The 5.56mm M855 round has received considerable criticism for its terminal characteristics. Detractors point out that the round fails to fragment when the striking velocity is too low – such as when fired from a very short barrel or when the bullet has slowed down thanks to its relatively unimpressive ogive shape – or when the bullet strikes the target at a very low angle of attack.

That’s one reason why it’s extremely puzzling to me that one of the most popular 5.56mm replacements – and the round many think offers the military a commercial-off-the-shelf improvement in effectiveness – offers even less in these criteria than even M855. That round is the 6.8mm Remington Special Purpose Cartridge.

The history of the 6.8mm SPC round is not the subject of this article, but some background on the cartridge’s origins can be found on page 153 of The Black Rifle II: The M16 Into The 21st Century, by Christoper R. Bartocci:

[I]n early 2002, soldiers of the 5th Special Forces Group (Abn), headed by MSG Steven Holland, received approval to initiate a Proof of Concept to develop a new capability that would increase incapacitation, lethality, and range over the existing 5.45x39mm, PRC 5.8x39mm, 7.62x39mm and 5.56x45mm NATO cartridges. This initiative was a grassroots effort aimed at providing better combat power for Special Operations Forces and soldiers of the Light Infantry, to include USMC MEU-SOC. This was the original programmatic evolution proposed for the SOPMOD Mk12 Special Purpose Rifle (SPR) system, the interim result of which was the fielding of the Mk262 77-grain ammunition, with a planned later transition to the Enhanced Rifle Cartridge (ERC) capability in a mid-bore 6.5mm, 6.8mm or 7mm caliber.

With the already proven combat success of the Mk12 SPR, the SPR concept-development team went to manufacturers in the US ammunition industry for assistance.To initiate the program, the companies involved in the development agreed to do so at their own expense, with the goal that the final product would provide US servicemen with a better capability and morale boost to combat the Global War on Terrorism (GWOT).

The assessment of the initial performance capabilities of the prototype cartridges, based on shortened commercial .30 Remington cases, was handed over to the USAMU Ammunition Section, headed by Troy Lawton. Industry involvement to consider this project at no cost to the government was championed by Sean Dwyer at Remington, who stated that Remington wanted to do their part on the Global War on Terrorism, and provide production capability for the ammunition, which would be developed and manufactured by Remington using bullets provided by Sierra and Hornady.

Several propellants were reviewed to provide improved powder performance, including Western Powder’s Ramshot, and submissions from Accuracy Arms and St. Marks Powder Company. These companies developed powders particularly for the 6.8mm Remington SPC cartridge, and will supply quantities of the chosen propellant for final assembly of ammunition by Remington. The Special Forces SPC team require that the powder used is to be manufactured in the United States, and contain an organic flash inhibitor to decrease muzzle flash in low light conditions.

Remington began the final development of the SPC cartridge in the fall of 2001, using concept wildcat brass made up by MSG Holland from shortened .30 Remington cartridge cases. AutoCAD drawings of the prototype calibers in the same cartridge case were prepared by Cris Murray of the US Army Marksmanship Unit. Remington went to work to standardize the angle of the shoulder and length of the neck. Early experimental production of ammunition began at Remington in the first quarter of 2002, and went into full production in August, 2003. During this time period several ballistic performance assessments, including accuracy and reliability- incapacitation tests, were conducted. Special Purpose Cartridges in 6.5mm, 6.8mm and 7mm calibers were reviewed to determine which bore size would best provide the capability needed by soldiers in combat. Once all the performance data were compiled the team briefed the Commander on the results, and recommended that the 6.8mm provided the best overall terminal, reliability and accuracy performance out to 450 meters. This recommendation was approved. The 6.8x43mm Remington SPC Terminal Performance results were independently confirmed by the Federal Bureau of Investigation’s Firearms Training Unit as well as by USNR/Stanford University.

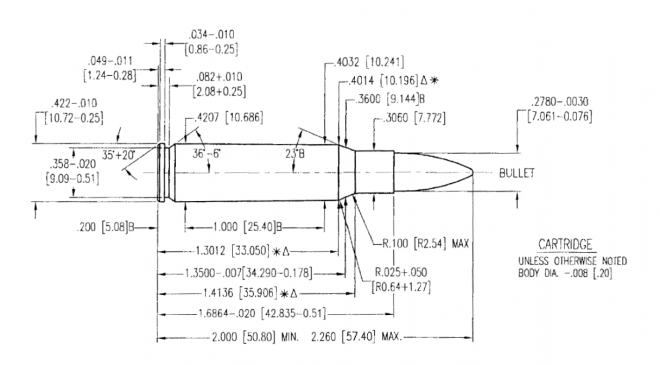

It’s worth examining the dimensions of 6.8mm round itself in detail. The cartridge case is based on the rimless .30 Remington, and uses the same extractor groove and rim dimensions, with a rim diameter of .422″ or approximately 10.7mm. It uses the same case taper and shoulder angle as the 5.56mm rifle cartridge, the beta angles of those being 0.5 and 23 degrees, respectively. The round has a maximum case length of 1.6864″, or 42.83mm. Its overall length is the same as 5.56mm, at 2.26″/57.4mm, though some magazines are advertised as offering overall lengths as long as 2.315″/58.8mm, and the purpose-built Six8 rifle from LWRC, which uses proprietary magazines, offers an overall length of 2.32″/58.9mm. The cartridge has a case capacity of between 34.8 and 36.9 grs H2O (2.255-2.391 ccs), 14-21% more than the 5.56x45mm. It uses standard .277″ diameter projectiles, although it is limited in its selection of those by the overall length. In general, though the projectile diameter is the same, the 6.8mm Remington requires totally new projectiles versus existing .270 caliber rounds.

The SAAMI cartridge drawing for the 6.8mm Remington Special Purpose Cartridge. Note the tolerances shown in the image after “-” signs; they will not be discussed in this article. Image source: SAAMI.org

It is very curious to me that a round that was designed with an accurized designated marksman’s rifle in mind also features such a short ogive and low muzzle velocity. Typically, medium/long range precision weapons platforms place a premium on both the ballistic coefficient and velocity of the projectile, seeking to obtain as laser-like a trajectory and as high a retention of energy as possible. The 6.8mm SPC runs directly counter to this.

The ogive of a bullet is the curved portion of the projectile that is exposed outside the case. The ideal bullet shape includes as long a bullet ogive as possible, while keeping the shape as close to that of a Sears-Haack body as possible. Increasing the ogive length either increases the cartridge overall length or necessitates a decrease in case length (reducing its capacity, unless the case head diameter is increased). In terms of cartridge design within a given OAL, longer ogives come at the price of less case capacity and therefore lower muzzle velocity, but in general accepting this comes with the benefit of better velocity retention over distances beyond about a hundred meters.

In light of this, the 6.8mm SPC’s maximum ogive length is the first curiosity of the cartridge’s design. With only 2.07 calibers available space for the ogive, the maximum ogive length for the 6.8 SPC is less even than that of the 5.56x45mm or 7.62x39mm cartridges. This is very short for a rifle cartridge designed for maximum performance out to 450 meters, and limits the form factor of compatible secant-ogive projectiles to above 1.15 i7 (lower form factors yield higher ballistic coefficients), with tangent ogive projectiles having form factors as high as 1.32 i7. For comparison, the M855 projectile offers a 1.166 i7 form factor, despite not being particularly well streamlined. Finer projectiles compatible with the 5.56mm round offer i7 form factors as low as 1.09. Even when magazines allowing longer ogives are used – which it should be noted also would allow the use of longer and finer 5.56mm projectiles – the available relative space is still not significantly greater than that of the 5.56mm and 7.62x39mm cartridges. Further, as of yet there do not seem to be any manufacturers making .277″ projectiles with ogives designed for these longer magazines, and thus they only offer a velocity advantage to handloaders seating existing short-ogive bullets less deeply in the case.

This means that – at best – the 6.8mm SPC round can accommodate projectiles with a similar ballistic shape to the M855 round. Improved projectile shapes – including some that would be compatible with the 5.56mm standard – are not compatible with the 6.8mm SPC cartridge when loaded to standard magazine lengths.

This is further exacerbated by the 6.8mm’s restrictions on fineness ratios. The fineness ratio of a projectile is the ratio of its length to its diameter, and this is a factor in the projectile’s ballistic coefficient (typically, bullets with high fineness ratios have better ballistic coefficients). Because of the 6.8mm SPC’s wider projectile, accommodating higher fineness ratio bullets (such as M855A1-style lead-free projectiles) is more difficult, and more significantly reduces the case capacity of the round. This is closely related to the relative capacity of the round.

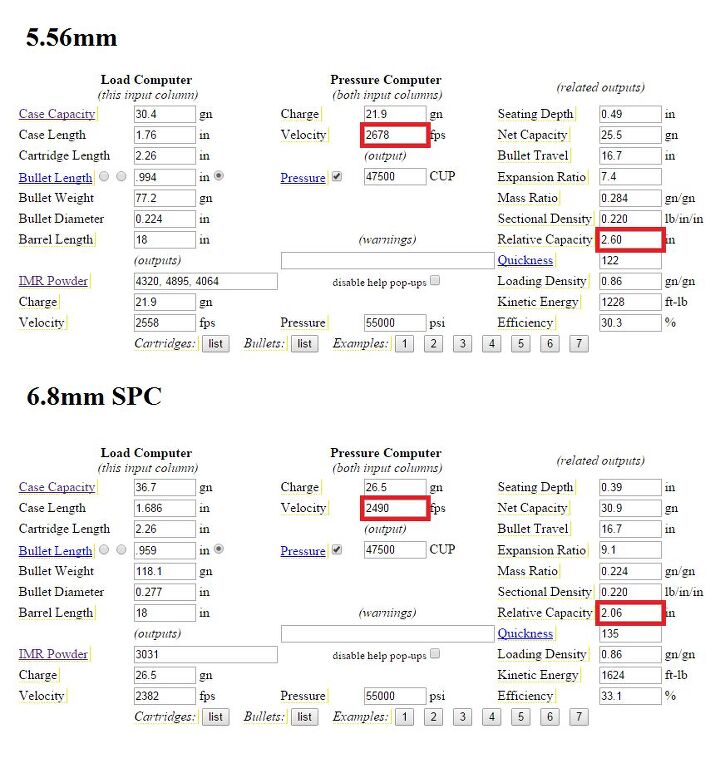

Compared to rounds like the 5.56mm or 7.62x51mm, the 6.8mm SPC has a poor relative capacity. This is the ratio of the case capacity to the cross-sectional area of the bore, and is an important predictor of performance. A ballistically ideal round propels a bullet with a high sectional density and high fineness ratio at high velocity. The relative capacity of the round is closely related to that round’s ability to propel high sectional density bullets at high velocities. A good example of this is given by comparing the 6.8mm SPC to the 5.56mm Mk. 262, with bullets of identical sectional density, using the simple Powley computer available at kwk.us:

A 5.56mm round compared to a 6.8mm round. Note that the 5.56mm has a higher relative capacity by 25%, and that it also has a a considerably higher muzzle velocity. This is because a round’s relative capacity is closely related to its suitability for propelling bullets of a given sectional density to higher velocities. The parameters for these calculations were chosen to keep the comparison constant. Both rounds are operating at the same pressure (the MAP for 6.8 SPC; 55,000 PSI), and both projectiles are based on real projectiles (the 77gr 5.56mm being based on the Sierra 77gr projectile from Mk. 262, and the 118gr projectile of the 6.8mm SPC being based on the Sierra 115gr projectile, with mass increased to keep sectional density constant with the 77gr 5.56mm projectile).

However, the relative capacity does not tell the whole story. A round with a lower relative capacity may have a higher velocity with projectiles of a given sectional density than another round, if it develops more pressure. Higher pressure cartridges are both more thermodynamically efficient as well as more mass efficient than lower pressure ones; they require less case volume (and thus less case mass) to produce the same velocity. In this, too, the 6.8mm falls behind, for reasons that will be explained below. Current 5.56mm ammunition (with the notable exceptions of M855A1 and Mk. 262) has a maximum average pressure of about 58,000 PSI, meaning the results shown above are somewhat muted versus reality. Further, while older Mk. 262 ammunition produced pressure comparable to the M855 round, current Mk. 262 ammunition utilizes more thermally stable propellants than previous 5.56mm rounds, allowing a MAP of about 68,000 PSI. Because the Powley computer was not designed to provide accurate calculations at pressure levels this high, I will not use the computer to produce data for this pressure level. From an 18″ SPR barrel, however, the Mk. 262 round typically produces velocities of about 2,800 ft/s, which translates to 9.3% more energy than the example above.

It’s therefore useful to be able to quantify this additional factor of pressure in some way. While it is not generally used in the relevant literature, I have chosen the term “internal specific energy”. To calculate this, take the relative capacity value and multiply it by the maximum pressure (giving units of lbf/in in English, or N/cm in Metric). This value is a hint only, as total work performed on the bullet is only roughly represented by the maximum pressure; for example, a round with slower-burning propellant may give higher velocities with a given bullet than one with faster-burning propellant, despite both having the same maximum pressure. It’s therefore wise to use this quantity only as a guide for sound cartridge design.

How, though, should we compare the pressures of 5.56mm and 6.8mm? 5.56mm has a given maximum pressure of about 58,000 PSI, but what about the higher pressure Mk. 262? Should only cartridges of the same pressure be compared? The answers to these questions depend on the purpose of the analysis, however for military rifle cartridges pressure is most important for its relationship to the strength and fatigue life of the locking mechanism of the rifle. All things being equal, a higher pressure round will stress a rifle’s locking mechanism more than a lower pressure one. However, the actual determiner for the stress exerted on the locking mechanism is a quantity of force not of pressure. The quantity that best represents the stress a given round will put on the locking surfaces of a rifle is bolt thrust (expressed in lbf in English and N in Metric), which is the force created against the locking lugs by the cartridge during firing. This quantity is the maximum pressure of the round multiplied by the maximum internal area of the case. For the purposes of this analysis, the maximum internal area of the case can be approximated by the formula below:

maximum internal area = pi * ([case head diameter – .033″] / 2)^2

To find the relative bolt thrusts of the 5.56mm and 6.8mm rounds, we find the result of the equation and then multiply it by the maximum pressure of each respective round.

5.56mm:

Case head diameter: .378″

Maximum pressure: 58,000 PSI

Maximum internal area: 0.0935 in^2

Bolt thrust: 5,432 lbf

6.8mm SPC:

Case head diameter: .422″

Maximum pressure: 55,000 PSI

Maximum internal area: 0.1188 in^2

Bolt thrust: 6,537 lbf

The 6.8mm SPC round evidently puts much more stress on the rifle’s bolt than the 5.56mm round, which may cause the bolt to break sooner. For the 5.56mm round to produce as much bolt thrust, pressure would have to be increased to nearly 70,000 PSI. Therefore, the Mk. 262 Mod. 1 round, despite its very high maximum pressure of 68,000 PSI, actually puts less stress on a rifle bolt than the standard 55,000 PSI pressure 6.8mm SPC round. Since both rounds occupy comparable roles and both rounds were originally intended for the same platform (the Special Purpose Receiver, later Mk. 12 Special Purpose Rifle), it seems reasonable to therefore compare them directly against each other. First, we will calculate the rounds’ relative internal energies:

5.56mm (Mk. 262 pressures):

Relative capacity: 2.60 in

Peak pressure: 68,000 PSI

Internal specific energy: 176.8 x 10^3 lbf/in

6.8mm SPC:

Relative capacity: 2.06 in

Peak pressure: 55,000 PSI

Internal specific energy: 113.3 x 10^3 lbf/in

5.56mm’s 56% higher Eisp value suggests it has better ballistic potential than the 6.8mm’s. That, coupled with the 6.8mm’s shorter available ogive space indicates that the 5.56mm may be more ballistically optimal. To verify this, however, the two cartridges must be compared on more substantial terms.

As previously mentioned, it is beyond the limitations of the Powley Computer to generate velocities for the Mk. 262 round due to its high pressure. Powley calculations are also not truly representative of the performance possible from the 6.8mm SPC round, due to Powley being limited only to older IMR-type propellants, where the 6.8mm SPC performs best with newer propellants such as H335. For these reasons, when examining the ballistics of both the Mk. 262 round and 6.8mm SPC, I will be using non-calculated, non-empirical velocity figures based on the common performance of the two rounds. While the velocities used are not taken from any particular sources (as it is very difficult to find a truly controlled evaluation of the two rounds), I have done my best to choose figures representative of the actual performance of the two rounds from 18″ barrels with Spec II or DMR chambers.

To properly compare the two rounds, it will also be necessary to choose two different types of OTM projectiles in each caliber: Sierra’s tangent-ogive BTHP and Hornady’s secant-ogive BTHP. Ballistic coefficients for all four projectiles will be taken from the ballistic coefficient resource on my blog. In both cases, the Hornady secant-ogive projectiles give lower form factors and thus higher ballistic coefficients, due to their conforming more closely to the Sears-Haack body shape. Further, both lighter secant-ogive projectiles will be calculated with the same muzzle energy (and thus slightly higher velocity) than both tangent-ogive projectiles; this is representative of pulling a loaded tangent ogive bullet from the case and replacing it with a secant-ogive one.

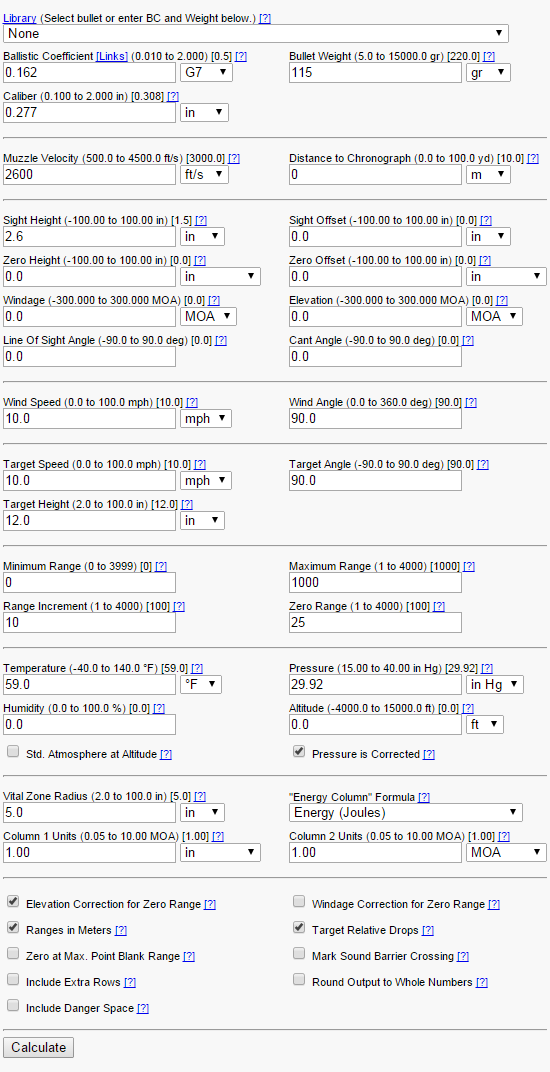

To make an accurate ballistic comparison between the 5.56mm and 6.8mm rounds, we will use JBM Ballistic’s excellent external ballistics calculator. The settings used are reproduced below:

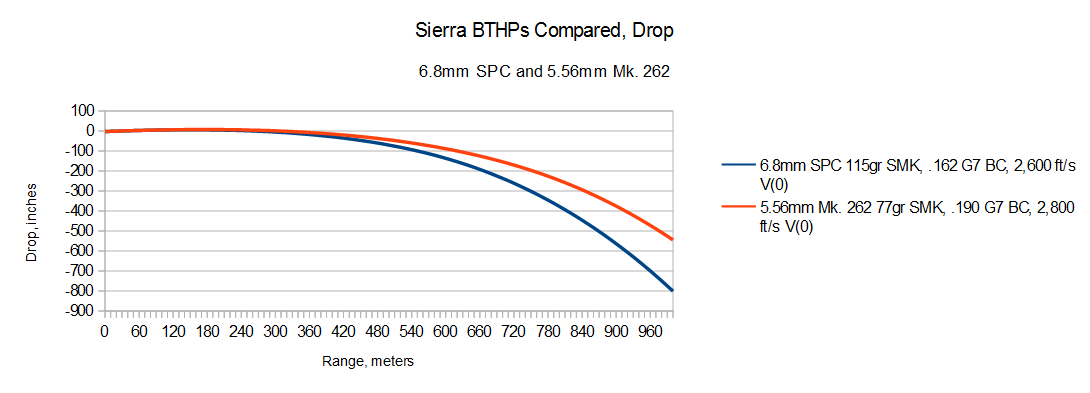

First, we compare the 77gr Sierra MatchKing BTHP with cannelure against the 115gr Sierra MatchKing BTHP with cannelure in terms of drop, wind drift, retained velocity and retained energy. The results are graphed in Excel and produced below:

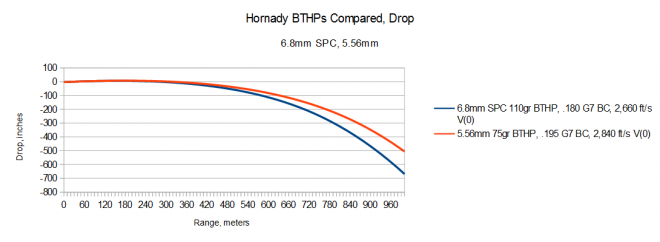

The Sierra BTHPs compared for drop. If the PEO Soldier criteria for maximum effective range is applied (the range at which the round has comparable drop to the M855 round at 500m when fired from an M4 Carbine), then the 6.8mm SPC has an MER of 450 meters, while the 5.56mm Mk. 262 has an MER of 510 meters.

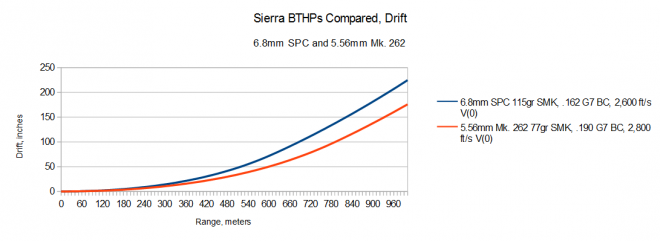

The Sierra BTHPs compared for wind drift. Counterintuitively, the lighter 5.56mm bullet bucks the wind better than the heavier 6.8mm.

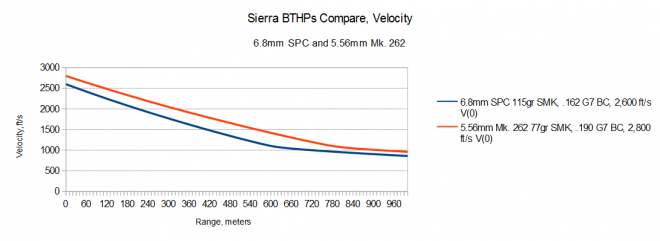

The Sierra BTHPs compared for velocity. If a fragmentation threshold for the Sierra BTHP of 2,000 ft/s is used, the 6.8mm SPC will only fragment when it hits targets 210m away or closer. When the same fragmentation threshold is applied to the 5.56mm Mk. 262, it will fragment when striking targets 320m away or closer, a full 50% increase. Further, the 6.8mm enters the transonic flight regime (passing below Mach 1.3) at 430 meters range, and becomes subsonic at 590 meters. The 5.56mm enters the transonic regime at 580 meters range, and becomes subsonic at 770 meters.

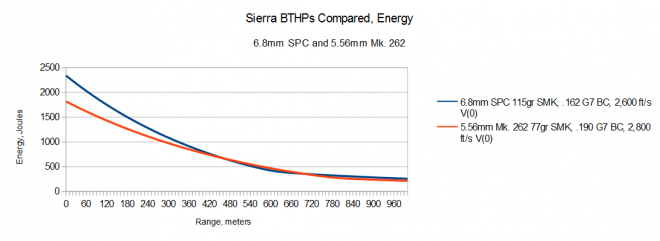

The Sierra BTHPs compared for energy. Beyond 300 meters, the 5.56mm Mk. 262 has 90% of the retained energy of the 6.8mm SPC or better. Between 470 and 700 meters, the 5.56mm actually possesses more retained energy than the larger 6.8mm.

Comparing the Sierra BTHPs illustrates the considerable shortcomings the 6.8mm has in both ogive length and velocity. Despite being larger and more powerful, the 6.8mm SPC 115gr quickly spends its advantage in muzzle energy and offers virtually no ballistic advantages beyond 300m over the 5.56mm 77gr Mk. 262.

The Hornady secant ogive BTHP rounds, however, are closer to each other in both ballistic coefficient and velocity, which should improve the 6.8mm’s lackluster ballistics somewhat. They are compared below:

The Hornady BTHPs compared for drop. If the PEO Soldier criteria for maximum effective range is again applied, then the 6.8mm SPC has an MER of 470 meters, while the 5.56mm Mk. 262 has an MER of 520 meters.

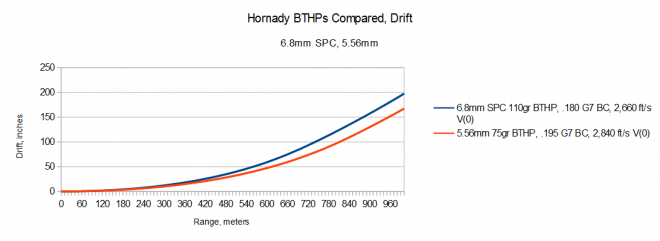

The Hornady BTHPs compared for wind drift. While the secant ogive helps close the gap between the two rounds, the 5.56mm 75gr BTHP still handles the wind better than the 6.8mm SPC.

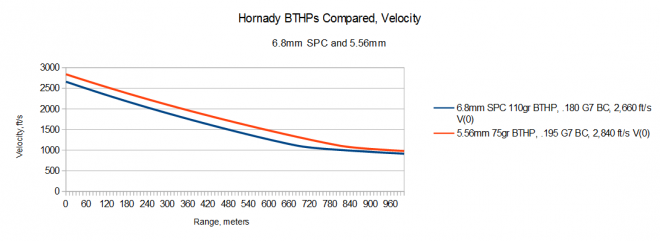

The Hornady BTHPs compared for velocity. If the same fragmentation threshold as the Sierra BTHP is used for the Hornady BTHP, the 6.8mm SPC 110gr BTHP will fragment when it hits targets 250m away or closer. The 5.56mm 75gr BTHP stays above the same threshold when striking targets 340m away or closer, shrinking the gap between the two rounds to a 36% advantage for the 5.56mm. The 6.8mm Hornady enters the transonic flight regime (passing below Mach 1.3) at 500 meters range, and becomes subsonic at 680 meters, a considerable improvement over the Sierra load for the same caliber. The 5.56mm Hornady BTHP enters the transonic regime at 610 meters range, and becomes subsonic at 810 meters.

The Hornady BTHPs compared for energy. The higher ballistic coefficient of the secant-ogive Hornady BTHP has improved things for the 6.8mm SPC. Only beyond 490 meters does the 5.56mm 75gr BTHP have 90% of the retained energy of the 6.8mm or better, this time. With the ballistically superior Hornady projectiles – though they come very close – the 5.56mm never exceeds the retained energy of the 6.8mm.

What this analysis makes clear is that the theoretical limitations of the 6.8mm SPC have a very real impact on its ballistic performance. Despite being designed to improve the performance of SPR-type rifles to medium ranges, the 6.8mm SPC when loaded with Sierra projectiles offers no improvement over current 5.56mm Mk. 262 ammunition except in terms of raw energy provided at ranges below 300m. Even with the ballistically superior Hornady BTHP projectiles, the 6.8mm SPC sacrifices important characteristics such as drop, wind drift characteristics, and a longer maximum fragmentation range for an advantage in muzzle energy that becomes increasingly small as distances approach 500m.

It must be remembered, however, that modern Mk. 262 did not exist at the time of the 6.8mm SPC’s development; the Mk. 262 ammunition at that time produced up to 200 ft/s lower muzzle velocities than current ammunition. Compared to that early ammunition, the 6.8mm SPC would offer a more substantial advantage in energy at short-medium range, even with a less impressive ballistic coefficient. However, at the same time the 6.8mm SPC’s chamber dimension issue had not yet been solved, and by the time it was solved (twice – by the Spec II chamber and by the DMR chamber), modern, high-pressure Mk. 262 ammunition had become available.

None of the above is intended to say that the 6.8mm SPC cartridge is unwanted or isn’t useful. The round offers hunters a 50-state legal medium game round with a good selection of effective bullets and accurate factory loads, that is compatible with the AR-15 rifle after relatively minor modifications that can be made with few tools and relatively little effort. Its additional available energy certainly makes it a more comfortable round to use for this task than the 5.56mm, while it has considerably better ballistics – especially with secant-ogive projectiles such as the 110gr Hornady V-Max – and projectile selection than the 7.62x39mm round.

In fact, had the 6.8mm SPC been introduced in the 1930s or ’40s, or had it been introduced as a dedicated medium game round (a sort of latter-day .30-30 to the .223 Remington’s .25-35, perhaps), I would have never taken the time to write the above analysis. It is the round’s serious limitations in the role for which it was designed – as a designated marksman rifle cartridge – that has made me take a closer look at its capabilities versus the round it was intended to replace. And after that, I am still a bit puzzled by it.

Your Privacy Choices

Your Privacy Choices