Over at WeaponsMan, Hognose broaches the subject of “OTMs” and “JHPs” and that they are not the same thing. He writes:

Okay, this is a post about ammunition, and especially, military ammunition, but it also has applicability to police and personal defense use. Now hear this, as the swabbies like to say: Open Tip Match ammunition is not hollow-point ammunition in the sense in which the latter is usually used, to wit, expanding ammunition.

OTM does not differ materially in its expansion and fragmentation from ball ammo. Therefore, it is according to the letter and spirit of the Hague Agreement, perfectly legal.

If an open-tipped match bullet looks like a hollow-point bullet, how does one tell the difference? How does each type perform, and what does “Hague compliant” mean in this context?

These are easier questions to ask than they are to answer, but I will give it my best go. My readers should keep in mind that I am not a JAG lawyer, and therefore anything I say that has legal implications must be taken only as my technical understanding of the subject, and not a declaration of legal fact.

With that out of the way, the first and most easiest answer to the first two questions is “JHPs are designed to meet hunting requirements, and OTMs are designed primarily for utmost accuracy, or in a military context, to meet terminal characteristics requirements.” The reader will note that “military terminal characteristics requirements” cuts both ways; an OTM may be designed to improve terminal effectiveness versus existing FMJs, but it must not do so in a way that violates the Hague. This means, it must have terminal characteristics essentially similar to FMJs, but those may be made more consistent or reliable.

The result of the accuracy requirement is that the jacket is drawn from the base of the bullet, rather than the front as in a conventional FMJ. From a manufacturing standpoint, the bullet is made to be loaded “backward”, and doing this can give several benefits for accurate shooting. Firstly, lead can be inconsistent in form when loaded into a jacket; this means that to achieve the highest consistency, the base of the bullet should be made of harder stuff that can be more consistently shaped into a smooth, even surface. The jacket material is an obvious candidate for this.

In addition, moving the jacket opening (where the core material must be inserted from; on the base in conventional bullets) to the nose provides concentricity advantages. It is difficult to get the edges of the jacket of a bullet perfectly radially symmetrical, and these differences in radial symmetry help create inconsistencies and stability issues when they are further out from the central axis of the projectile’s rotation, as in a conventional FMJ projectile. The OTM design alleviates this greatly by moving the jacket opening to the meplat of the projectile nose, and therefore “closing up” the opening considerably. Some OTMs even take this a step further, and deliberately close the jacket’s opening all the way, with a die.

Doesn’t all this de-facto create a JHP? Sure, maybe it’s done for accuracy reasons rather than to make the bullet drop whitetail better, but doesn’t the opening in the tip of an OTM act for all intents and purposes as a hollowpoint, and doesn’t that imply that OTMs are being used in a military setting with an implied emphasis on their improved terminal effectiveness, with the ostensible reason being “improved accuracy, nudge nudge wink wink”?

Not really. As we’ll see, the OTM has substantial differences to the hunter’s jacketed hollow-point or soft-point bullet. Chief among these is the lack of provision of any striations on the jacket that would facilitate failure points in it, allowing the bullet to “petal” and expand. Most commercial jacketed hollow-point projectiles feature these striations, either internally or externally, and all projectiles approved for general issue by the JAG do not feature them. Since the Hague prohibits:

[T]he use of bullets which expand or flatten easily in the human body, such as bullets with a hard envelope which does not entirely cover the core, or is pierced with incisions.

These striations are therefore not Hague-compliant in the normal understanding of the agreement.

The performance of OTM bullets also more closely resembles that of normal FMJ projectiles than hunting JHPs and JSPs. A standard FMJ projectile may exhibit a combination of tumbling, axial flattening, and/or fragmentation, all of which are accepted as being Hague-compliant terminal characteristics for bullets used in war.

An example of how FMJ bullets perform in tissue. In some cases, the projectile only flattens axially at the cannelure, however some shots fragment, producing more dramatic results. Image source: ar15.com

A well-designed hunting JHP does not exhibit this kind of fragmentation or flattening. Hunting JHPs are designed to frontally expand while remaining stable and, most importantly, intact. In service of this last, the most effective JHPs bond the jacket to the lead core, either mechanically or chemically.

Examples of hunting JHPs. The red arrow points to the terminus of one of the internal striations on the middle bullet, which allows it to neatly expand with the characteristic “petals” of a JHP. The flanking rounds also exhibit JHP-type performance, though they may not have purpose-cut striations. Image source: rathcoombe.net

How do two common OTM-type projectiles compare to these two types? OTMs typically perform very much like FMJs with comparable jacket thickness. Modern Sierra-type OTMs, however, typically use a thinner jacket of about 0.35mm compared to the 0.50mm+ jacket common in military FMJs. This doesn’t drastically change their performance, but it does reduce the velocity needed to induce fragmentation.

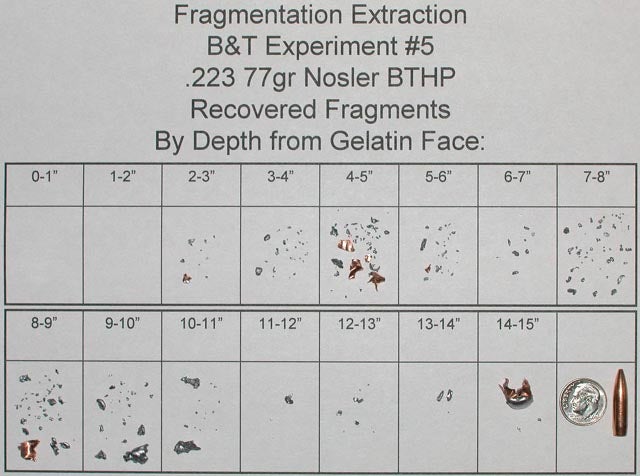

Fragmentation of the 77gr Nosler BTHP. This projectile has been loaded in military Mk. 262 ammunition, and is very similar to the Sierra 77gr BTHP. Note that both Nosler and Sierra bullets are called “Boat Tailed Hollow Points” despite meeting the definition of an “OTM”. Image source: ar15.com

Major efforts to improve the consistency of terminal effect of OTMs have been undertaken, resulting in part in the Mk. 318 round, which is largely supplanting the Mk. 262 in service. This round combines the fragmentation capability of the thin-jacketed OTMs with additional penetration from a solid rear half, while incorporating the yaw independent characteristics refined through the M855A1 program.

This fired Mk. 318 SOST OTM projectile illustrates the typical performance of the round in tissue. The jacket quickly loses integrity, separates from the base, and fragments like a standard FMJ, while the solid gilding metal slug continues on, providing additional penetration and insurance against barriers. Image source: sadefensejournal.com

The Mk. 318 SOST in particular has become controversial primarily due to its resemblance to a commercial hunting projectile, the Trophy Bonded Bear Claw, offered by SOST producer ATK’s child company Federal. However, the two bullets have considerable differences: The SOST round lacks the bonded construction, thicker jacket walls, and wide, exposed lead tip of the TBBC, while the Bear Claw lacks the thin jacket at the cannelure of the SOST round. This last feature induces fragmentation comparable to military FMJ projectiles such as M193 with a lower required velocity.

The Mk. 318 SOST compared to the untipped Trophy Bonded Bear Claw projectile. While their construction is broadly similar, the TBBC features an exposed lead tip of much greater diameter than the Mk. 318 OTM, thicker sidewalls, and a bonded core and jacket. These differences are highlight how subtle changes in a bullet’s construction can lead to very different terminal performance characteristics, evidenced by the neatly mushroomed TBBC on the far right. Image composited from images found at sadefensejournal.com and neveryetmelted.com

The wording of the 1899 Hague Peace Conference does prohibit two characteristics that are widely used in warfare: Bullets which “flatten easily” and bullets “with an envelope which does not entirely cover the core”. Virtually all FMJ spitzer projectiles flatten easily in tissue, “pinching” easily at their waists as they tumble in tissue. The 1899 Hague could not have known about these later developments, however, as the first high velocity spitzer projectile to enter service had only done so a year before, and it would be another six years before jacketed lead-cored spitzers were popularized by the Germans. The construction of these bullets was identical to the older FMJ round-nose projectiles, but their terminal characteristics were different, something that was not fully understood until after World War II.

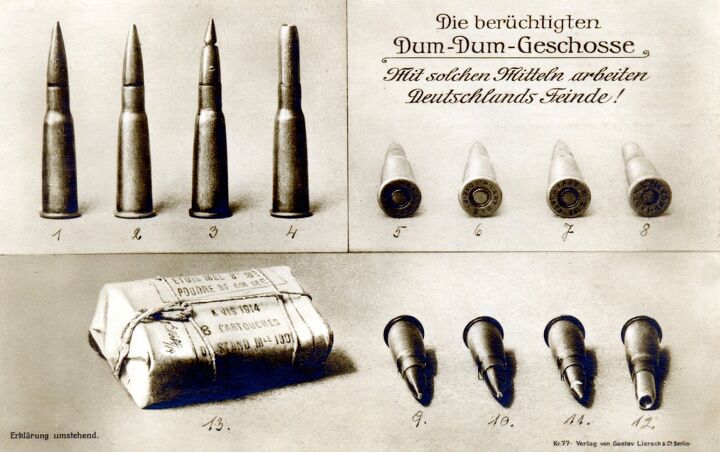

Some of the types of projectiles prohibited by the Hague Peace Conference of 1899. Cartridge number 3 makes it very obvious what the wording “piercings or incisions” was meant to prohibit. Image source: semperfidelis.ro

So the high-velocity spitzer FMJ has to get a pass; it was invented after the Hague, and not understood to be violating the letter of it until well after they had become ubiquitous in use. Since all the Hague nations use it, it’s not a problem.

Which brings us to the “envelope which does not entirely cover the core”. It’s more clear what this refers to; the Hague does not prohibit the round-nosed FMJs that were common at the time, which do have an exposed opening at the rear, the common “dum-dum” improvised round had a large section of its jacket removed, exposing the lead core underneath. Later factory rounds would partially cover this core, but still expose a large hole through which the lead could expand or separate from the jacket. The wording of “entirely cover” is still ambiguous, but the expanding rounds that were available at the time give some insight into the intent of the Hague authors. A standard OTM covers its core, and even though there is an opening in the tip of the projectile, a reasonable application of the Hague prohibition could exempt OTMs.

Despite this explanation, the nomenclature used by commercial entities continues to cloud the issue. As previous mentioned, both Sierra and Nosler call bullets legally classified as OTMs “Boat Tailed Hollow Points”, and many other manufacturers make bullets that perform identically to OTMs (though they may not be constructed in the same way) without qualifying in the most technical sense as either OTMs or JHPs. These, too, are often called “hollow point” rounds, despite the fact that they neither expand, nor do they have the characteristic closed base of modern match bullets. It’s not a problem to call these rounds “hollow points”, so long as it is understood that they don’t perform in such a way that violates the 1899 Hague.

One thing this segment does not cover is pistol-caliber hollow point ammunition. Because that ammunition is designed for much lower impact velocities than rifle ammunition, only the most fragile projectiles will fragment to any degree, and therefore the vast majority of open-tipped pistol projectiles fall squarely outside the Hague’s limits. This is the reason there has been little development of pistol-caliber OTM equivalents for military use.

I will close with another quote from Hognose’s article on the legal implications of these differences:

If your objective is not to aggravate the wounding effect or suffering, and the round does not have that effect (as is the case with OTM which has, as well documented by Parks and elsewhere, expansion and fragmentation statistically indistinguishable from FMJ ball), then your round is legal, full stop.

Your Privacy Choices

Your Privacy Choices