I think I may have found a fun place to work…

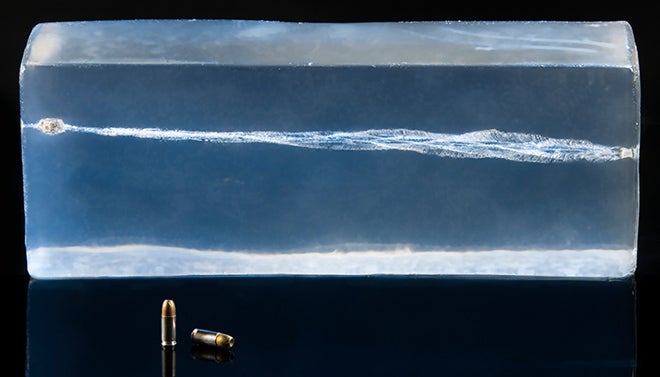

Chesapeake Testing now offers ammunition testing in accordance with SAAMI, FBI, and NATO protocols.

Our in-house calibration system allows for greater repeatability in testing, more accurate data sets, and fast turn-around time.

This is how you actually test and evaluate ammo and weapons…

I’m not sure if this is something that can be used (or would even be cost effective) for testing personal reloads, but it is fairly interesting. I’d never actually considered how ammunition was tested (naive, yes I know).

Tests include:

- Pressure & velocity measurement

- Proof testing

- Cook-off testing

- Less-than-lethal testing

- Projectile characterization

- Quality control inspection

- Performance evaluations for accuracy and dispersion

- Corrosive primer testing

- Primer sensitivity testing

- Environmental testing

Chesapeake also actually tests firearms and has a number of ranges that can accommodate test firing weapons up to 120mm.

Fact sheet: http://chesapeaketesting.com/downloads/pdf/AmmunitionTestingFactSheet.pdf

Your Privacy Choices

Your Privacy Choices