Here are pictures of a preliminary setup for creating rifling grooves in a piece of steel tubing by using a 3D printed spiral insert, lots of salt water and a battery charger. Electrochemical Machining is a process whereby metal is removed by passing an electrical current through a solution, the insert in this case exposing the specific areas to be ‘cut’ during the process. The results are quite interesting and certainly open up some possibilities for homebuilders.

“This is Jeffrod’s ECM jig, 5 inches long with a 0.813 diameter printed in black PLA and setup for 4 grooves using 26 gauge steel music wire for the electrode.”

“ECM jig hooked up to a Schumacher SE-82-6 12 volt manual battery charger (12v@6/2a; 6v@6a) at 6amps for 10-15 minutes. Note: this Rifling machine has no moving parts.”

The first test results showcasing the ease with which material can be removed in short order:

Salt, 12v battery charge, water supply (orange bucket) and rifling jig setup (green bucket).

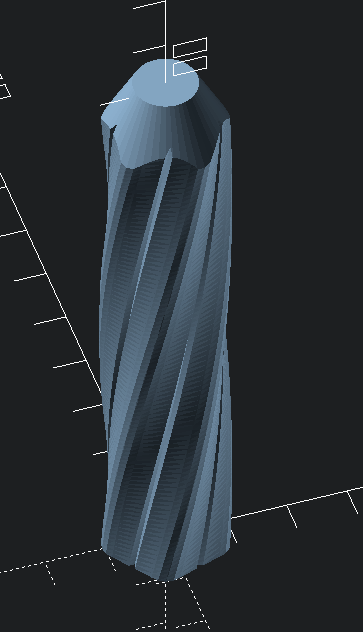

The results of a four inch twisted pentagonal cylinder with five grooves:

The complete process can be viewed here along with two rather long videos explaining everything above.

Your Privacy Choices

Your Privacy Choices