Our friend Sebastian Unger (aka homegunsmithunger), inventor of the innovative “Topside Takedown 10/22 Receiver” has been working hard to find a manufacturing partner for his unique twist on a classic firearm design. In the middle of his prototyping phase, he has designed something equally unique: a 3D Printed Receiver for Ruger 10/22 style rimfire rifles.

Revolutionary Rimfire: 3D Printed Receiver For Ruger 10/22 Style Rifles

Unger’s polymer 10/22 receiver is fully functional, cycling .22LR rounds reliably. Still, there are a few caveats for interested builders, the main one being that his project is both experimental and dangerous. As for the rest of the details, I’ll leave you with Unger’s own words on his latest project.

I continue to be impressed with his innovative mindset.

Revolutionary Rimfire: 3D Printed Receiver For Ruger 10/22 Style Rifles

Revolutionary Rimfire: 3D Printed Receiver For Ruger 10/22 Style Rifles

Revolutionary Rimfire: 3D Printed Receiver For Ruger 10/22 Style Rifles

Revolutionary Rimfire: 3D Printed Receiver For Ruger 10/22 Style Rifles

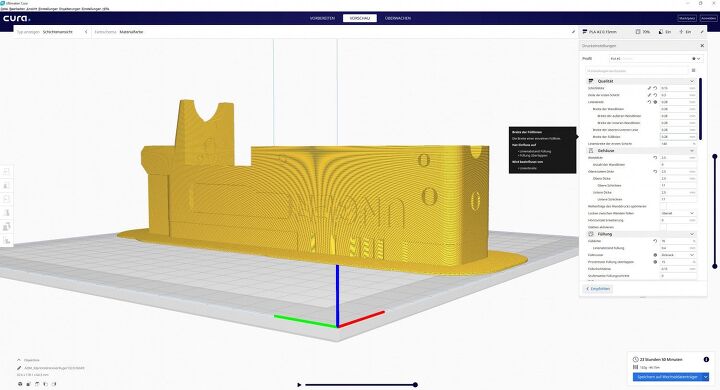

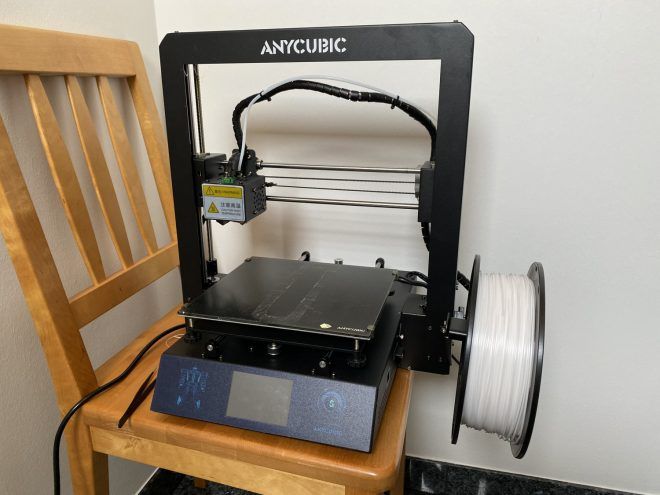

I have learned 3d design a few weeks ago for the topside takedown project to get the CNC prototypes done, therefore it was only a very small step to purchase a 3d printer and print a receiver for the Ruger 10/22.

The main reason for this test was my interest in seeing the true potential cheap 3d printed receivers, with the easiest printable material -> PLA. PLAs tensile strength is not so bad, but the impact resistance is low and temperatures above 60-70°C make it soft, so I have expected the receiver to fail early before I have tested it.

Surprisingly the receiver held up well, more than that, accuracy and precision was on a par with the metal receivers. I have printed the barrel bore a little bit smaller, heated up the barrel and pushed it by hand into the bore, so the bore had exactly the dimension of the barrel and the fit was ridiculous tight. I was very pleased with the result, because it was done with 0 effort, and it is for sure the main reason why this rifle shoots so well.

Reliability was not as good as with the metal receivers (5 FTF where I just had to push the bolt forward, during 500 rounds without cleaning, 4 of them at the end of the test). It could be improved by increasing the bolt play inside the receiver, but even the current result should be OK.

Longevity was satisfying, no functional problems for 500 rounds and just a small layer seperation in the magazine area, that can be easily fixed. If I would have added a radius in the corner where it happend, it would maybe not have been occured.

I want to mention a few things I did to give the receiver a higher chance to so survive:

– using an elastic buffer pin

– only using Topshot/CCI 40gr. standard ammo

– using a stock where the back end of the receiver is supported by the stock

– the barrel was not free floating, a free floating barrel would may have widened the barrel bore in the receiver as soon as it got hotThe biggest disadvantage of the receiver is for sure the lack of heat resistance because of the PLA, but with small improvements even affordable printers are capable of printing Polycarbonate, which is more heat resistant.

So overall I am very happy with the test, because it has proven, that sufficient receivers for semiautomatic .22 lr firearms are printable with affordable 3d printers. The material and energy costs for this receiver are approximately 5 Usd, it needed 135 gram PLA and took nearly 24 hours to print it.

Even with carbon fiber reinforced materials the print would not cost more then 15 Usd, and these receivers would come very close to the metal receivers in all points, so the performance in relation to the price is amazing in my opinion.

Alltough it worked out well for me, I have to point out that all of this is 100% experimental and dangerous, small changes (print settings, buffer, ammo….) or errors can cause bad injuries with these things, so I would not recommend to anyone doing this at home. This is one of the reasons why I will not upload the files. Laws are changing all the time too, so there is also a risk that uploading these things gets illegal some day.

Your Privacy Choices

Your Privacy Choices