Recently the author embarked on heavily modifying a Kimber Custom II Series 80 style 1911. In the process he ordered custom parts, some of which will be reviewed on TFB. Some of the parts he ordered were from proven companies such as Ed Brown and Wilson Combat. Other parts were acquired from other companies, such as VZ Grips and WePleadThe2nd holsters.

VZ Grips was founded by a gentleman named John VanZyck and is based in Florida, specifically in Tallahassee. The owner is very prominent in Northern Florida shooting organizations and active with the NRA. Currently the company’s claim to fame is that their grips are in use by “USMC Force Recon, Navy SEAL teams, Homeland Security, U.S. Border Patrol, FBI, LAPD, numerous SWAT teams throughout the country, [and the] Jordanian Elite Security Force”. What really sets them apart is their use of G10 and Micarta materials instead of using polymer or rubber. As stated on their website, these are the reasons why-

1. Durability: They have a higher tensile strength than steel. It is used in storm shelters to provide state of the art protection rooms to ward off the threats from tornadoes. It is also being tested to armor aircraft cockpit doors.

2. Impervious to changes in temperature: This material will not swell, warp, or crack with changes in temperature. It is an excellent insulator against heat. Unlike other so called high-end grips on the market, ours stays cool and comfortable.

3. Texture: When milled, Micarta and G10 gives a highly slip resistant surface.

Before going with VZ grips, the author was curious as to just what Micarta and G10 materials were. Not pretending to fully know what the difference is as the author doesn’t have a wood or machinist background, here is an explanation of the differences between the material from an email from the company-

G-10 and Micarta are composites made by bonding layers of material together. Essentially, Micarta is made from cloth (aka natural fibers) and G-10 is made primarily from layers of silica (man-made) glass fibers. G-10 is very dense, and very durable. Both have to be machined, like metal. Both are far more durable than polymer, which is plastic, and typically gets molded to form. In terms of mass production, polymers are usually the least expensive way to make something, as compared to material that has to be machined from a solid to create an end product.

Although most of the companies grips are orientated around 1911 handguns because of the huge market for that pistol, they make grips for a number of other handguns as well, to include the Hi Power, Sig Sauer, Beretta, Rohrbaugh, Ruger, Smith & Wesson, and CZ. Most of their grips can be ordered with a various array of colors, designs, and textures, but it is their 1911 category that is truly custom tailored. Customers can choose from the Custom Engraving category and have options from the thickness of the grip, the safety cut, or the profile of the grip. Within this category you can also choose a custom engraving, which will be an image no larger than the size of a quarter engraved on the grips.

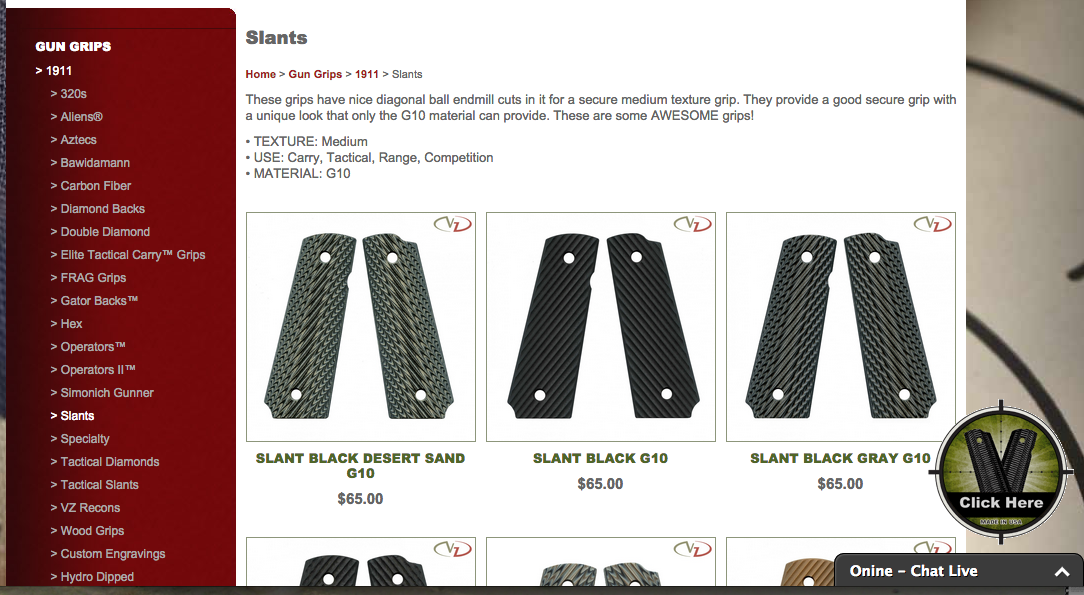

From the VZ Grips website, they have an interactive chat on the side. Although most of their grips are for 1911s, they have numerous others for different handguns.

Most of the basic grips already listed on the website are sold for $60–$75. The custom engraved grips, a pick from the custom products already listed will run around $80, with custom engraved grips priced at around $100. These are defined as an SOC, or Special Order Custom and are done through a separate department at the company that only handles this custom work. All orders must be placed over the phone, and as the work is done handgun by handgun. These orders take longer to fulfill, usually 3-4 weeks.

In addition to grips, the company offers other products such as knives, backpacks, and other aftermarket merchandise that is sold through the company. The knives are from “Zero Tolerance Combat Knives, which is a collaboration between Kai USA, Ken Onion, and Strider Knives to bring you a new series of professional-grade combat knives” as stated on the website. Backpacks are made by a company called Vertex Outdoors.

The original Kimber pistol before any modifications. These are also the original wood grips that came with it. As they are wood and have the full units crest upon them, the author wanted to take them off and save them because they are one of a kind.

The grips that the author ordered were for a unit commemorative Kimber Custom II 1911. The author’s unit, Bravo Company 1st Battalion 9th Marines had a special order placed from Kimber by around 50 Marines. The grips that came with the guns were wood and had the units crest engraved on them. Knowing that the gun was going to be actively used instead of becoming a safe queen, the author decided to replace the presentation wood grips with ones that could be handled in a rough manner but still wanted to keep the commemorative aspect of the handgun. Instead of going with the original unit crest, the author chose a Grim Reaper, which is the embodiment of the units motto, “The Walking Dead” originating from the Battalion’s reputation during the Vietnam War. On either side of the Reaper is the shortened form of the Battalions unit designation “1/9” with the dash marked as the sickle that the Reaper is holding. Note that the unit has been deactivated as of August 2014.

The back of the grips are marked “Special Order” to denote the SOC category of the grip order process. The frame is from Caspian. To the right is the original Kimber Custom II frame which the author didn’t use because it lacked front stippling and a rail.

As far as options went, the author chose a full size frame, standard thickness grip, beveled bottom, thumb notch, and a standard ambi safety cut. Besides all these options on the product page, there is a link to what each of these look like so a customer can’t get confused as to what they are. Some are obvious with the full size or compact options. Others have minute differences such as the Rock Island ambi safety cut or the extended STI ambi safety cut. For a texture, the author went with the slanted type and chose the MARSOC color scheme. It only seemed fitting considering the handgun was commemorating a Marine Infantry unit. G10 material was chosen as opposed to the Micarta.

This is the blueprint designed by the author for making the grips. All it is is the image from the VZ Grips website with a photoshop image of the desired engraving. The author highly recommends readers complete images such as these when sending in custom work because it leaves little to question from the maker and it gives the customer a good idea of what the finished product will actually look like.

After finalizing the order the author waited the estimated 3 weeks the grips were finished and sent out. Throughout the process, the staff at VZ Grips were very cooperative while the order was filled and were quick to reply to emails about its status. The grips came in a VZ Grips display carton and the author immediately put them on his 1911. The first observation about them was that they were extremely tight, a good thing considering that the 1911 is optimal when all the parts are fitted to each other. The one downside was that the left grip was a breadth too high and was pushing up on the Wilson Combat slide release. This might not have happened with the standard slide release that came with the 1911, but with the Wilson Combat one, the slide release was actually putting some serious pressure on the slide itself and thus severely hindered operation of the handgun. This wasn’t a problem as the author simply filed down the top of the grip just enough so the slide release could rest in its natural placement. The great thing about the grips in this case is that since the material is made from bonded silica, there were no after markings from the filing down, because the filing just took off the top layer of the material and it’s the same all the way through. After the filing, the handgun operated as designed. Readers should take note that if ordering grips for a 1911, some hand filing might be necessary when dealing with that slide release.

This shows the marks left by the grips being just a slight bit too high for the gun and thus pushing up on the slide release, which in turn was pushed down by the slide and thus created friction.

The Slant texture looked very odd from the online site but once the grips were installed on the pistol it felt extremely good, just enough smoothness to be gentle on the hand but just enough aggressive texture to get a good grip with gloves on. By looking at the picture, one would think that each individual chainlink is textured in that direction, but really it just slants through the grips with the texture embedded inside it.

Your Privacy Choices

Your Privacy Choices