Profense LLC is a defense company that has its origins in the aerospace industry. Their primary interest is trying to introduce a next-generation 7.62x51mm NATO M134 Minigun. The company is doing this through two different strategies. First, they are actually manufacturing their own version of the M134 with several significant design differences from the currently fielded Dillion M134 that is in service all over the world. Second, they are actually offering upgrade kits for the GAU-2, GAU-17, MK44 or M134. These upgrade kits are called the M134 MUK, or Mission Upgrade Kit. If a Government user doesn’t want to purchase a complete fleet of new and improved M134 Miniguns, they can opt for the MUK kit as an upgrade to existing Miniguns.

TFB was able to get an exclusive view of the Profense M134 while at SHOT 2018, courtesy of the Profense staff then present at the show. The company was also generous enough to allow us to publish a promotional video on their Minigun, on our Youtube affiliate page- TFB-Side TV. The video is linked in the title above.

Visually the biggest identifying feature of the Profense M134 are the cooling fins on the front of the 6 barrels. These fins have been tested and the company says they provide a 25 percent reduction in heat when the machine gun is in operation. This system is patented and termed by Profense as the Aeroclamp.

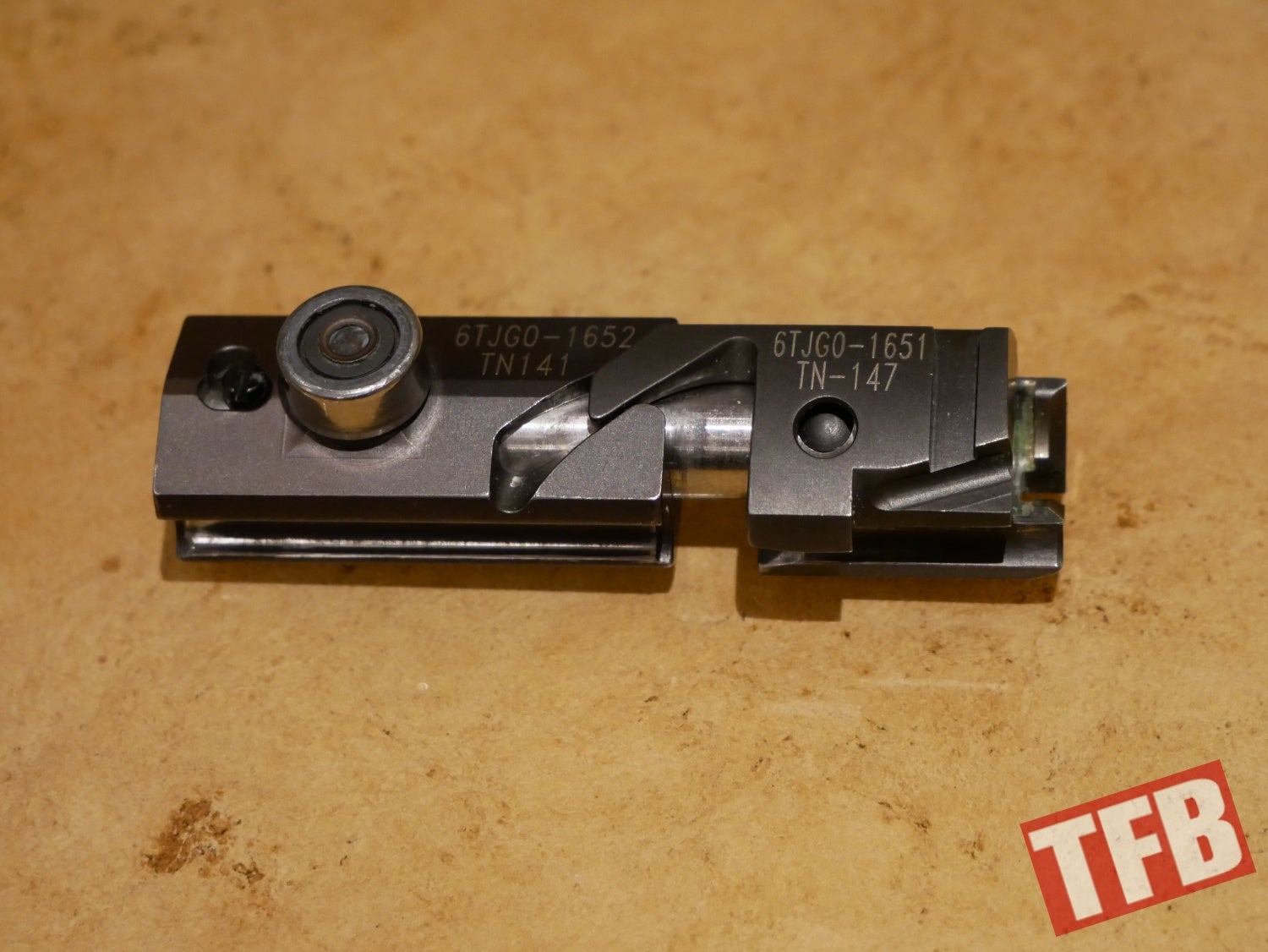

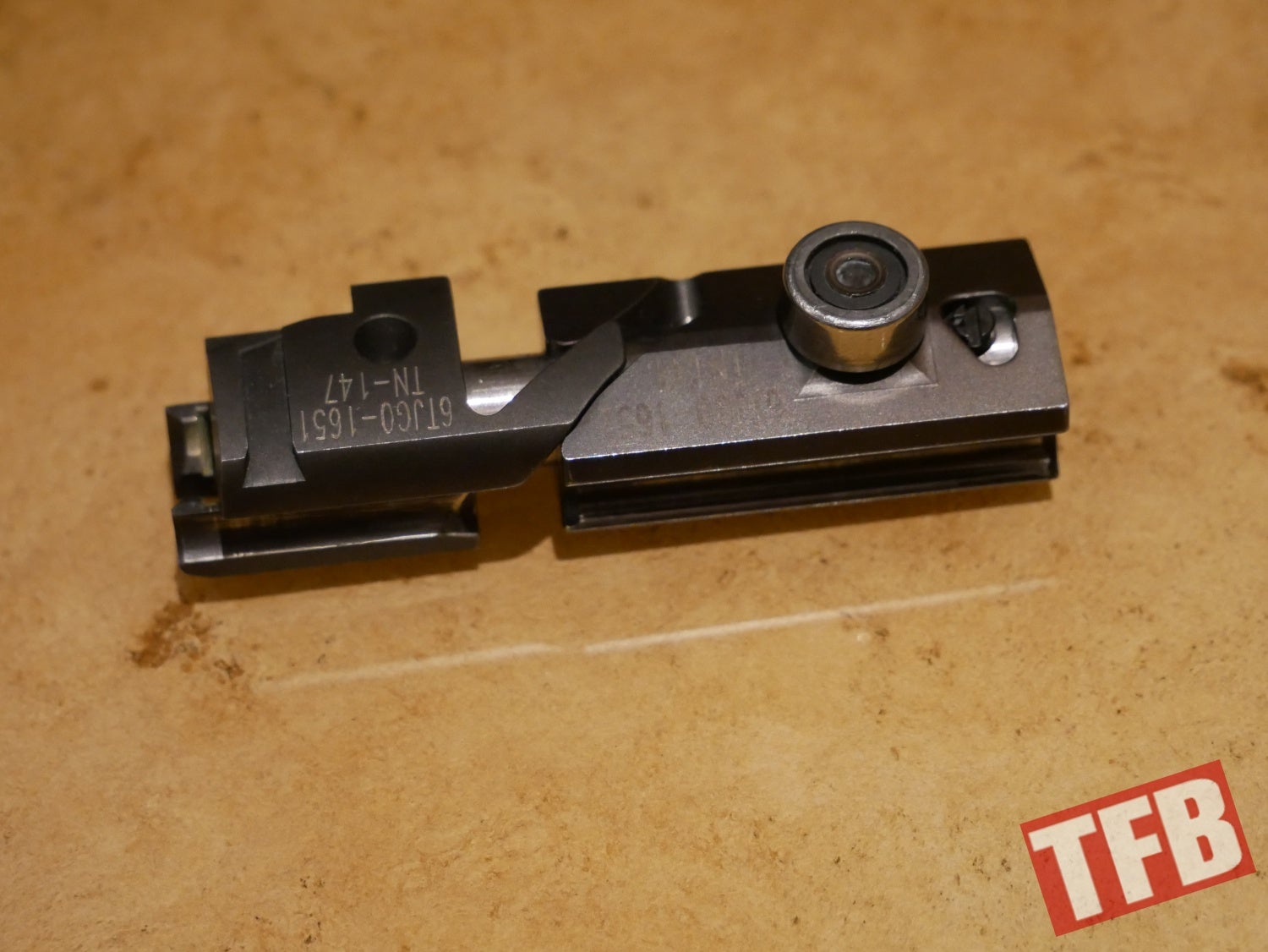

Profense mocked up this cartridge delinker to show the stark visualization of their version compared to the current Dilion M134. Dillion is on the left, Profense is on the right. In the Minigun’s internals, there would only be one of these in operation and only on a rod the size of half of the entire rod pictured.

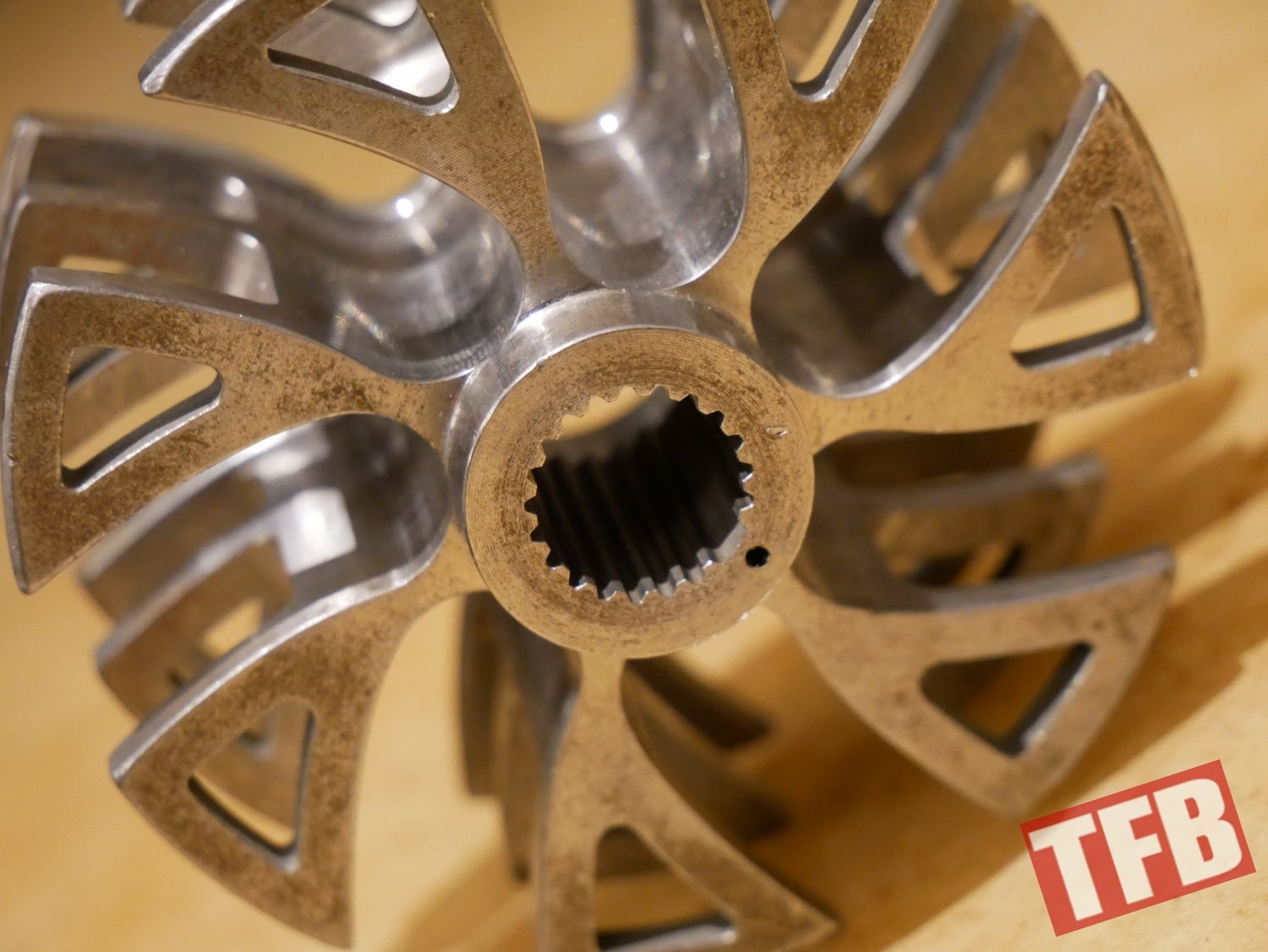

Notice who on the Dillion M134, the delinker relies on two holes (where a pin is placed into) cut into the rod on either side of it to “time” the sprocket to the rod. However on the Profense version, there is no need for a pin that could break or holes that could weaken due to the entire rod essentially becoming the “timing” piece by having “teeth” machined around the entire rod that index with corresponding teeth on the sprocket.

Legacy model left, Profense model right.

These are the bolts used in the Profense model. Six of these rotate with each barrel, all in different portions of the cycle of operations.

This GCU unit is designed to optimize the manual operation of the M134. The round counter lights up green, and can be switched off and on with the “Ammo” button at the lower left. This is so the counter doesn’t have to light up the inside of a helicopter during hours of darkness. The safety switch is underneath the red flip up shield, while the two fire control buttons/triggers are used for different rates of fire. 3,000 RPM on the right, 1,500 RPM on the left. If both are pressed at the same time, the 3,000 RPM setting is defaulted to. The lower round count can be useful in a training situation where ammunition consumption is necessary.

“Ammo Can Select” allows a user to program how many rounds are available from what was manually loaded into the Minigun.

“Ammo Boost” helps with sending electronic signals to the conveyer belt that is feeding the belt into the Minigun.

A neat add-on are the custom designed Hogue spade grips for the M134 grips. This addition stemmed from the previous grips on the Dillion M134 being made out of aluminum and certainly not comfortable on an extremely hot or cold day.

Your Privacy Choices

Your Privacy Choices