At the end of last year, we told you about the US Army Marksmanship Unit’s .264 USA round, which has been designed for an intermediate length AR platform rifle larger than an AR-15 but smaller than an AR-10. The round is one of the first to incorporate polymer case composite construction so early on in its development

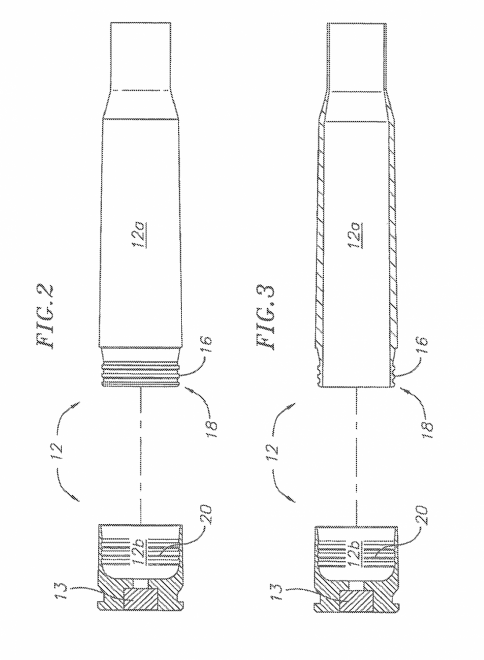

Tony Williams, co-author of the book Assault Rifle with Maxim Popenker, sends along this image of the .264 USA cartridge in both conventional brass-cased and composite brass-polymer case guises:

Alex and Patrick of TFBTV recently related their story shooting composite cased PCP ammunition, and the resultant explosion that could have seriously injured one or both of them. Polymer composite cased ammunition is an ambitious idea, and PCP’s incarnation of that concept is seriously unsafe. Not only has the .264 USA possibly been designed specifically for composite cased ammunition, or at least with it in mind, but the composite cased ammunition itself is not being made by the PCP ammunition company, but rather a company called MAC, LLC, out of Mississippi. One of MAC, LLC’s relevant patents is available here.

Readily apparent from the patent image is the greatly increased thickness of the case wall for the MAC, LLC case design. This reduces the capacity of the case, but is necessary given the use of polymer material in the place of brass.

Additional information about MAC, LLC’s .50 caliber polymer cased project can be gleaned from this presentation from 2012.

Your Privacy Choices

Your Privacy Choices