length and weight of the M1 rifle’s gas system was not dictated by the ideal location of a gas port system, but by the necessity of the gas trap being at the very end of the rifle’s muzzle, a design that was later replaced.

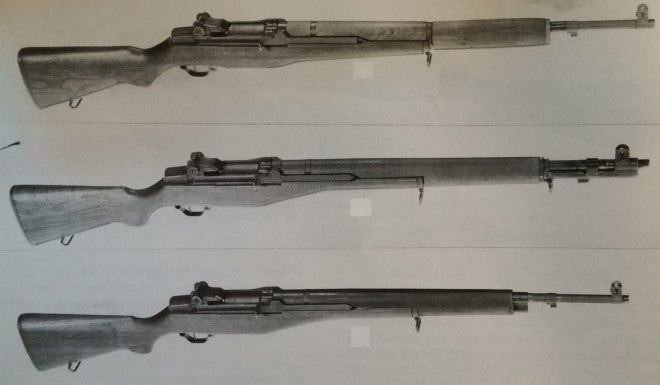

It is for this reason that during the Second World War, Ordnance undertook to design improved variants of the M1 with revised gas systems that would improve the handling and reliability of the rifle, while reducing weight and cost. The modifications to the rifle made during this period, including those with new gas systems, have become known as the “M1E” series. This series also included variants with mechanical improvements, sniper rifle variants that will not be discussed here, and a carbine variant with a folding stock.

Extensive harsh environment testing conducted at the beginning of the war of the M1 rifle revealed that if sufficient lubricant were washed away from the operating rod cam surfaces, then the metal surfaces of the cam track and bolt camming lug would gall and stick together, causing a failure to cycle. One of five possible solutions to this problem were investigated: The first was fluting the chamber to ease extraction, the second was to redesign the operating rod and bolt cam angles to slow unlocking, the third was to improve the finish and surface treatment of the bolt and operating rod cam surfaces, the fourth was to use a special heat treatment for the cam surfaces, and the last was to enlarge the gas port diameter to .100″ to give the action additional power. The M1E1 rifle represented the product of the second solution, and featured a new bolt and operating rod with camming surfaces machined at a more generous angle to slow down the unlocking of the bolt.

Eventually, the solution chosen was the issuance of more water-resistant Lubriplate 130A lubricant, which essentially solved the problem without the need to change any element of production.

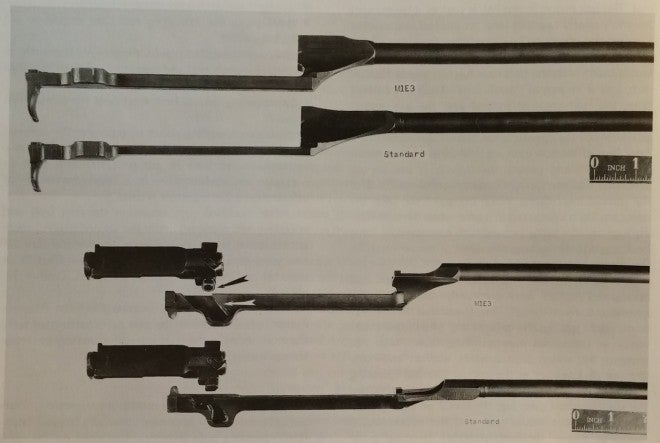

The continuation of investigations into reducing galling of the cam surfaces resulted in the M1E3 rifle, which was the logical conclusion to the M1E1 line of investigation. Instead of simply redesigning the angle of the camming surfaces, the M1E3 introduced a roller cam lug in place of the shaped, fixed cam lug of the original M1 and M1E1. This roller-lug redistributed the friction experienced by the cam surfaces and was perhaps the most successful solution to the galling problem. However, the replacement of the cam lug with a roller came with a downside: The friction-reducing anti-pre-engagement surface of the M1 rifle had to be eliminated in its implementation, but the feeling was that this was well-worth it to fix the galling problem for good. It should also be noted that the roller-lug design as implemented by Springfield Armory did not provide a roller surface between the bolt and receiver, only between the lug and the operating rod.

A comparison between the operating groups of the standard M1 rifle and the prototype M1E3. Visible is the roller lug of the M1E3, a feature much later carried over to the M14 rifle. Image source: Stevens

While the roller-lug design was never implemented in the M1 rifle’s production, it would become a fixture of most of the post-war improved Garand designs.

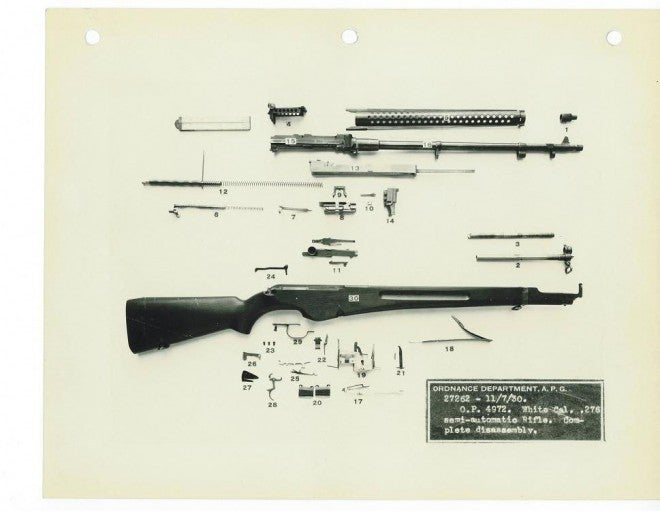

Although the change to the gas port configuration for the M1 fixed the issues that troubled the earlier gas trap models, the new configuration inherited several of the compromises made for the gas trap system. The gas cylinder was situated at the end of the barrel, where it added weight and impeded balance. The gas port tapped gas at the end of the bullet’s travel, when pressure was the lowest. To reach to the end of the barrel, the operating rod had to be long and could be easily bent, and it also complicated manufacture. In short, the gas port M1 worked, but it could be better. In the early part of 1941, Springfield Armory employed one Earl A. Harvey, a former employee of the Stevens-Savage Arms Company, and a person of some importance to the history of the Light Rifle. Prior to the attack on Pearl Harbor by the Japanese, Colonel Rene Studler, the recently-appointed Chief of Ordnance’s Small Arms R&D Division, took notice of Harvey, who would become Col. Studler’s small arms design protege. After an abortive stint in Washington, D.C., cut short by the Japanese attack, Harvey began working on modifications to the M1 rifle’s gas system. The first of Harvey’s experiments was the M1E4, which utilized a new gas cylinder and gas system derived from an obscure .276 caliber contender in the original selfloading rifle trials designed by a Mr. J. C. White, from Boston. The White rifle was submitted in the 1929 and 1930 rifle trials, but was rejected. White’s gas system, on the other hand was promising: In it, gas was tapped into a cylinder and onto a cup-shaped piston. As the piston slid rearward, holes in the cup body that allowed gas to enter the cylinder went out of alignment with the gas port, cutting off gas to the system. The gas that remained in the cylinder continued to expand, driving the piston rearward the full stroke. This system, commonly referred to as the White gas system or “cut-off” system, would become the central operating mechanism for the most important post-war Ordnance rifle projects like the T25, and eventually the M14.

Harvey rediscovered White’s gas system while searching patent filings for ideas for a new gas system for the M1. The first rifle he designed using this system, a hand-made model with no designation, was a crude workshop model. Initial testing of this system showed a gentler velocity curve for the operating rod, and it was hoped that this gentler movement would solve the bolt cam lug galling problem. However, a report published in October of 1943 showed that the gas system did not prevent galling of the operating rod.

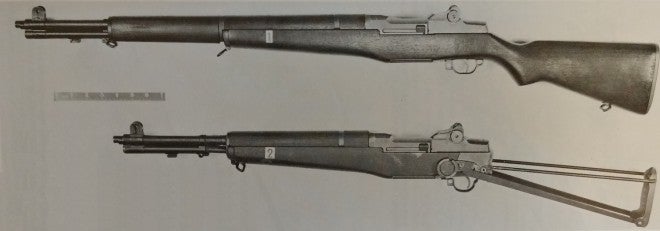

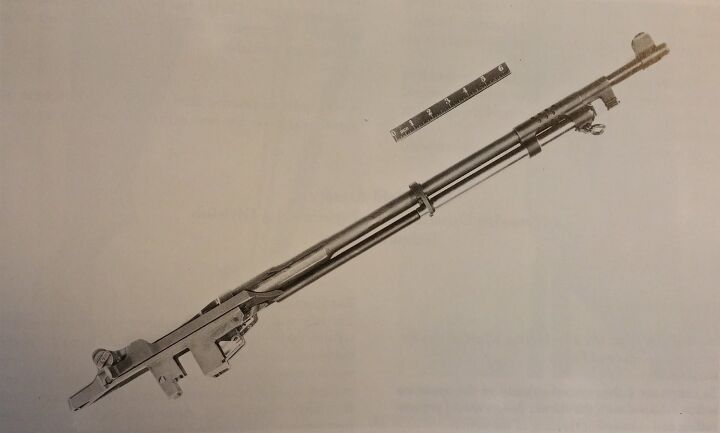

The M1E4 rifle, with stock removed, showing its White-derived gas system. Compare with the image of the disassembled White rifle above. Image source: Stevens

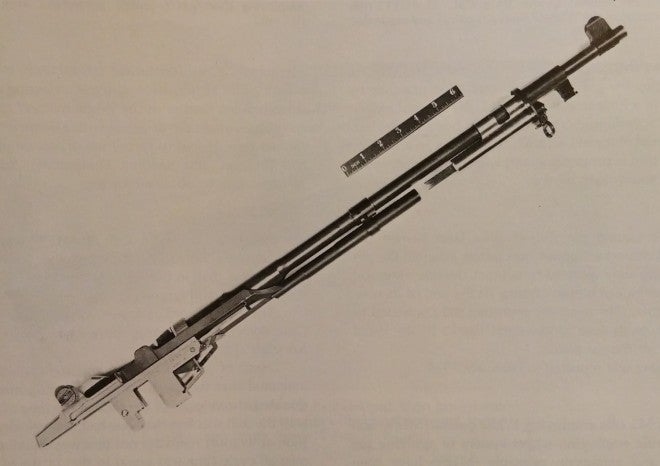

After the rifle had been demonstrated to not solve the galling problem, Studler’s enthusiasm for it cooled, and the production model M1E4 was not finished until August of 1944. This rifle used a two piece fixed piston/operating rod with a female end, and a modified front end with a gas port closer to the breech, replacing the distinctive gas block/front sight combination with a shorter gas block, and separate front sight. Because the gas cut-off piston head and piston body were rigidly connected, this model had problems with severe overheating and inaccuracy, and its springs quickly lost their set due to heat. An improvement of the M1E4 was thus developed in the first month of of 1945, called M1E9, which separated the gas piston and operating rod into two components, thus converting the M1 into a short-stroke design. It was this system that would eventually be incorporated into Earl Harvey’s T25 rifle, and later the Garand-derived T44, which became the M14. The M1E9 also sported distinctive, single-piece upper and lower stocks, and a similar separate front sight and gas block, as in the M1E4.

The M1E9 rifle with its stock removed. Compare to both the image of the M1E4 and the image of the White rifle above. Image source: Stevens

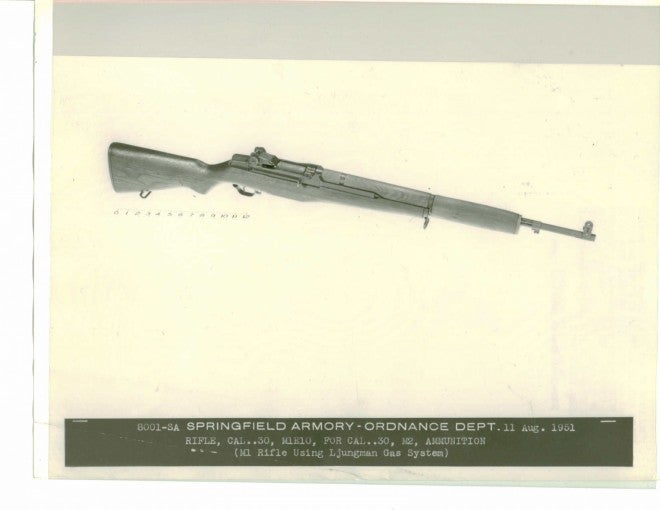

Work on an improved M1 gas system tapped concepts from other countries, as well. One rifle that caught the attention of Springfield’s designers was the Ljungmann AG-42 rifle, the first-generation Swedish selfloading issue rifle. Like the French MAS series of selfloaders, and the later AR-15, the AG-42 utilized a gas tube that piped high pressure gas back to the action to drive the operating group, doing away with the long and easily bent operating rod entirely. A variant of the M1, called the M1E10, utilized the Ljungmann-type gas system to vent gas to an piston-head situated near the operating rod hold-open catch. The M1E10 retained the long operating rod of the M1, but it no longer was acted upon by gas, instead functioning only as a spring guide and additional moving parts mass.

The disassembled M1E10, showing the gas tube, gas vent, and the impinging surface on the operating rod. Image source: Stevens

The M1E10 was determined to be an unsuitable modification to the M1 rifle due to excessive heating to the operating rod, similar to the difficulties encountered with the M1E4.

Harvey also developed two more White gas system prototypes, the M1E11 and the M1E13, the latter of which Stevens describes as an attempt to apply the White gas system to the M1 rifle with as few changes as possible. Sources are conflicted as to when the M1E13 was developed, with Stevens stating it was an earlier prototype than the M1E4 and M1E9, but Canfield holding it as the final evolution of the Harvey-White M1 modifications, and leading directly to the M14. It’s unclear which author is correct, but perhaps there should be greater weight placed on Canfield’s work, as it is both newer, and more congruous with both the rifle’s designation and the earliest prototypes of the T44. The M1E11 is described by Canfield as using a gas cut-off system, but Stevens calls it an application of the Williams tappet gas system to the M1 rifle. It used a cast gas block very similar to the original M1’s, and a single-piece aluminum top and front handguard. Photos of the M1E13 show both of these features, as well, suggesting the two rifles were closely related. Like many of the other experimental gas system prototypes, the M1E11 suffered from overheating and development was discontinued. Photos suggest that the M1E13, in contrast, was the direct predecessor of several post-war improved Garand prototypes that would eventually lead to the M14.

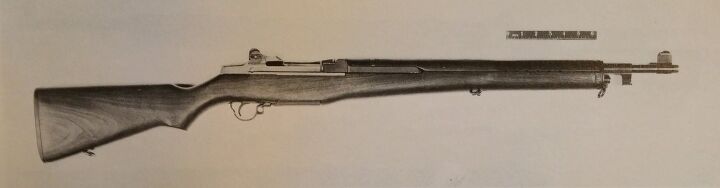

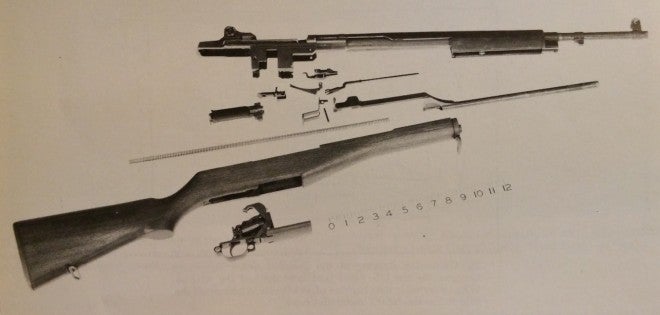

Due to the seeming difficulty of adapting the M1 to other gas systems, there was produced a prototype rifle, called M1E12, that used the same direct gas system as the gas port M1, but with the gas port and gas block moved breechward six inches. The M1E12 was determined to provide no significant improvement over the existing M1, and development was subsequently dropped late in the war.

The M1E12 direct gas piston rifle disassembled. Note the shorter gas cylinder and separate gas block and front sight. Also note the one piece aluminum forward handguard. Image source: Stevens

The M1 Garand itself, like its predecessor the M1903 Springfield, was designed to act both as a carbine and as a rifle, but that requirement dated back to the late 1890s, and with the advent of heavily mechanized and especially airborne troops, a new, smaller carbine was desired. This was one of the primary reasons for developing the M1 Carbine, but by early 1944 there grew a desire to combine the great handling characteristics and light weight of the carbine with the full power rifle round of the M1. After some initial, encouraging tests by the Infantry Board of an ersatz M1 Garand carbine created by the 93rd Infantry Division, Colonel Studler’s Small Arms Divison was tasked with developing a suitable carbine based on the M1 rifle. The designer in charge of this effort was none other than the M1’s designer, John Cantius Garand, and the resulting arm was designated M1E5. This Garand carbine utilized a new 18″ barrel and an underfolding pantograph stock attached to a metal rear stock cap, and was completed in February of 1944. Ordnance tested the M1E5 alongside two modified No. 4 Lee-Enfield rifles that were also shortened to carbine configuration, with, oddly, a standard No. 4 rifle as the control. The tests concluded that the carbines did have increased flash and blast, but that durability, velocity, and accuracy were not significantly reduced. However, testing in May of 1944 at Aberdeen Proving Grounds concluded that the M1E5 had excessive flash and blast, was uncomfortable to hold, and that the stock was fragile and in need of redesign. During testing, an awkward-looking bean-shaped pistol grip was added to the singular M1E5 prototype, to improve handling characteristics. Development was also begun of a new improved stock pattern, but ceased when the project was cancelled. The M1E5 was type classified as Rifle, Type M1A3 but the design was never finished, as other projects were deemed higher priority.

Over the nearly four years that the US fought World War II, the Ordnance Department undertook to improve the M1 rifle’s functioning, handling, and other characteristics. This effort included many projects that will be discussed in upcoming installments of this series, but what is remarkable is that only minor improvements were ever actually incorporated into the production of the M1. Without knowledge of the problems that plagued the rifle, and the effort expended to correct them, some have taken this lack of change as evidence that the M1 rifle was near-perfect, but this is hardly the case. It could instead be taken as evidence of the importance of production over improvement, or that “perfect is the enemy of good enough”, and for the wartime M1 rifles this is probably true. However, the rifles produced from 1952-1957 were not subject to the same overwhelming demand for rifles, and yet still no major changes were made to the weapons, not even enough to warrant a change in designation. This series will explore only a segment of the most important modifications made to the M1 for testing; there were many different ideas explored, from different stock materials to fully automatic M1s, to the different gas systems and bolt configurations discussed in this post. Yet, still, even the M14 which began production only by 1959, and which would have perhaps been better designated “M1 PIP”, represented only a modest improvement at best over the existing rifles. Development of the second generation US selfloading rifle was seemingly agonizing in its slowness and reticence to change. This reluctance on the part of Ordnance to accept the genius at their fingertips and make significant strides forward is one of the major coloring factors in the story of the Light Rifle.

Your Privacy Choices

Your Privacy Choices