Thanks to my friend Tom for introducing me to Keith Biddle of Keith Products Co. He is a machinist that is only 5 miles from my house. Keith picked up machining from his father. Mostly self taught, Keith has been machining for most of his life.

At first glance it looks like your typical machine shop with components all over the place. But once Keith found out that I was into firearms, he started pulling out bits and pieces he made.

For a local gun store he made these A2 stock spacers. Now while there are stock spacers out there, I have not seen someone make them in different lengths.

Combined, I think they could make a rather interesting suppressor design.

Keith also showed me a clamp on rail system for adding optics to a fully supported barrel revolver like this Smith and Wesson.

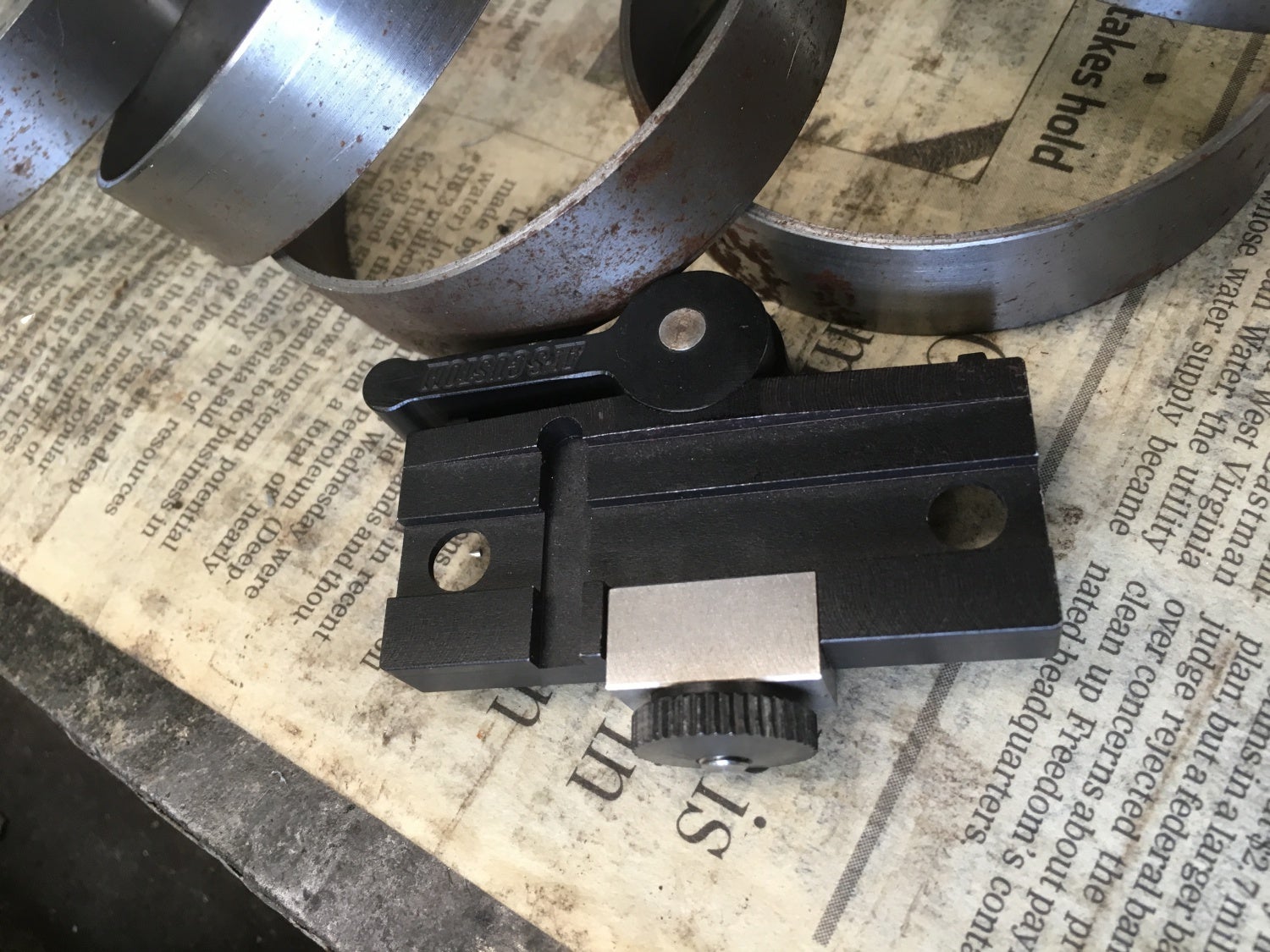

Below is Keith’s swing arm optic mount for an Aimpoint Pro that he made in 2004.

While it seems rather pedestrian now, this would have been amazing back in 2004. The knob adjusts the tension and there are springs under the clamp to push it open when the lever is unlocked.

Here is a collaborative item he made with his friend Rudy. It is an adjustable sight that can be attached to any shotgun rib.

Below is the pin that sets the height of the adjustable sight rib.

Once I saw what Keith could do, I ran home and grabbed my project revolver that I picked up during a Black Friday sale. It is a Heritage Rough Rider that was on sale for only $99 at Field and Stream. Last year I had someone help thread the barrel 1/2×28. The next idea I had was to machine the top strap to accept Aimpoint T1 style red dots. Keith was excited for the challenge. I had already measured the .22LR revolver and knew there was enough material but the method of attaching the optic was difficult. How do you counter sink the screws when you can not get an endmill under the top strap? After a little back and forth coming up with different methods, Keith came up with this simple solution. Come at the receiver at 90 degrees and mill out space for the screw heads.

More cool stuff to come from this machine shop. You won’t believe who his Uncle was.

Your Privacy Choices

Your Privacy Choices