Product Release

In October, TFB’s Richard Johnson wrote a product release post illustrating Lyman’s GuardianGrip by Pachmayr. ICYMI, the GuardianGrip is a grip that allows for compact concealment, but when a button in the grip is pressed with the middle finger, a gate is swung down allowing for a full grip with the pinky finger.

Lyman GuardianGrip by Pachmayr

The comments were a reasonable mix of ‘cautious optimism’, as TFB readers such as Wow a completely new product that would actually be useful. And for a wheel gun. You would think we would have those completely figured out by now. Im genuinely impressed.” Others like reader Nathan Alred joked, “Press the button and it launches lint bunnies from your pocket all over the room.” ooks gimmicky, but I really want to give it a try.”

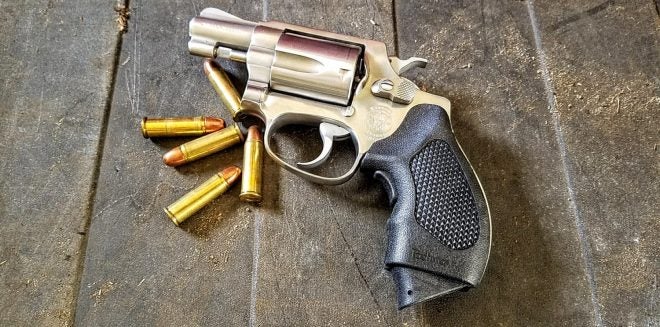

Seeing this, Lyman asked TFB if we wanted to formally review the grip and when TFB editors asked if I wanted to review the J-Frame novelty(l) I jumped at the opportunity because, full disclosure, my wife carries a S&W Model 60 J-Frame daily and if it helps her shoot, I want to know about it. She insists on carrying it due to the compact size and reasonableness of the recoil but she, like most TFB readers, has lamented the lack of a place for her pinky finger.

(l) Novelty can mean either “new, original, or unusual” or “a small and inexpensive toy or ornament”. We’ll find out which.

Primary Concerns

Like most TFB commenters, I had questions, and if Lyman and TFB were going to let me test it I wanted to make sure a few things got addressed on the range. Namely:

- Would I have to deliberately deploy the grip (as seen in the Lyman video), or could I forget about it with the same effect? And,

- If my grip and draw were hurried and sloppy, would my pinky finger prevent the deployment of the extension? Would this trip me up as I tried to readjust my grip?

These questions would in fact be answered on the range.

Arrival and First Impressions

The package arrived from Lyman in a small clear plastic pack with a sticker, a CD catalog, and instructions. I immediately began to play with the grips and cast away the instructions – which I would later discover was a mistake.

GuardianGrip Instructions

Instead, obviously, the first thing I wanted to do was take them apart. I wanted to see the spring plunger, the button, and the sear. I probably didn’t learn much, but did I enjoy geeking out a bit. While the two pieces shown below (and the push button/grip extension assembly) come out easily, the rest doesn’t fall apart and make a mess.

Inside the Guardian Grip, spacer and grip screw inserted.

Inside the GuardianGrip, spacer and grip screw not inserted.

Range Day Preparation

I had to wait a few days for range day, but about 20 minutes before driving to the range I took a flathead screwdriver and attempted to install the grips like any other pair of grips until, to my surprise, they didn’t fit right away. Now I had to find that instruction manual, and I was going to be late.

I discovered that the GuardianGrip requires you to remove the roll pin from the S&W frame that normally reinforces the stock grips. I carefully used a 3/32″ punch to do the job, but a 3/32″ roll pin punch would have been the better choice. It was range day though, and I wasn’t going to let that slow me down. After the roll pin was removed, the grips installed easily.

One (possible) detriment I should mention at this point is that the grips aren’t truly ambidextrous. Holding it in the right hand does feel better than holding it in the left, perhaps because I’m not a left-handed shooter, but also perhaps because the grip is designed to lay the thumb on the shelf. For one-in-ten of you, this might be a sticking point. Of course my left-handed wife shoots right-handed. Go figure.

Right Grip Panel

Onto the Range!

GuardianGrip shown closed and open for comparison.

My range partner that day was a friend and Federal Law Enforcement Officer. We fired the revolver single action, double action, strong hand only, and weak hand only – with the GuardianGrip, and with my original S&W Model 60 stock grip.

Shooting with the stock Model 60 grip with a very different feel. Not shown is the gap between the front strap and my fingers.

Drawing from the holster with the GuardianGrip. (That’s an undershirt, not my underpants, if you were wondering). Notice that the grip extension has already deployed.

Range Notes

My LEO friend and I had similar findings, and here are our notes from the range:

- Concern 1: There is no need to deliberately deploy the GuardianGrip – the sear is very sensitive and will deploy when you get anywhere near it. It isn’t like the Lyman video (posted below) in which the shooter reaches down, clicks the grip out, draws and fires. In real life, it all happens at once.

- Concern 2: When we drew, we often had our pinky finger below the grip preventing the GuardianGrip from deploying. This was very easily alleviated by bringing the pinky forward just a short distance and the strength of the spring will send the extension down. (I tried sophomorically to measure the distance with a micrometer and estimate the pinky needs to come forward about two tenths of an inch). While it does happen, I do not feel it was an issue.

- We both felt the strength of the spring was appropriate, which helped the above bullet point.

- We were both startled several times when the revolver went *click* during administrative handling. The kind of click that sounds like a dry-fire that COULD have been a negligent discharge. This was just the grip doing what it does – but it took some getting used to. If you press it, it will deploy. Whether you want it to or not.

- The grip is comfortable and fit both our hands well, and was much more comfortable than the stock grip.

- We both thought that felt recoil was much lower using the GuardianGrip than with my stock grip. The reason is no doubt due to increased control of the firearm, but the sensation of feeling less recoil was interesting to us both.

On the range with the GuardianGrip

A More Similar Comparison

When we got back to the house we took a few more pictures – this time with a size comparison to the Taurus, which my LEO friend sometimes carries. The difference between having the pinky extension and not having the pink extension really becomes noticeable at this point, and we regret not taking it to the range with us.

Size comparison, closed and open, of the two pocket-sized revolvers.

Interview Questions for Lyman

I’m not always satisfied with what I feel in my hands, what I see at the range, or the second opinions I get from (albeit well-informed) friends. As my own interests are well-aligned with design and engineering, I have a great deal of respect for the designers and engineers who make the hard decisions when developing products like this. I wanted to talk to whomever was responsible for, well, the design and the engineering. I proposed several questions to Lyman, and they provided me with some great answers:

TFB: What type of polymer is used? (Is it different from competitor polymers, or was a specific type chosen for a reason?)

Lyman: It is a specialty high-impact glass-filled nylon, which is often used in polymer magazines. In that application, it is important that the feed lips do not take a set over time when the magazine is stored loaded. Similarly, in this application it is important that the grip does not take a set over time from the pressure of the grip screw, resulting in it becoming loose on the revolver frame. Often when you stiffen a polymer by adding fiberglass strands, it becomes brittle. What makes this family of material special is that it remains incredibly tough.

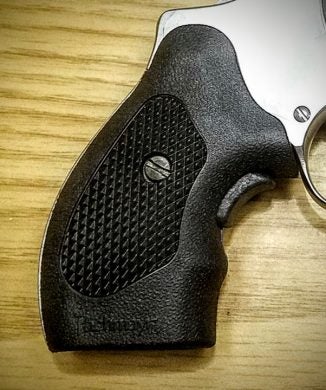

TFB: What was the design inspiration for the grips (there appears to be an M16A2-style diamond checkering, was this intentional?)

The overall size and shape of the grip when in the conceal mode (i.e. extension retracted) was inspired by old school two-finger boot grips preferred by police officers on their deeply concealed back up guns. The geometry of the extension was influenced by both three-finger revolver grips, and extended magazine floor plates on modern pocket sized pistols. As far as the checkering, it is intended to invoke a familiarity with classic checkered wooden revolver grips but wood naturally rounds slightly preventing the grip from being too sharp. With molded plastic, the checkering was intentionally rounded slightly to not be sharp in the hand or grab on clothing, while still providing a great grip.

P.S. – Someone has a great eye, as an older M16 grip was one of the reference designs measured during research on molding in checkering.TFB: Is there any patent information or development history we can share with our readers (is there anyone influential we can mention in the development history?)

Probably the most influential person during the development was a retired special agent from a federal agency who carried J-Frames as a backup for much of his career. He acted as the “true north” to make sure the design intent didn’t drift off track, was very excited about a functional accessory for such a barebones platform, and even provided older firearms to measure to make sure there was good backwards compatibility. Several patents have been granted on the design, with at least one more pending.

TFB: What kind of testing and evaluation was done to the product (did you melt any, freeze any, take a sledge hammer to any?)

We have been incredibly impressed by the strength and cold impact performance of the polymer resin used. Nylons in general are great with heat and chemical resistance. In this particular case, impact testing was done to verify that the material was performing as expected, as well as, testing on the pull out strength of the threaded insert/escutcheon and cyclic testing on the extension and release system. The metal components are made from materials commonly used in other firearm products. It was tested with lots of 38 and 38+P, but was also tested with 357 on a J-Frame with a scandium frame and titanium cylinder as a worst case scenario on recoil impulse.

TFB: Can you share how many prototypes/iterations you went through before coming up with a final design, and perhaps what changed in development?

It took four mechanism architectures to arrive at the current solution, which is pretty simple (for example, a single spring both pushing out the extension and resets the release button). It is actually quite easy to make a design more complicated, but much harder to make it simple. Once the architecture was selected, there were at least 46 iterations in CAD including five different prototypes along the way. Once tooling was created, it was refined five times to get it to match the design intent as closely as possible.

While I appreciate the ‘great eye’ compliment, I carried an M16A2 in the infantry. As they say, “to a hammer every problem is a nail”, and I suppose to me, every diamond checkering looks like an M16A2. And where Lyman states “It is actually quite easy to make a design more complicated, but much harder to make it simple”, boy isn’t that the truth.

I can also corroborate what Lyman stated with older J-frames and the grip’s fit. On my wife’s (1980s-ish) Model 60, the grips don’t fit perfectly for obvious reasons, but I found no functionality issue here. While there are slight gaps or overages, the grips were tight and the spacer they designed did its job well.

Slight gaps are seen this Model 60, but the fit is functionally excellent.

The GuardianGrip is available on Lyman’s website for $49.98.

Your Privacy Choices

Your Privacy Choices