A professor and her team at NC State has developed a type of metal foam that is capable of stopping some of the most powerful small arms rounds in use by the military. Sandwiched between a ceramic strike face and a Kevlar or aluminum backplate, the ballistic composite is effective even at thicknesses of 8mm 25mm or less.

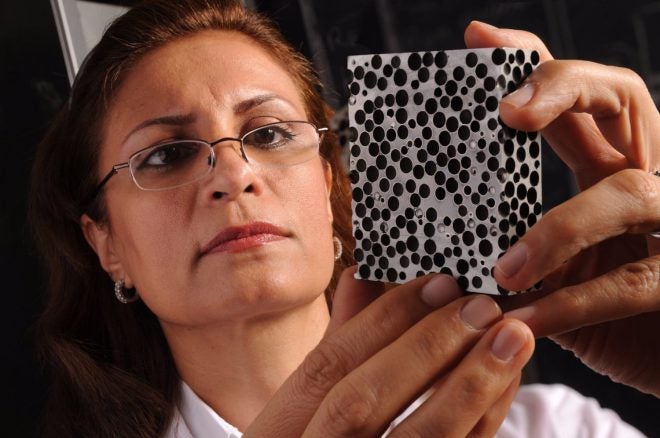

Professor Afsaneh Rabiei’s Composite Metal Foam (CMF) has passed the Department of Justice certification for Level IV body armor and is being tested for other applications such as radiation protection and extreme temperature exposure.

From Popular Science:

Developed by NC State professor of mechanical and aerospace engineering Afsaneh Rabiei, this foam absorbed so much of the bullet’s impact that the indentation on the target was less than a third of an inch (8mm, to be exact). The armor itself is just an inch thick, and it’s made of boron carbide ceramics as the strike face, a composite metal foam as an energy-absorbing middle later, and either a strong aluminum 7075 or Kevlar panels backing it up.

Rabiei tested the foam against the standard NATO 7.62×51mm rounds. She also tested it against the 7.62 × 63-millimeter bullet, a type of ammunition rarely used in combat today. The composite metal foam armor met the Department of Justice’s standards for Type IV armor, useful against armor-piercing bullets.

Metal Foam From NC State:

Composite metal foams (CMFs) are tough enough to turn an armor-piercing bullet into dust on impact. Given that these foams are also lighter than metal plating, the material has obvious implications for creating new types of body and vehicle armor – and that’s just the beginning of its potential uses.

Afsaneh Rabiei, a professor of mechanical and aerospace engineering at NC State, has spent years developing CMFs and investigating their unusual properties. The video seen here shows a composite armor made out of her composite metal foams. The bullet in the video is a 7.62 x 63 millimeter M2 armor piercing projectile, which was fired according to the standard testing procedures established by the National Institute of Justice (NIJ). And the results were dramatic. (The video can also be found at https://www.youtube.com/watch?v=lWmFu-_54fI).

“We could stop the bullet at a total thickness of less than an inch, while the indentation on the back was less than 8 millimeters,” Rabiei says. “To put that in context, the NIJ standard allows up to 44 millimeters indentation in the back of body armor.” The results of that study were published in 2015.

But there are many applications that require a material to be more than just incredibly light and strong. For example, applications from space exploration to shipping nuclear waste require a material to be not only light and strong, but also capable of withstanding extremely high temperatures and blocking radiation.

Last year, with support from the Department of Energy’s Office of Nuclear Energy, Rabiei showed that CMFs are very effective at shielding X-rays, gamma rays and neutron radiation. And earlier this year, Rabiei published work demonstrating that these metal foams handle fire and heat twice as well as the plain metals they are made of.

Now that these CMFs are becoming well understood, there could be a wide array of technologies that make use of this light, tough material. Armor, if you’ll forgive the pun, barely scratches the surface.

Your Privacy Choices

Your Privacy Choices