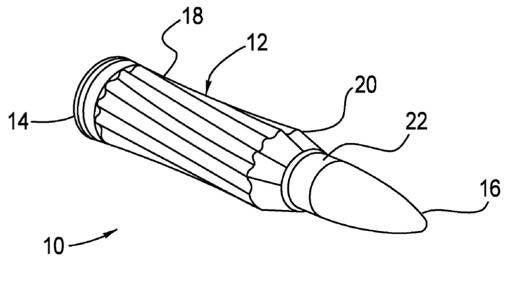

A patent application has recently been published for a novel cartridge case design. The inventor proposes a three part case with a metal base, spiraled polymer center and brass or plastic head.

The inventor claims that the spiraled case will reduce friction when extracting. I guess, in theory, the case would revert to its previous shape after being flattened by pressure during firing. The flutes would help reduce friction during extraction and reduce heat being transferred from the chamber wall to the plastic.

What this design does not address is one of the major advantages of brass cases. Heat from the gun and from the burning propellent is transferred into brass cases which are then ejected. Plastic cases cannot transfer this heat. To counteract this, some sort of heat sink would need to be added to the weapon. The reason plastic cases are only commonly used for shotgun shells is that because military firearms firing full-auto generate a lot of heat, the heat eventually builds up to a level that causes the cases to melt. Plastic then sticks to the chamber and causes reliability problems.

UPDATE: A photo of this case from a presentation given at National Small Arms Conference ’09 by Colt Defense and BML Tool & Mfg. Corp.

Thanks to Mark for the link.

Your Privacy Choices

Your Privacy Choices