Would you like to know what the future of silencer design looks like? Take a long look at the Brevis II Ultra, a six ounce 5.56mm centerfire rifle suppressor. It represents what we may later regard as one of the biggest breakthroughs firearms development in recent history.

Sounds pretty dramatic, doesn’t it? What if I told you that the designers of that same silencer are striving to make a similar model that will weigh close to a standard flash hider and can handle a barrel length of seven and a half inches? That’s what I thought.

But I’m getting ahead of myself. Let’s backup a bit and talk about the Brevis II Ultra.

INTRODUCTION:

Delta P Design @TFB

First off, a small disclosure – I bought the Brevis II. As you may know, manufacturers provide TFB with guns and products to review on a test and evaluation basis. After the review period, firearms are returned to the factory. Not this review; the Brevis marks the first purchase I have made from a TFB evaluation, which might give you a small clue as to the direction of this write-up.

Delta P Design @TFB

The Delta P team is a fairly secretive bunch. Obviously with a product as progressive as the Brevis, I had a lot of questions, and many of them still remain unanswered. So why all the secrecy?

For one, this company is living on the very edge of silencer manufacturing technology and have invested a huge amount into design, research and testing to get to a commercially viable product. I also got the idea that Delta P may be providing products to ‘specialized teams’ (my own conclusion). So I didn’t push back – too much – when I got “I’m not ready to comment on that yet” responses from Vice President David Strong.

Delta P Design @TFB

So, although I really wanted to see pictures of a Brevis being made, the internal baffle structure and other technical details, I realize that for the protection of Delta P’s intellectual property, some things are going to remain a mystery. Of course, Strong reminded me that anyone can buy a Brevis and cut it open. (Please don’t – that’s just sad.)

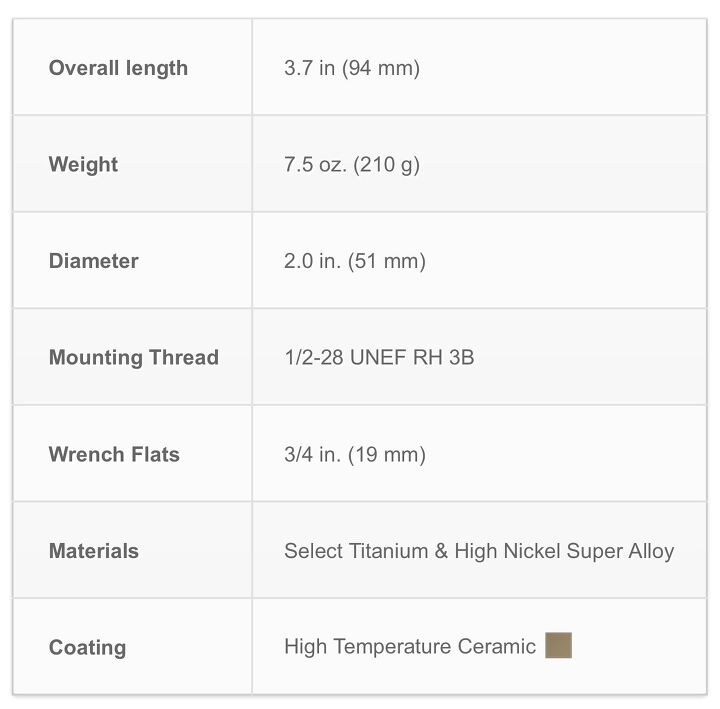

SPECIFICATIONS:

Delta P Design @TFB

The Delta P Design Brevis II Ultra is not machined, turned, or otherwise constructed by traditional methods. This silencer is made of 100% Titanium by a process called Additive Manufacturing (you may know it better as 3-D printing). There are no separate pieces, no baffles, no end caps and no welds . The Brevis is a single piece of un-worked material which leads in part to a dramatic weight savings and increased strength.

The team who invented the Brevis had very specific goals in mind, and strangely enough, suppression wasn’t one of them. Sure, it suppresses just fine, but more importantly it is short, light and reduces flash right up there with the best flash hiders currently available. Delta P wanted to make the Brevis Ultra virtually disappears on the end of a users barrel. And it does.

How light is the Brevis? Using 5.56 cartridges as a tangible comparison, we balanced out the silencer with somewhere between nine and ten rounds. Shockingly light.

With most rifle silencers, all you really hope for is that it’s not too long and not too heavy. Not with the Brevis. My guess is that I could blindfold you, hand you an MK18 and have you guess by weight and feel whether or not that rifle had an OEM flash hider or a Brevis Ultra – and you couldn’t tell the difference.

MSRP:

- Brevis (Inconnel) – $1,386.00

- Ultra (Titanium) – $1,491.00

SETUP AND INSTALLATION:

Delta P Design @TFB

This part is easy – as long as your barrel is threaded properly to the correct pitch, just spin on the Brevis and lightly torque it down to specifications.

Quick detach fans might be disappointed at first, but the Brevis is designed to be installed and forgotten. And remember, there are no moving parts loosen or fail.

Delta P Design @TFB

SHOOTING AND COMPARISONS:

Delta P Design @TFB

I had planned on having some “special friends” bring a proper sound meter by for a proper decibel test but our schedules didn’t match up. So my friend and local dealer, Mark Cook from MAC Tactical was nice enough to stop in with plenty of rifles and silencers for a head to head comparison.

As with any centerfire rifle suppressor, the Brevis is not “hearing safe”. As such, you will never hear me suggest shooting suppressed rifles without some sort of hearing protection. However, for the comparison tests, I did remove my foam plugs for some of the shooting to get a raw feel for the blast reduction.

Here’s the subjective results: the Brevis was quieter than the AAC Mini 4 but louder than the Sig Sauer 7.62QD. How’s that for hard science?

Delta P Design @TFB

While the Brevis Ultra II wasn’t the quietest silencer I’ve had heard, it wasn’t the loudest either. I would describe the experience without hearing protection as being just on the edge of painful. But for a supersonic 5.56 round on a 10.3″ barrel, the reduction was more than acceptable.

The one observation I had that was the most interesting was that the sound reduction didn’t change much when using the Brevis on a longer barrel. Typically, longer barrels give the propellants more time to burn, reducing the blast further than their SBR kin. I wasn’t able to detect a significant change in suppression going from a 10.3″ barrel and a 17.3″ barrel.

Note: The SiCo flash hider weighs almost as much as the entire Brevis silencer.

Also, my MicroMOA adjustable gas block is tuned for the SilencerCo Saker 762 that is normally attached to this rifle. After the first shot with the Brevis, I noticed that I had to increase the gas flow for proper cycling. This is an indication that the Brevis does not force as much gas back down into the system and towards the shooter (sometimes referred to as back pressure).

Note: The SiCo flash hider weighs almost as much as the entire Brevis silencer.

Delta P Design @TFB

All things considered, the Brevis II is very close to what I would consider to be my idea of a “perfect” short barreled rifle suppressor. To understand my rationale, you have to remember that a centerfire rifle can never be made “Hollywood Quiet” with a silencer. So if ultimate suppression is not the goal, the focus should be on limiting the weight and any added length to the barrel. Add in “Best In Class” flash suppression and the Brevis makes for an impressive piece of kit.

Brevis II ULtra CONCLUSIONS:

As I like to explain in all my reviews, managing your requirements and expectations is the key to making solid equipment purchases. And I think that this is especially true when someone is considering a Delta P suppressor. If you want the quietest rifle suppressor, a quick detach system or have a limited budget, I’d hold off on a Brevis for now. On the other hand, if you are looking for a silencer that suppresses relatively well, has excellent flash reduction all with a minimal length and weight footprint – your can has arrived.

Downsides:

- Not super quiet

- Expensive

Neutral:

- Direct thread only

Positives:

- Lightweight

- Short length

- One piece construction (no parts to fail)

Fast forward five years and I picture every shooter owning at least one silencer, firearm or gun part that is constructed using additive manufacturing. Delta P Design has a big head start in the suppressor industry and as they refine their techniques and lower costs their market share will accelerate. I have no doubt that they have some products in development that are going to blow minds.

Delta P Design @TFB

Your Privacy Choices

Your Privacy Choices