In the early 1970s, Nelmo Suzano had already decided to concentrate his design efforts on submachine guns, at the same time that he tried to attract the necessary funds to support his design work and, eventually, create production facilities. Of all places, some support came from a most unlikely source, a shrimp boat shipyard in Rio de Janeiro’s seaside suburb of Caju whose owner, one Bruno Maconi, made funds available for the purchase of some used machines and tools. A company called SOCIMARTE – Sociedade de Máquinas Marte Ltda was then created, from which a new SMG design took shape in 1971.

The SOCIMARTE SM 9 was Nelmo’s first design to incorporate a magazine-in-grip configuration. Gun is seen here with the wooden stock detached.

The resulting blowback-operated 9x19mm MOD. SOCIMARTE SM 9 was a clear departure from the earlier, bulky “Sem Nome” (“Nameless”). It was a much more compact design featuring a pistol grip located somewhat in the center of the body, where a 32-round magazine was placed. Fitted with side wooden panels, the grip had a safety lever on the rear side that had to be kept pressed by the firing hand so as to avoid accidental discharges if the bolt moved as a result of the gun being dropped on the ground, for instance. Also made of wood was a forward handguard and the stock, which could be either folded to the left side of the gun or detached, altogether.

The SM 9 with the wooden stock in place. Grip safety lever on the rear side of pistol grip is discernible.

Alternatively to being fully removed, the stock could be folded sideways to the left of the gun.

All informal tests conducted at the time by the designer, invited friends, and, non-officially, by LE and military people showed that the weapon could be a feasible commercial proposition if given some improvements and, also, if available in production numbers, something that was clearly beyond the modest capabilities of SOCIMARTE. Thus, further search efforts by Nelmo eventually met, in 1972, a welcoming Bernardino Gonçalves Martins, the visionary owner of a Rio de Janeiro-based company called Bérgom S/A, manufacturer of air-conditioners, refrigerators, and steel furniture, whose already installed machines could come in handy for the purpose at view. In addition to that, the owner’s son, Luiz Gonçalves, was a firearms enthusiast and an expert in industrial processes as a whole, and soon became a close friend of Nelmo Suzano’s and a longtime participant is many projects.

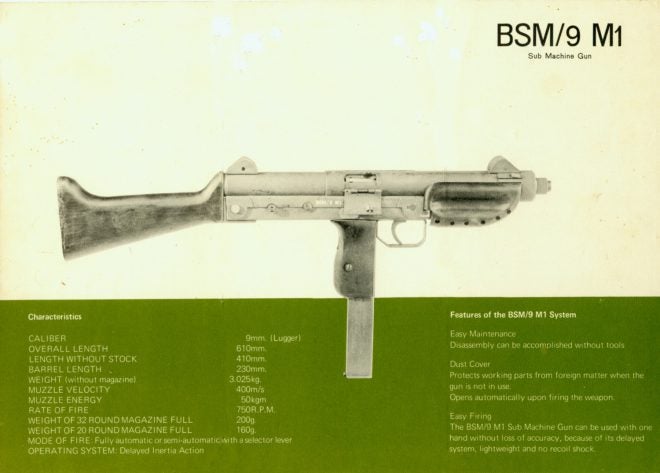

This rare Bérgom S/A English-language sales leaflet of the early 1970’s shows that the newly-established company was trying to reach the international market. Although marked BSM/9 M1, the gun shown appears to be the earlier SM 9, from which the grip safety lever was removed (a much closer look at the picture appears to show this).

The business end of the BSM9/M1. Ventilation orifices in the handguard and the blade-type cocking piece( at about 45 degrees to the left side) are shown.

Already under the Bérgom name and the designation BSM9/M1 (Bérgom Sub-Metralhadora 9mm Modelo 1), that first prototype was finally submitted to a testing program at Brazilian Army’s Campo de Provas da Marambaia (Marambaia Proving Grounds) in Rio de Janeiro. This was an official requirement so that the product was technically okayed and approved for series production and commercialization. And approved it finally was in June, 1973 (ReTEx Number 728 certification document).

This Bérgom BSM9/M1 kept in storage by Brazilian Army’s Marambaia Proving Grounds is the example used in the certifications tests carried out in 1973. A smoother, better overall finish is evident in the gun metal and wooden parts. Note unventilated handguard.

The BSM9/M1 had a pretty unusual delayed blowback action, which Nelmo called “friction limit force” or “delayed inertia action”: when the bolt hit the breech, two small wedges in it were inertially projected sideways onto the flat (no recesses fitted) walls of the tubular receiver. In addition to the close fit of bolt/walls, producing a kind of pneumatic effect, this was enough to delay the bolt’s rearward motion, also allowing the bolt itself to be lighter and contribute to the weapon’s stability/controllability in automatic fire (cyclic ROF was about 750 rounds per minute). A spring-loaded dust cover on the ejection port opened automatically when the gun was cocked or fired. The hand-pressed safety bolt-blocking lever was replaced with a clever internal inertia-activated system which worked pretty much in the fashion of the early car seat-belt mechanisms.

Right side view of the BSM9/M1, spring-loaded ejection window cover open, with the wooden stock folded to the left. Magazine capacity is 32 rounds.

This conical complement on the gun’s barrel mounting nut was added while the gun was in Army’s hands for testing, but its actual purpose is unknown. It seems too small to act as a flash hider, and incorporates a small catch on the lower part. Any guess?

Other features of the gun: Overall length, 610mm; length without stock, 410mm; barrel length, 230 mm; muzzle velocity, 400 m/s; weight (32-round magazine, full), 3.2kg.

Pretty soon, still in 1973, somehow news of Nelmo’s recently Army-certificated submachine gun reached… Algeria! The local military wanted to take a closer look at the BSM9/M1 and see how it performed in the typical sand-and-dust environment of that region. Creator and creature flew to Northern Africa, and for some days gave the gun hell! The field evaluation tests were reportedly highly successful, to the point that the Algerians decided to establish a factory there and immediately wanted four guns in a slightly updated, pre-series configuration delivered for additional, more comprehensive field tests. A small prototypes/R&D lab was created by the Bérgom company in a Rio de Janeiro suburb, a small workforce being able to complete the four requested guns by mid-1974.

Ready to go, but not really… Four BSM9/M1s were ready in 1974 to be sent to Algeria as part of that nation’s intended program to locally manufacture the guns. However, internal problems with an unreliable Bérgom partner ended the venture.

The new guns were essentially the same design, but incorporated changes that would probably be used in series-manufactured examples. In addition to a better general finish, plastic (early polymers) components found their way to the detachable stock, handguard, and side panels of the pistol grip. The sights protection structures became hoods instead of the earlier side ears, while the barrel was attached to the receiver front end with a metal glove that doubled as a muzzle brake.

The Bérgom BSM9/M1 employed plastic components (removable stock, pistol grip panels, handguard), its wide sight radius being evident in photo.

A BSM9/M1 with the magazine removed and the stock detached. Note slightly different (hooded) sight protection structures.

Regrettably, the BSM9/M1 program did not progress further than the small pre-series batch. It just so happened that one of partners of the Bérgom company, for some unbelievable reason, did not pass all the official Algerian Government correspondence regarding the production plans to either Nelmo or his friend Luiz, which soon made the North African guys think that the Brazilians were no longer interested in the venture, closing all communication channels.

A BSM9/M1 field stripped. The two wedges that projected sideways from the cylindrical bolt to delay the blowback action are shown by the arrows.

The barrel mounting nut featured an extension glove that doubled as a muzzle brake. Also clear in photo are the hooded front sight protection and the blade-type cocking piece just beside it.

With the stock removed, the BSM9/M1 was adequately balanced to make single-handed firing a reasonably viable proposition in an emergency other than showing off at the stand for a new girlfriend. Or for a mere pictures-taking session, as in the author’s case here.

Yeah, that hand-finds-hand principle (found in Uzis, MACs and other SMGs) has always been welcome when it comes to quickly changing a magazine.

Your Privacy Choices

Your Privacy Choices