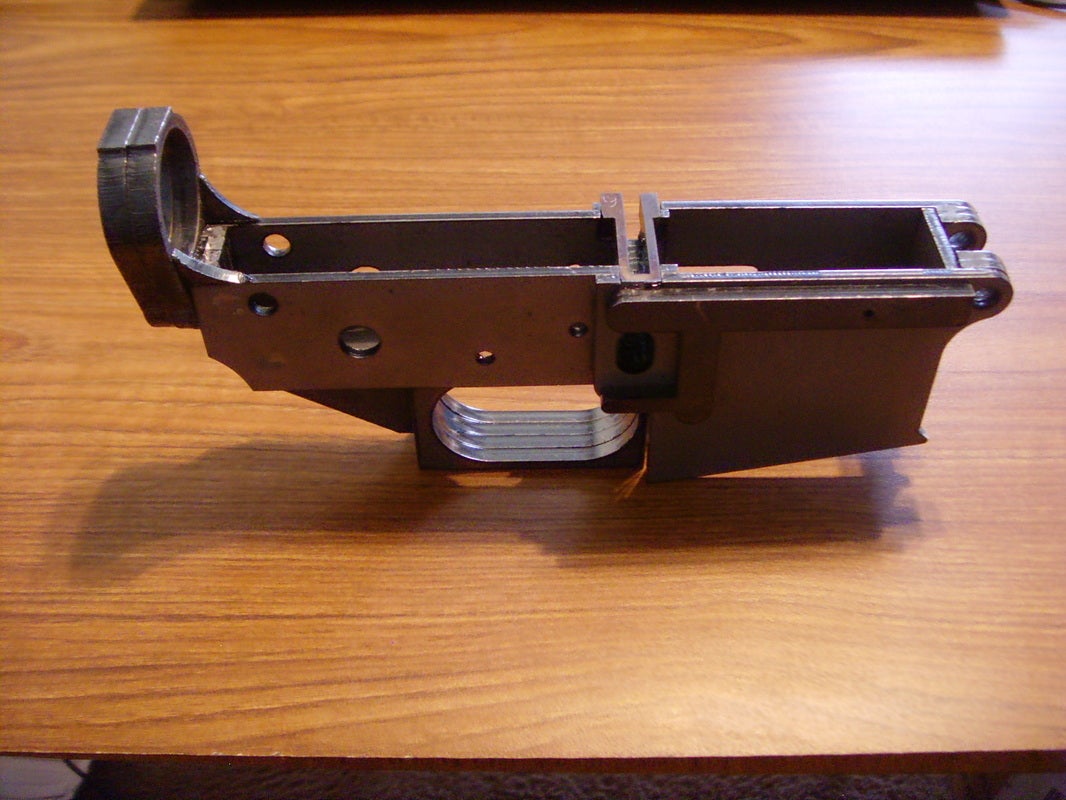

Beyond legos for gun nerds comes this soon-to-be-AR15-lower (aka package of raw metal) that can be transformed with skill and welding. Designed and machined by The Flat Spot, this assortment of metal is what I have dubbed a 25% lower receiver. Whereas 80% lower kits only require a drill press and finishing, this flat set requires welding and tapping of the receiver extension hole.

Practical in the days where complete lowers can be had for $30? Probably not. However this kit looks like a lot of fun for a dedicated builder. Sure, it will end up heavy, less polished and less than milspec, but you were the one who actually brought it to life. And government, serial numbers, NICS checks, Molon Labe, yada-yada-yada stuff too.

The Flat Spot AR-15 RECEIVER FLAT – WELDABLE- $28.99

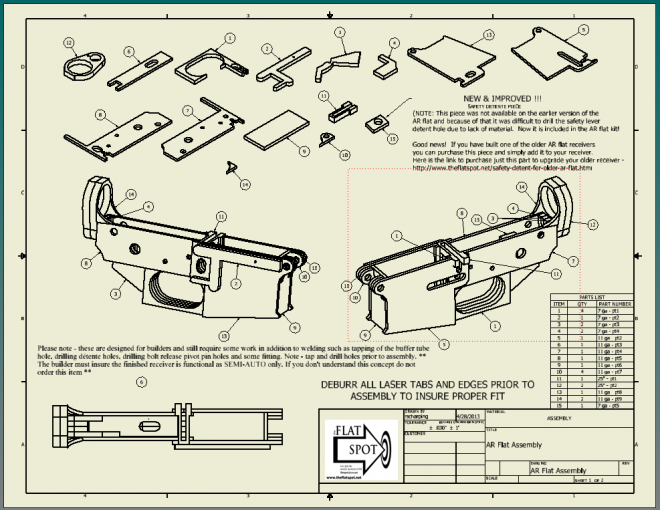

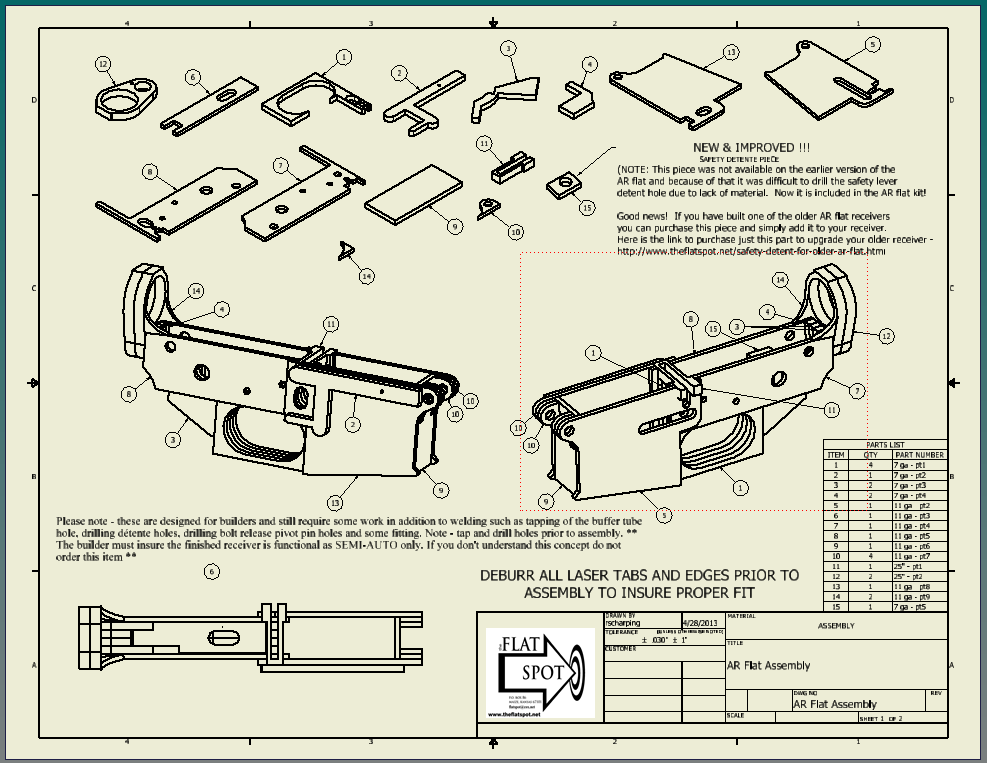

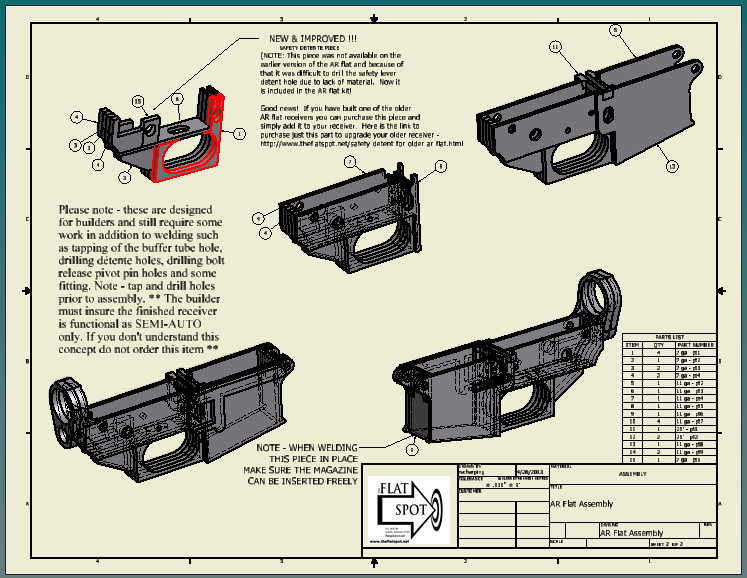

Now with NEW & IMPROVED SAFETY DETENTE PIECE (NOTE: This piece was not available on the earlier version of the AR flat and because of that it was difficult to drill the safety lever detent hole due to lack of material. Now it is included in the AR flat kit! Good news! If you have built one of the older AR flat receivers you can purchase this piece and simply add it to your receiver. Here is the link to purchase just the safety detente piece to upgrade your older receiver –

http://www.theflatspot.net/safety-detent-for-older-ar-flat.htmlPlease note – these are for builders and still require some work IN ADDITION TO WELDING such as tapping of the buffer tube hole (many builders choose to simply weld a castle nut on the rear of the buffer tower instead of tapping – We offer castle nuts here – http://www.theflatspot.net/ar-15–ar-10-castle-nut-for-buffer-tube.html), drilling détente holes, drilling bolt release pivot pin holes and some fitting. Note – tap and drill holes prior to assembly. Deburr the tab from all parts to insure proper fit during assembly. Please see the cad drawing files below for assembly instructions.

Your Privacy Choices

Your Privacy Choices