This past July I was fortunate enough to tour the Sig Sauer Headquarters and manufacturing facilities in New Hampshire. Now most of you will immediately think of Exeter and you would be partially correct. Sig moved into the new facility, shown above, one year and four months ago. The Exeter facility is still in use by R&D as well as a few other functions based there. The new “Campus”, as Sig calls their facilities, is the base for the manufacturing of all weapons as well as the headquarters for all the executive staff and CEO.

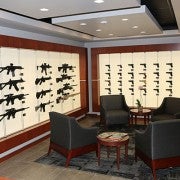

The new “Campus” is a beautiful modern structure and is very impressive when viewed from the front of the building. As one enters the main foyer the first thing you see is a large two story circular room with a receptionist desk and security station. This area is obviously meant to impress and it surely succeeds.

Looking to the right you see a larger meeting room shown below. Of course there are plenty of Sig rifles and pistols mounted on backlighted walls.

As you look down and left from the observation platform you’ll see a portion of the 72 CNC machines. All of the 72 machines are in use creating various basic shapes of handguns and rifles.

Just to the right of center is the assembly area then the indoor test range. On the farthest right side is a large storage area for parts with which the assemblers draw from during the day.

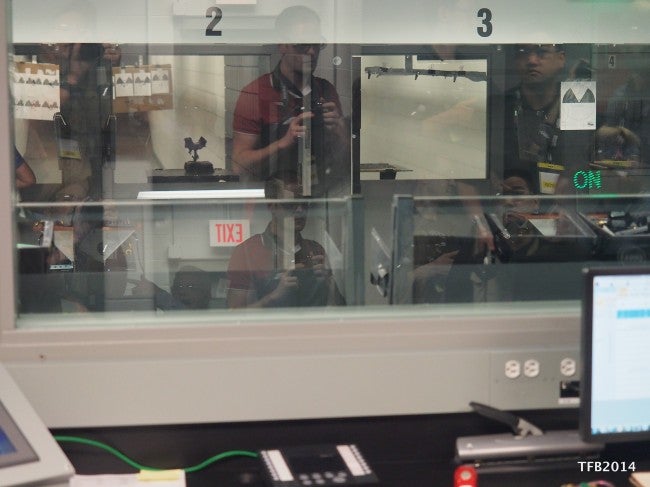

The indoor test range:

Entering the door to the fully enclosed range you step into a control room which is part security camera station while the rest of the station monitors the range lines as well as the environmental systems.

Each person shooting/testing these new pistols and rifles fire one magazine through each gun making sure they function and live up to the accuracy standards within that controlled environment. After two hours each shooter is rotated throughout the shift.

Here are other areas where sanded and buffed guns are then placed in vats for color or anodizing.

So after all of this work you get something that should look very familiar and a heck of a lot of them!

Gallery:

Your Privacy Choices

Your Privacy Choices