In the coming decades, it is likely that one of the biggest challenges facing small arms ammunition designers will be solving the problem of how to deal with advanced body armors. The problem is already percolating to the surface, as Level IV body armor – which is immune to virtually all general issue rounds below .50 caliber – becomes more available and less expensive. Already, an individual can equip themselves with a full set of Level IV plates and a carrier for less than $1,000. As armor improves, it will only get lighter, cheaper, and more resistant to fire.

A US Marine corporal holds out the plate that saved his life. Modern rifle plates are lifesaving equipment for US servicemen, but they will increasingly find their way into the hands of our enemies as they become cheaper and more available. Image credit: United States Marine Corps, public domain.

We must then consider the possibilities for defeating sophisticated armors with small arms rounds. Up front, I should say: The prospects do not look good. The power and penetrating ability of small arms ammunition is limited by the practicalities of war. A round that is too large may defeat body armor, but will certainly put soldiers at a disadvantage against unarmored fighters with smaller caliber weapons that are capable of putting out a volume of fire many times higher. This, plus the size and weight of the weapons needed to fire larger-caliber rounds that can penetrate Level IV means there is a limit to how powerful an infantry weapon can be. First, however, some background is needed.

To understand why the prescence of Level IV and equivalent armors is so concerning to small arms ammunition designers, we must first review what it is that “Level IV” means. According to NIJ Standard-0101.05:

2.5 Type IV (Armor Piercing Rifle)

Type IV hard armor or plate inserts shall be tested in a conditioned state with .30 caliber armor piercing (AP) bullets (U.S. Military designation M2 AP) with a specified mass of 10.8 g (166 gr) and a velocity of 878 m/s ± 9.1 m/s (2880 ft/s ± 30 ft/s).

Type IV flexible armor shall be tested in both the “as new” state and the conditioned state with .30 caliber AP bullets (U.S. Military designation M2 AP) with a specified mass of 10.8 g (166 gr) and a velocity of 878 m/s ± 9.1 m/s (2880 ft/s ± 30 ft/s).

For a Type IV hard armor or plate insert that will be tested as an in conjunction design, the flexible armor shall be tested in accordance with this standard and found compliant as a stand-alone armor at its specified threat level. The combination of the flexible armor and hard armor/plate shall then be tested as a system and found to provide protection at the system’s specified threat level. NIJ-approved hard armors and plate inserts must be clearly labeled as providing ballistic protection only when worn in conjunction with the NIJ-approved flexible armor system with which they were tested.

In conjunction with this, we should observe four things: First, that the .30 cal. M2 Armor Piercing projectile is a very sound design utilizing a relatively high quality manganese-molybdenum steel core hardened to 785 Vickers, which also includes a lead cap which further improves penetration characteristics. This construction allows it to penetrate over 10.6mm deep into a 22.2mm RHA steel plate at a distance of 91 meters. Second, we should note that the tests use a velocity 105 ft/s higher than the M2 AP’s specification – 2,880 ft/s instead of 2,775 ft/s. This is to account for velocity shift due to high temperatures and other factors which could cause a round to penetrate a plate that would normally be rated to stop it. Third, we observe that no common steel-cored armor piercing small arms ammunition below .50 caliber exceeds the penetrative ability of .30 M2 AP by a significant enough margin to defeat Level IV at combat ranges. The other two most significant steel-cored AP rounds in use are the Russian 7.62x54mmR B-32 Armor Piercing Incendiary, and 7.62x51mm NATO M61 Armor Piercing, neither of which exceeds the .30 M2 Ball in penetrative ability. Fourth, Russian GOST Class 6a armor is equivalent to NIJ Level IV armor, it being proof against three shots of B-32 API at no more than 10 meters distance.

This means, in short:

Point 1: Current Level IV and GOST Class 6a armors are *BY DEFINITION* immune to all current steel-cored armor piercing rounds of caliber .30 and below, at all ranges.

Therefore, we should investigate the potential of rounds with cores other than steel. Chief among these materials are tungsten alloys, more specifically different tungsten carbide. Undoubtedly, tungsten carbide cored rounds are effective – tungsten cored 5.56mm M995 penetrates 12mm of RHA at 100 meters, more than .30 M2 AP. However, they have a fatal flaw, and that is materials consumption. To explain, we will need an example. Current 7.62mm M993 has a penetrator weight of 5.9 grams, but it is not ballistically optimized and slows down quickly due to its flat-based bullet. On the other hand, 5.56mm M995 has a penetrator weight of approximately 2 grams, and it is known that RMA’s 1199 Level IV plate will stop M995 at about 2,900 ft/s, which is representative of a striking range of a little less than 100 meters. Therefore, in this example, we will take a round with an intermediate weight penetrator. If we assume a low drag projectile of 6.5mm diameter and 7 grams (108 grains) weight, then a penetrating core appropriate for that projectile would weigh approximately 5.06 grams. Since the core is 84% tungsten, it consumes 4.25 grams of tungsten per shot. From this, we need to figure out what kind of a liability the tungsten core will be in an economically taxing situation, such as a protracted war. To understand this problem, we need to know two things: One, global production of tungsten and its sources; and two, expected ammunition consumption per year.

For the latter, we first understand that Army requirements for ammunition production have a baseline of approximately one billion rounds per year. During a protracted insurgency, this quantity can be expected to rise to 2-2.5 billion rounds per year. During a global conflict against peer nations, ammunition consumption can be expected to equal the consumption during World War II, which was close to 22 billion rounds per year. In this example, we will simulate a protracted counter-insurgency type conflict.

Unfortunately for those seeking tungsten as a solution, 85-90% of global tungsten production originates in the People’s Republic of China. In contrast, while the USA mines virtually no tungsten, it consumes tungsten equal to 23% of global annual output, 60-70% of which is taken directly from global output (15% of global output per annum). As of 2011, the US had 140,000 tonnes of tungsten reserves, and consumed about 18,200 tonnes from all sources.

In the event of a proxy war, ammunition requirements would rise from the one billion per year figure. In 2005 (before the “Surge”), the US consumed over 1.7 billion rounds. It’s reasonable to assume that any new proxy war will consume comparable or even greater amounts of ammunition. We can estimate based on a few consumption levels:

1.5 billion rounds per annum: 6,375 t/yr

2.5 billion rounds per annum: 10,625 t/yr

7 billion rounds per annum: 29,750 t/yr

Scenario: In 2031, the US and PRC enter into a proxy war in Africa, in which the PRC distributes Level IV body armor to insurgent forces. The US had previously decided to issue as standard a tungsten round, despite the materials supply problems. It’s a 6.5mm round with a penetrator that uses 4.25 grams of tungsten. The Chinese stop exporting tungsten to the US to add pressure to them. The math then looks like this:

2031: The US possesses 140,000 tonnes of tungsten plus 60,000 tonnes in recent imports. Total tungsten 200,000 tonnes. The initial ammunition consumption in the first year of war rises to 1.5 billion rounds, and eats 500 million rounds out of stockpiles, consuming 4,250 tonnes of tungsten from newly manufactured ammunition. US manufacturing also accelerates, increasing consumption from machining and production to 60,000 tonnes per year. By the end of 2031, the US has 135,750 tonnes in reserve. A program is begun to reclaim tungsten used in manufacturing.

2032: 135,750 tonnes in reserve. A trickle of tungsten from South America and Russia adds 10,000 tonnes of tungsten to reserves. The reclamation program generates an additional 5,000 tonnes. Total tungsten 150,750 tonnes. Ammunition consumption continues to rise to to 2 billion rounds, and eats 750 million rounds out of stockpiles, consuming 5,313 tonnes of tungsten from newly manufactured ammunition. 60,000 additional tonnes are consumed in manufacturing (page 7).

2033: 85,437 tonnes in reserve. 10,000 in additional imports as the US buys up virtually every tonne of non-PRC tungsten produced. Reclamation program generates an additional 10,000 tonnes as its efficiency improves. Total tungsten 105,437. Ammunition consumption continues to rise to to 2.5 billion rounds, while ammunition stockpile consumption is throttled to 500 million rounds as stockpiles shrink. Ammunition production consumes 8,500 tonnes of tungsten. 60,000 additional tonnes are consumed in manufacturing.

2034: 36,937 tonnes in reserve. 10,000 in additional imports. Reclamation generates 15,000 tonnes. Total tungsten is 61,937. US use of tungsten in manufacturing must be throttled, and at this point they can no longer afford to use tungsten cores in small arms ammunition.

It takes a mere three years for the US to run dry on tungsten to the degree that tungsten-cored ammunition is no longer viable. Now they are in a protracted proxy war against insurgent enemies which are equipped with body armor, and their small arms ammunition standard is incapable of dealing with this threat without tungsten cores because of how it was initially configured. Given that the US is currently engaged in a counter-insurgent conflict that has lasted over fifteen years, this timeline can be considered untenable for this scenario.

Therefore:

Point 2: Tungsten is not a viable core material for standard issue small arms ammunition. It can ONLY be used for specialist purposes, e.g. SOCOM.

If steel-cored ammunition of reasonable size will not penetrate the armor, and if tungsten-cored rounds are not economically viable even for a counter-insurgency conflict, then question then becomes “how is it possible to counter Level IV armor with small arms ammunition?” There are a handful of potential answers to this question. First, we should consider solutions to this problem that are already organic to the infantry squads. 40mm grenades, medium and heavy machine guns, and other supporting weaponry offer a potential counter to Level IV armor and its successors. Medium (mounted) machine guns offer the capability to defeat advanced armors through multiple strikes of armor piercing ammunition, grenade launchers (which are currently integrated at squad level) can bypass armor with shrapnel, and heavy machine guns can defeat it outright. Which is to say:

Point 3: Before any advanced anti-armor small arms solutions are implemented, it would be potentially very advantageous to explore and develop the use of already fielded weapons as counters to enemy heavy personal armor.

This step could lead to inexpensive and organic solutions, such as developing new tactics for countering armored troops, and fielding more of the types of weapons found effective (e.g., adding more 40mm grenade launchers to the rifle squad).

The major downside to this approach is that it still does not provide the Infantry with a rifle round that is capable of penetrating heavy body armor to any substantial distance. Given a prohibition against tungsten-cored ammunition for this application, other solutions must be considered. To find these, we turn to the history of tank ammunition development, and we find three possible kinetic energy solutions:

- High velocity armor piercing (HVAP), which uses a high muzzle velocity (1,000 m/s [3,280 ft/s] or higher) and a hardened metallic core for maximum penetration.

- Armor piercing discarding sabot (APDS) which uses a sabot to improve the swept volume of the round, thereby maximizing the efficiency of energy extraction from the propellant to achieve even higher muzzle velocities (1,100 m/s [3,600 ft/s] or higher)

- Armor piercing fin stabilized discarding sabot (APFSDS), which uses a sabot like APDS, but marries that to a long, thin flechette for maximum energy retention through the air and striking energy concentration in the armor plate. APFSDS typically produces even higher muzzle velocities (1,500 m/s [4,900 ft/s] or higher)

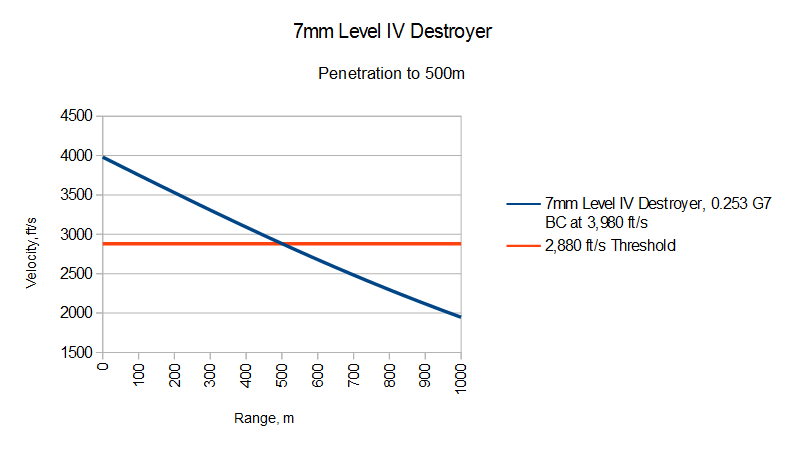

Fortunately, we can easily evaluate the practicability of two of these solutions: HVAP and APDS, with one simple example. First, we will turn back to the M2 AP projectile, by which Level IV armor is defined. We know that this projectile will be stopped at a muzzle velocity of 2,880. Since this limit is definitory, we can assume that an M2 AP projectile impacting above this threshold will have at least a chance to penetrate. From this information it is possible to make a graph which tells us what the initial performance of the projectile must be to give a desired effective range against a Level IV plate. In this case, I will make an assumption that 500 meters of effective range is desired. Also, the M2 AP projectile itself is not aerodynamically streamlined according to modern methods. It is possible to produce a more streamlined projectile which houses a similar or identical armor piercing core, which will give us energy retention:

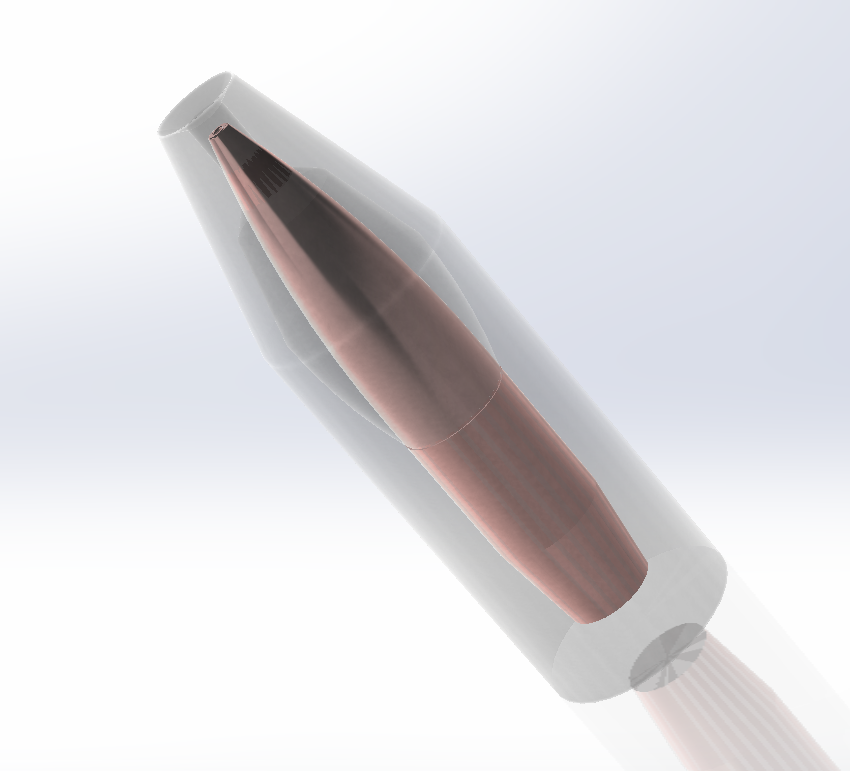

A 7mm low-drag bullet, with a steel armor piercing core similar in dimensions to that of .30 M2 AP. Estimates indicate this projectile shape would have an 0.938 i7 Form Factor, which would give a G7 ballistic coefficient of 0.253 with its weight of 134 grains (8.69 g).

Now, using a threshold of 2,880 ft/s striking velocity for effect against Level IV, we can determine what the required muzzle velocity of the round would need to be for a 500 meter effective range:

We now see that with this projectile, a 3,980 ft/s muzzle velocity is needed, which means a required muzzle energy of nearly 6,400 Joules! The question now is, is this practical with either HVAP or APDS? The first is answered easily: No. The muzzle energy required for even a 500m effective range with a conventional necked down case and bore riding bullet is 30% higher than even the 7mm RUM, which is itself already at or beyond the point of diminishing returns for case volume. 30% more muzzle energy than that round with a 7mm projectile is likely impossible with conventional or even foreseeable small arms ammunition technology, to say nothing of practical.

However, APDS routes around this problem by de-coupling the bore diameter and projectile diameter via use of a discarding sabot. First, we must determine the size and weight of a potential sabot, which we can do through a simple model:

A .510 caliber nylon sabot designed for the 7mm AP projectile shown above. The sabot’s weight alone is 4.3 grams (66 gr), more than a 5.56mm projectile.

Due to the added weight of the sabot to the projectile, the round now needs to produce a muzzle energy of just over 9,560 J to meet the 500 meter velocity threshold – a considerable increase. The good news is that not only is an energy level of almost 10,000 Joules possible with a .510 caliber round, an off-the-shelf caliber already exists that is capable of those energy levels: The .500 Jeffery dangerous game hunting round.

The APDS configuration does offer a possible solution, therefore. Is it practical? It is certainly feasible, but the size and weight of the round needed to make it happen seem excessive. It is possible that the design shown here is not as efficient as it could be, in one way or another. However, it appears representative of the general class of round needed to produce the the desired 500 meter performance – and it is larger than, and as heavy as .338 Lapua Magnum!

The .50/7mm APDS round, flanked by 5.56mm (left) and 7.62mm (right). The sheer size of round needed to provide a 500 meter effective range against Level IV armor, even with a discarding sabot design, seems excessive.

Then, we are left with the option of an armor-piercing, fin-stabilized, discarding sabot (APFSDS) round. And here, my predictive ability ends. I do not have the tools to evaluate the APFSDS concept adequately. My ballistic calculator will not accept velocity values high enough, I do not have a good drag model for a flechette or dart shape, and I do not know what a good threshold penetration velocity looks like for such a projectile. However, there are some things we do know. First, it is very likely that the high sectional density dart shape will penetrate armor better than the steel core of .30 M2 AP, which would mean a lower velocity threshold and a correspondingly lower required muzzle energy. Second, flechettes experience far less aerodynamic drag than conventional projectiles, due to their very high length to diameter ratio (L/D) and also their aforementioned high sectional density. This means they typically hold onto velocity much better than conventional bullets, which would also substantially reduce the necessarily muzzle velocity to produce the desired target effect at range. However, a small arms flechette round designed to penetrate Level IV armor from a considerable distance would still likely have to be fairly large and high energy. Whether this could be accomplished with 5,000 J, 4,000 J, 3,000 J or some other value is impossible for me to tell, but it is highly unlikely that such a round could be made that was compatible with existing 5.56mm weapons, and probably 7.62mm weapons as well.

To sum up:

Point 1: Current Level IV and GOST Class 6a armors are *BY DEFINITION* immune to all current steel-cored armor piercing rounds of caliber .30 and below, at all ranges.

Point 2: Tungsten is not a viable core material for standard issue small arms ammunition. It can ONLY be used for specialist purposes, e.g. SOCOM.

Point 3: Before any advanced anti-armor small arms solutions are implemented, it would be potentially very advantageous to explore and develop the use of already fielded weapons as counters to enemy heavy personal armor.

and,

Point 4: A conventional steel-cored HVAP small caliber round that can defeat Level IV out to combat distances (i.e., 500 meters) is virtually impossible to create. Only medium (e.g. .338) and high (.50) caliber rounds of conventional design can produce this effect. Likewise, a steel-cored APDS round designed to defeat Level IV to these distances would have to be so massive that it would be practically medium caliber ammunition anyway. Only APFSDS offers the possibility of Level IV armor defeat out to medium ranges with steel cored projectiles, at a size and weight comparable to current small arms ammunition (5.56mm and 7.62mm).

Your Privacy Choices

Your Privacy Choices