Solving the failed extraction detraction:

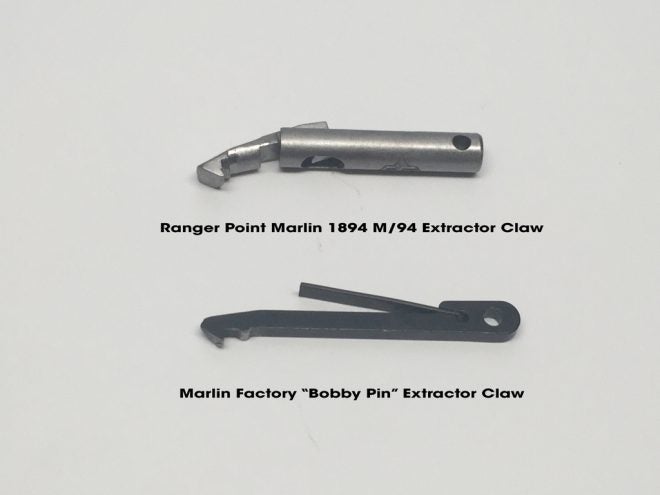

Recently, Houston, TX’s Ranger Point Precision reached out to me about a product they had been diligently developing for some time: an upgraded extractor claw for the Marlin 1894. The original Marlin 1894 extractor looks like a bobby pin, and works just about as well. Besides poorly made levers, the original extractor was the main cause of the “hitchy” feeling many 1894s have during the cycling of the action. Another side effect of the old extractors is they can fail entirely to extract cases. RPP’s new extractor fixes these problems with a whole new design. Filling the extractor channel completely, with an integral compression coil spring, these new extractors engage far more of the cartridge rim, and make cycling the action far faster, smoother and more reliable.

Designing the small part was no small task. Per RPP:

(RPP) worked for more than 6 months to get the extractors designed and tuned to work right. And thanks to Marlin changing the 1894’s bolt design 5x, (RPP) also had to design five different extractor claws – plus a 6th that we use in our semi-auto pistol caliber short stroke carbines.

The end result is an excellently executed part that seriously upgrades performance. Here are the specs:

FEATURES– Machined from super strength 4340 steel alloy (far thicker and stronger than the factory part) and nickel plated for incredible strength and corrosion resistance.– Closely held CNC machine tolerances eliminate extraneous movement and ensure consistent fit and function– Compression coil spring improves extractor claw compliance during feeding, lowers cycling effort, and greatly increases service life (virtually unlimited lifetime)– Robust dimensions and superb geometry ensure no case gets left behind– Rigorous testing by SASS Cowboy Action Shooters, Marlin Enthusiasts / Machinists– Drop-in part that installs in minutes (comes with one extractor claw/shaft/spring, one punch, one replacement spring if original is lost)– Marlin 1894, Marlin 1894CB and Marlin 1894CL options (fits all calibers: .218 Bee, .25-20 Winchester, .32-20 Winchester, .32 H&R Magnum,. 327 Federal, .38 Special, .357 Magnum, .41 Magnum, .44-40 Winchester, .44 Special, .44 Magnum, .45 Colt)

Ordering and Installation:

Images courtesy of RPP

Author’s Disclosure: Ranger Point Precision was kind enough to ask me to be an initial product tester for their extractor claw.

RPP had me inspect my 1894 bolt before sending the part, due to the aforementioned issue of Marlin changing the location of the extractor claw channel in the bolt. I required option #2. The part arrived promptly. I was impressed that along with the part, they send a pin punch! This ended up being a critical item, as I broke my old punch loosening the extractor retention pin, which can be extremely tight in 1894 bolts. RPP also provides a very easy to follow installation video for customers without previous gunsmithing experience. The provision of the tool necessary for installation along with the detailed instruction video was much appreciated. I hope more companies go this route in the future, and good on RPP for doing so.

Old extractor

New Extractor-note the massively increased engagement surface

Image courtesy of RPP

When laid side by side, there is no contest between the old flat spring vs the new RPP extractor. wider, smoothly machined, and nickel plated, and imparting little friction resistance to the cycling process, RPP’s extractor looks alien to the rest of my 1894’s spartan construction. In a decidedly good way. Installation took only 5 minutes start to finish. I should add that RPP also provides an extra coil spring, should the one provided take off inadvertently during installation. I’m sure many future customers will appreciate this extra consideration.

Everything included: Pin punch, Extractor Claw assembly, extra spring. (Image courtesy of RPP)

I tested the extractor, reinstalled the bolt, and then cycled the action with a few dummy round to make sure everything was working well. Cycling the action immediately felt much smoother; it was time to test the extractor for real at the range.

Performance at the Range

I shot my 1894 with the new extractor through about 50 rounds of .44 magnum and .44 S&W Special the next day, with nickel and brass cased ammo from Hornady, Cor-Bon, Buffalo Bore, Winchester, and Federal. Cycling the action for the first time after firing was so smooth, I was almost incredulous. I had to look and see if the first case extracted, as I was used to far more resistance cycling the action after firing a round. Sure enough, everything had functioned perfectly, I just needed to get used to not feeling the two hitches in the action from the old extractor. From then on, my range session was a blast, and I had fun seeing how fast I could cycle the action after each shot. I used to have to be very precise how I worked the lever with the old extractor, as to prevent malfunctions. This is no longer an issue with my rifle. Ejection was also incredibly consistent, with a neat pile at the 2 o’clock position.

Not a single case escaped the clutches of RPP’s new claw!

Overall Impressions:

RPP has hit the bullseye again with their new extractor claw. Like their medium loop lever, the addition of new claw resulted in a vast improvement in function of my carbine. I would say that it is well worth its value at $58.00, and feels like an action job has been performed with the replacement of one crucial part. I will have a lot more confidence in my carbine the next time a pack of wild boar comes boiling out of the bushes, and can’t wait to go get more sausage for the freezer with my new extractor installed. If one has a Marlin 1894 and uses it regularly, this new extractor is worth every penny. For more information or to order, please visit Ranger Point Precision.

A huge thank you to Ranger Point Precision! I should add that though they are located in Houston, their employees and facilities survived Hurricane Harvey, and they are back at work and ready to provide customers with quality parts and service. I would encourage any of our readership that can donate to a reputable organization that helps in Hurricane recovery to do so, and wish any of our readers in hurricane impacted areas safe passage and recovery through these tough times.

Your Privacy Choices

Your Privacy Choices