Having left the Bérgom company in 1975, a still hopeful Nelmo Suzano kept his mind pretty active in the creations department. His new plans involved the conception of a family of more modern-looking weapons which included a 9x19mm submachine gun, a 5.56x45mm assault rifle, a .22LR semi-automatic carbine for commercial use, and a .22LR selective-fire carbine for police/prison guard duties. In about three years, i.e. in 1978, enough technical drawings and theoretical studies had been accumulated so as to allow him to go ahead in prototypes construction.

Since all the new models would employ polymers (often called “reinforced plastics” at that time), all the early prototype work was carried out in the facilities of a São Paulo-based company, Goyana, which specialized in manufacturing plastic furniture and things like that. At the same time, the designer and two more partners founded LAPA – Laboratório de Projetos de Armamento Automático Ltda, a Rio de Janeiro-based company specialized in weapons design.

The SM MOD.3 prototype was completed by Nelmo Suzano in approximately one year, most of the work being carried by the designer in the facilities of a plastic furniture factory in São Paulo.

In about 12 months, the SM MOD. 3 (SubMetralhadora Modelo 3) prototype was born and informally — but intensely — tested by Nelmo and friends, being considered capable of undergoing the tough Brazilian Army product certification tests at the Campo de Provas da Marambaia (Marambaia Proving Grounds), in Rio de Janeiro. After having flawlessly fired a total of 6,500 rounds of 9x19mm ammo under the most adverse (sand, mud, rain, heat and cold environment) conditions included in the official program, the gun passed it with flying colors and got the coveted ReTEx – Relatório Técnico Experimental No. 995 on November 23, 1982.

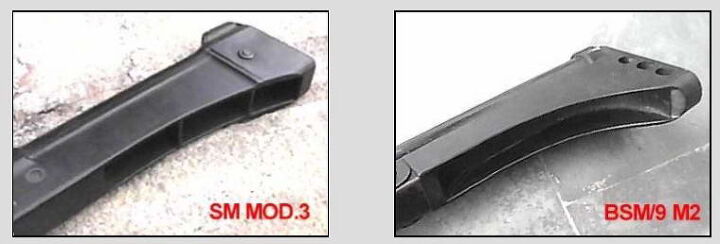

Although externally different from the earlier Bérgom BSM/9 M2 “Skeleton”, the LAPA SM MOD.3 did incorporate common features such as the straight-line (barrel/butt plate) configuration, the raised sights, and the use of polymer components.

Comparison of the two polymer stocks.

Nelmo’s “plastic age” prototype was, mechanically, a pretty conventional blowback-operated gun firing from the open-bolt position. The tubular receiver projected well into the stock hollow, thus giving the bolt a comparatively long (150mm) rearward travel when firing, thus aiding stability. The sights (rear flip-type aperture, 50-100m; front post; radius, 290mm) were mounted on top of massive metal structures welded to the receiver. This and the gun’s firing mechanism were housed in a two-part body made of injected plastic material, the lower module comprising the handguard, magazine housing, pistol grip, trigger guard, and stock. The upper portion covered the receiver and included the rear sight protection structure, an AR-10-type carry handle. The cocking piece was a curved affair that ran rearwards about 85mm within the handle to get the gun ready for action, remaining stationary during firing.

This close-up view shows details of the gun’s work area, with the fire selector set for “S” (rear), the cocking piece within the AR-10-inspired carry handle (actually, the rear sight covering structure), and the blade-type magazine catch.

The ejection port was on the right side, having a spring-loaded cover that snapped open when the weapon was cocked or when the bolt moved forward. The magazine was inserted upwards in a housing just ahead of the trigger guard, being a 30-round, staggered-row, single-position feed, straight-line metal-box type in the prototype, but production models were expected to use 32-round curved plastic magazines. The magazine catch was placed aft of the housing, being pressed forward to release the magazine from the gun.

Two views of the LAPA submachine gun with the 32-round curved magazine of polymer construction that was to be used in production weapons.

The fire-selector lever on the left side just above the pistol grip had three settings, “S” (Safety), to the rear; “30” (automatic), upward; and “1” (semi-auto), forward. The safety position blocked the trigger and firing mechanism, and the gun possessed an additional safety in the form of an internal inertia-type locking device that automatically blocked the bolt at its forward position in case the weapon was accidentally dropped or hit on the butt, preventing unintentional and hazardous firing. The bolt remained closed after the last round was fired.

Initial and final stages of the SM MOD.3 subgun field-stripping process. Note the ventilation holes in the receiver’s forward portion.

If you are interested in such things, here’s how the SM MOD.3 was field stripped. The three metal pins (production guns would have only one) that secured the body together were first removed sideways to the right with the aid of a round of ammunition or any other pointed object. This allowed the buttplate to be pulled backwards and detached from the stock. The body could then be separated into two halves, the bottom one exposing all the firing mechanism for cleaning, making further disassembly unnecessary. The tubular metal receiver, with the integral sights, was pulled away from the top plastic cover/handle allowing, at the same time, the cocking handle and its rod to be detached from the bolt. Unscrewing of the receiver’s rear cap then allowed the return spring and bolt to come out. The barrel was removed from the forward end by unscrewing its mounting nut. Be sure: it takes much longer to describe the procedure than actually doing that.

Basic specifications: barrel (4 grooves, RH twist, muzzle velocity 405 m/s) length, 202mm; overall gun length, 623mm; gun weight, no magazine, 2.8kg; weight with loaded 30-round magazine, 3.4kg.

Regrettably, the SM MOD.3 did not find the expected acceptance from the market, mainly due to the LAPA concern’s lack of promotional experience. Also, I vaguely remember hearing from a top-ranking Brazilian Army officer at the time: “Bah, it’s too modern for us!” I’d dare to theorize on how it would succeed marketwise today, almost 40 years after its inception. Given a bunch of Picattiny rails here and there, of course…

These two views show that the rear sight was protected by the carry handle structure and that the massive front sight structure configuration was much based on the designer’s “Skeleton”, the earlier conceptual studies prototype.

One more view of the SM MOD.3 with the 32-round curved, waffle-style plastic magazine proposed for production guns.

Rear sight protection structure or carry handle? Oh, well…

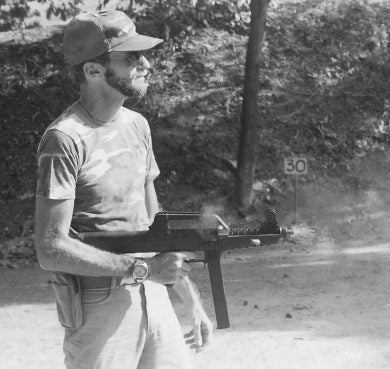

Light, compact, pleasant to handle and shoot. This summarizes the author’s opinion about the LAPA SM MOD.3.

Look, mom! One hand! That polymer wonder was controllable enough to allow skinnier shooters to fire it single-handed at full auto. The prototype’s cyclic rate of fire was under 500 rounds per minute or so, which reminded one of the U.S. M3/M3A1 Grease Gun of WWII.

Hit the dirt… and keep firing!

Your Privacy Choices

Your Privacy Choices