The US Army Materiel Command has shared an interesting behind the scenes video filmed at the Anniston Army Depot in Alabama. Ever wonder what happens to the US Army’s tired small arms? All the M4s, M240s and M2 Heavy Machine Guns which have seen decades of service? Well many of them pass through Anniston Army Depot and receive a new lease of life.

The Anniston Depot near Bynum, Alabama covers 25 square miles and boasts a chemical weapons storage area, tracked vehicle repair plant, a huge munitions storage base and a state of the art 250,000 square foot Small Arms Overhaul facility. The Army Materiel Command’s video focuses on the small arms repair facility. It is presented by Anniston’s weapon’s division chief, Paul Barber, takes us through some of the Small Arms Overhaul facility’s processes.

Barber guides us through a small section of the 80,000 sq foot facility explaining how the technicians at Anniston disassemble, strip and refinish M4 components, service M249 SAWS and refurbish M2B .50 calibre heavy machine guns.

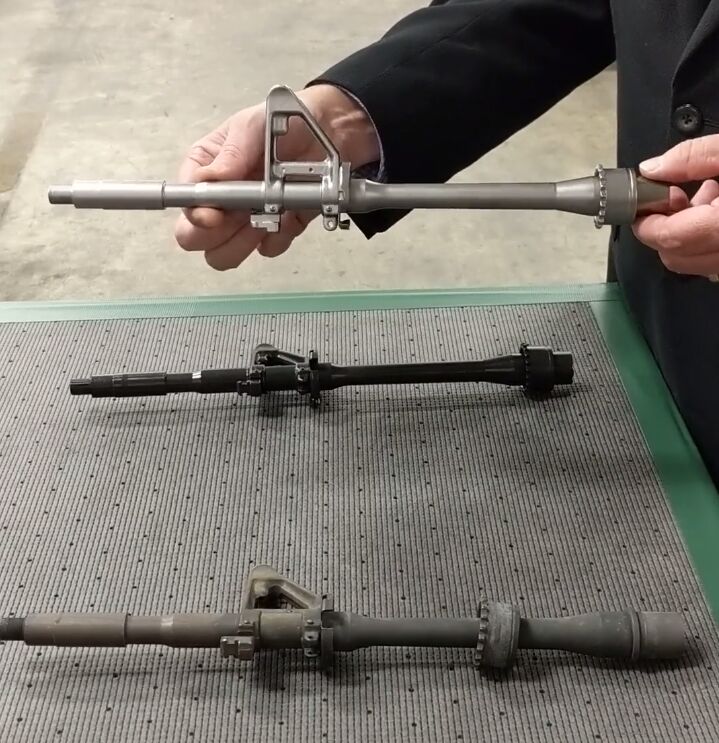

M4 barrels in various stages of servicing: barrel as it arrived as Anniston (bottom), after shot blasting down to bare steel (centre), refinished (top) (US Army Materiel Command)

Newly refurbished M4A1 Carbines in a custom rack (which holds 50 rifles) used to transport rifles. These will be tested at Anniston’s 100m indoor range, 10-rds are fired to check they group under 5 inches (US Army Materiel Command)

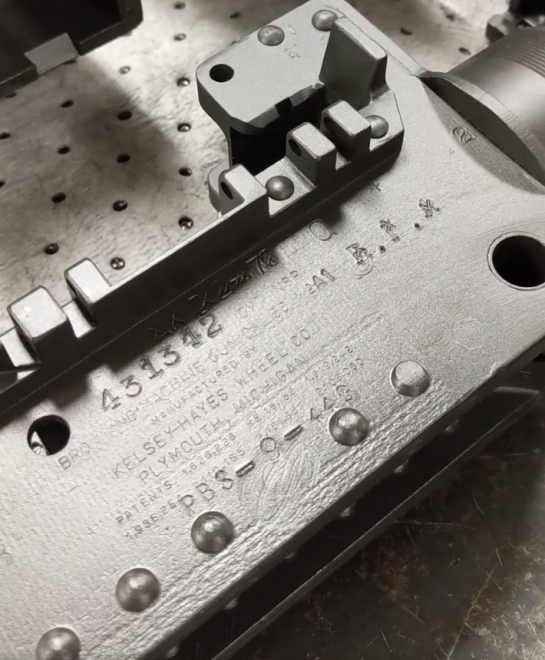

The video then shows a number of M2s being upgraded to M2A1 spec, with up to 60% of components recycled. Barber shows us a number of interesting M2 receivers and explains how Anniston Depot frequently sees weapons that are many decades old. Two M2s he points out were made during World War Two by manufacturers who only produced weapons for a short time. Barber shows us a couple of 75 year old examples one made by the Kelsey-Hayes Wheel Company and another by Frigidaire!

Close up of the receiver of a Kelsey-Hayes Wheel Company-made M2 (US Army Materiel Command)

The video finishes up showing how the M2 assemblies come together to build up a completed weapon before being put through an exerciser which cocks the weapon 700 times.

Anniston also disposes of small arms that are no longer serviceable, if during examination, repair and appraisal any firearm is deemed unusable or obsolete it is destroyed on site and the materials are melted down and sold for scrap.

Check out the video here

Your Privacy Choices

Your Privacy Choices