Late in 1978, Nelmo Suzano started work in the development of a 5.56x45mm assault rifle in the bullpup configuration, a long-time idea that had flashed on-and-off in his mind. Sure, the British EM1 and EM2 of the 1950s may have sparked the fire, more so in the mid-1970s when the so-called E.W.S. (Enfield Weapon System), consisting of an Individual Weapon (XL84) and a Light Support Weapon (XL85), both in the proposed 4.85x49mm caliber, appeared in the scene. However, Her Majesty’s troops would only start receiving the resultant 5.56x45mm SA80 (Small Arms for the 80s), or L85A1, in 1985. For the record, the Austrian Army started using its Steyr StG77 (the AUG) in 1977, at just about the same time that the French Army was taking delivery of its first FAMAS F1s.

As mentioned in this series’ Part 4, the designer formed a partnership with two other persons to form LAPA – Laboratório de Pesquisa de Armamento Automático Ltda, in Rio de Janeiro. However, he spent about one year in São Paulo in order to produce a relatively crude conceptual prototype at the facilities of a plastics products (furniture, mainly) manufacturer. Having shown that the whole design incorporating his ideas – some of them, novel – was a viable proposition, work began on a second, final prototype, which was ready in 1982. Designated Fuzil Automático Modelo 3 (or F.A. MOD. 3), Nelmo’s bullpup rifle immediately caught my attention when I first saw and handled it in a Rio de Janeiro downtown office in October of that year. And much more so along the next 18 months when I watched and was invited to participate in many of the gun’s fire tests that would lead to have it sent over to be submitted to official Brazilian Army product certification tests.

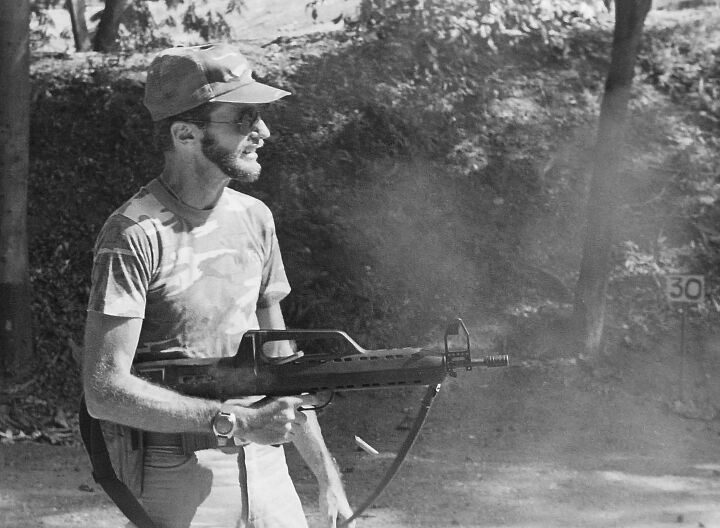

The F.A. MOD.3 definitely had (in the author’s opinion, at least) elegant lines, notwithstanding its massive elevated front sight structure. Weapon is seen here with a 30-round polymer magazine, STANAG-compatible, proposed for production weapons.

The rifle’s smooth, somewhat futuristic lines were the result of its body being made of “high-impact injected plastic material”, as polymers were generally called then, which formed a two-part (upper, lower) shell which housed the mechanical stuff, the two halves being held together mainly by the butt plate and a single take-down pin just aft the pistol grip. Its operation system was a pretty conventional gas-and-piston action, breech locking being the responsibility of a rotating bolt with seven locking lugs. But it was in the firing mechanism department that the F.A. MOD.3 broke new ground, mainly for a shoulder weapon. The whole thing was summarized by the markings found around the fire/action selector lever, located on the left side of the stock between the magazine housing and the butt plate. There were three firing positions (“1”, “3”, “30”) and two action settings (“DA” and “SA”), which are self-explanatory. Significantly, there was no “S” (Safety) setting.

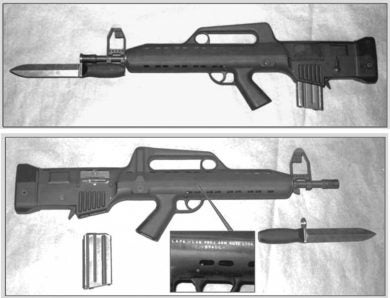

Magazine change (here, a 20-round AR-15/M16 type) was a straightforward, one-hand operation thanks to the location of the catch at the rear of mag housing.

Before or after cocking and feeding the rifle, which was done by pulling back and releasing the cocking lever which ran inside an AR-10-style carry-handle, the operator set the fire selector to any of the three fire positions. If fired immediately, the gun’s hammer would be naturally set for single-action operation, featuring a lighter and shorter trigger pull. After firing some rounds, or if no immediate use was anticipated, the firer might turn the lever to the “DA” (Double Action) mark and return it to any desired fire position. This dropped the hammer securely and allowed the gun to be carried safely, but still ready for immediate action. All that was needed was to pull the trigger, though requiring a longer and heavier pull. If more precision was eventually required in single or first shots, you just moved the lever to the “SA” (Single Action) marking and returned it to the desired fire position, giving the trigger a shorter and lighter pull. Simple instruction and training procedures easily turned this somewhat complicated explanation into practical operation.

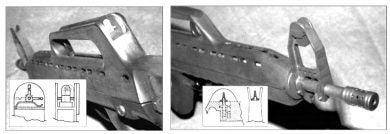

One lever fit all: a single switch was used to choose firing (“1”, “3”, “30”) and action (“SA”, “DA”) settings. A clever solution to carry a rifle, say, in a patrol, ready to use without having to disconnect any safety device.

All in all, the Nelmo’s baby was pretty comfortable to shoot after one got used to the then not-too-common bullpup configuration and the resulting ergonomic characteristics, such as the lighter front and the way to insert magazines into the rear-located housing. Oh, yes, the gun was already interfaced to use standard AR-15/M16-type (okay, STANAG) magazines, but plans existed to make 20-, 30- and 40-round plastic magazines available for production models. One thing that was immediately evident when shooting was the gun’s, say, inherent stability resulting from its straight-line (barrel axis-buttplate) configuration. This could easily be shown with a simple trick: have it stand unsupported on the butt plate! The stability I’ve mentioned was even more evident when full-auto fire was used, even when showing off to bystanders by going rock-and-roll single-handed…

With a cyclic rate of fire of 650-700 rounds per minute, plus its straight-line configuration, Nelmo’s bullpup rifle was pretty stable to fire in rock-and-roll, even single-handed. Watch out, Rambo!

The rifle’s favorite trick to show off its straight-line design was to stand on the buttplate… unsupported.

After having fired over 8,000 rounds without any major problems, the gun was considered ready to be sent over to undergo official Brazilian Army tests at the Campo de Provas da Marambaia (Marambaia Proving Grounds), in Rio de Janeiro, where it arrived sometime in 1984 together with a batch of 6,000 5.56x45mm M193 rounds of ammo acquired by the LAPA concern fresh from the stocks of CBC – Companhia Brasileira de Cartuchos, the sole Brazilan manufacturer. A short time later, however, Nelmo was informed that his bullpup rifle was presenting “some extraction problems” after firing about 500 rounds during the test program, and went to the Army facility to take a look. He then noticed that several ejected cartridges had clear overpressure bulges in the brass. Following detailed measurements of the weapon’s mechanical parts (emphasis on the breech and bolt areas) for eventual headspace problems and nothing wrong having been found, the designer then turned to the ammunition. Each and every round of the 5,500 or so remaining cartridges was carefully examined and measured, which resulted in finding out that over 60% of them had considerable discrepancies in the shape/dimensions of the body-to-shoulder area. This alone may have resulted in the problems encountered during the tests, but it was also found that many cartridges displayed substantial case/projectile alignment faults, not to mention that some other rounds were found with the primers… inverted! A furious Nelmo Suzano immediately travelled to São Paulo, where the CBC factory was located, and spread the faulty ammo on the desk of a top executive. Surprised and cordial, he said that serious internal investigations would follow and that “heads would roll”… This major hindrance resulted in the FA MOD.3 being taken out of the Army tests, to which it was never returned.

Closer views of the rifle’s sights: the rear unit was a two-position (100-400 meters) flip aperture, adjustable for windage and well protected by the carry handle structure; the front sight was a protected post adjustable for elevation.

In the meantime, however, the gun’s appearance in major international publications, specially the prominent British annual catalog “Jane’s Infantry Weapons”, called the general attention. Among the correspondence received by the LAPA company were letters, telegram and telex messages (no Internet at that time, folks) from the Malaysian Government during a two-year (!) period that were aiming at the possible establishment of a local factory to produce the Brazilian bullpup rifle under license. That country’s military wanted that eight guns were “immediately” sent over for field tests, but as only that single prototype existed and there were no funds to build the required batch, the plans went down the drain. This fact, plus serious internal divergences within the Laboratório de Pesquisa de Armamento Automático Ltda management, marked the end of the Fuzil Automático Modelo 3.

Basic technical data of the LAPA F.A. MOD.3: barrel length, 489mm (6 grooves, RH); length overall, 738mm; weight with loaded 20/30-round metal box magazine, 3.5/3.6kg; cyclic rate of fire, 650-700 rounds per minute. For the record, the designer had planned to have production rifles with an empty weight of under 2.8kg.

Two views of the sole prototype built. The 20-round magazine came straight from an M16 and the “generic” bayonet was made by Nelmo Suzano simply to show how it fit the gun. The markings on the right side read: “L.A.P.A. – LAB. PROJ. ARM. AUTO. LTDA./BRASIL”.

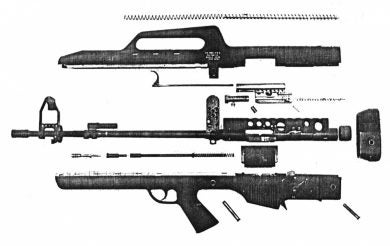

This is the only surviving picture of the F.A. MOD.3 field-stripped. In spite of the low quality, it’s enough to give a general idea of what the rifle was like inside.

One more view of the nifty LAPA rifle. During several informal demonstrations to military and LE people, the sentence “We want this rifle!” was often heard by the author. Unfortunately, one more gun that never was…

Your Privacy Choices

Your Privacy Choices