This is a Guest Post by my friend Dickson Ly. Earlier I posted a photo of him and the rare Steyr ACR. Well Dickson was there taking a tour of the Steyr Arms Factory in Austria.

Austria is a country where many people have the stereotype image of people dressed up in lederhosen, drinking beer, listening to Beethoven music or the image of The Governator a.k.a. The Terminator a.k.a. Arnold Schwarzenegger. This is my third time traveling to Austria in 3 years, I have come to learn quite a lot about Austria but mainly Vienna. Through my work I was invited to visit Steyr Mannlicher, a firearm manufacturer that is over 150 years old, for a factory tour. I am a huge fan of Steyr – about 10 years ago I fell in love with the idea of Col. Jeff Cooper’s Scout rifle concept and Steyr produced the Scout with input from Col. Cooper. Last year I had acquired the SSG 08 precision rifle in .308Win. The rifle was designed with direct feedback from the Austrian EKO Cobra special unit (Think German GSG9 or the British SAS). It is an update to the legendary SSG 69 precision rifle released in 1969 originally designed for the Austrian army but also used by various countries around the world. And just last month I picked up the HS 50 M1 which is a magazine fed, bolt action, anti-materiel precision rifle in .50BMG.

When we are talking about a company that has a history of over 150 years with many technological innovations, your purchase goes towards supporting a company with a very long history and legacy of manufacturing firearms for various armies, police units and special forces around the world. To this day they still maintain a high level of quality and reliability unsurpassed by any other firearm manufacturer except perhaps high-end British or Italian shotguns.

For most people who purchase Ferraris, they buy it mainly for the extraordinary sound of its Formula 1 derived engines. In the case of Steyr, you are getting their highly accurate cold hammer forged barrel with their signature spiraling from the hammer forged machine. Not to mention, when we are talking about a company that has a history of over 150 years, your purchase goes towards supporting a company with a very long history and legacy of manufacturing firearms for various armies, police units and special forces around the world. On my SSG 08, I was able to achieve “one hole” accuracy at 100 yards using Federal 168gr Gold Metal Match ammo.

After a 4 hour drive from Budapest, Hungary, I arrive in the small town of Kleinraming which is 40 minutes away from the town of Steyr in the west of this small country. Once going through a well secured facility with locked gates, I was greeted by Oliver Bauer, their international sales manager.

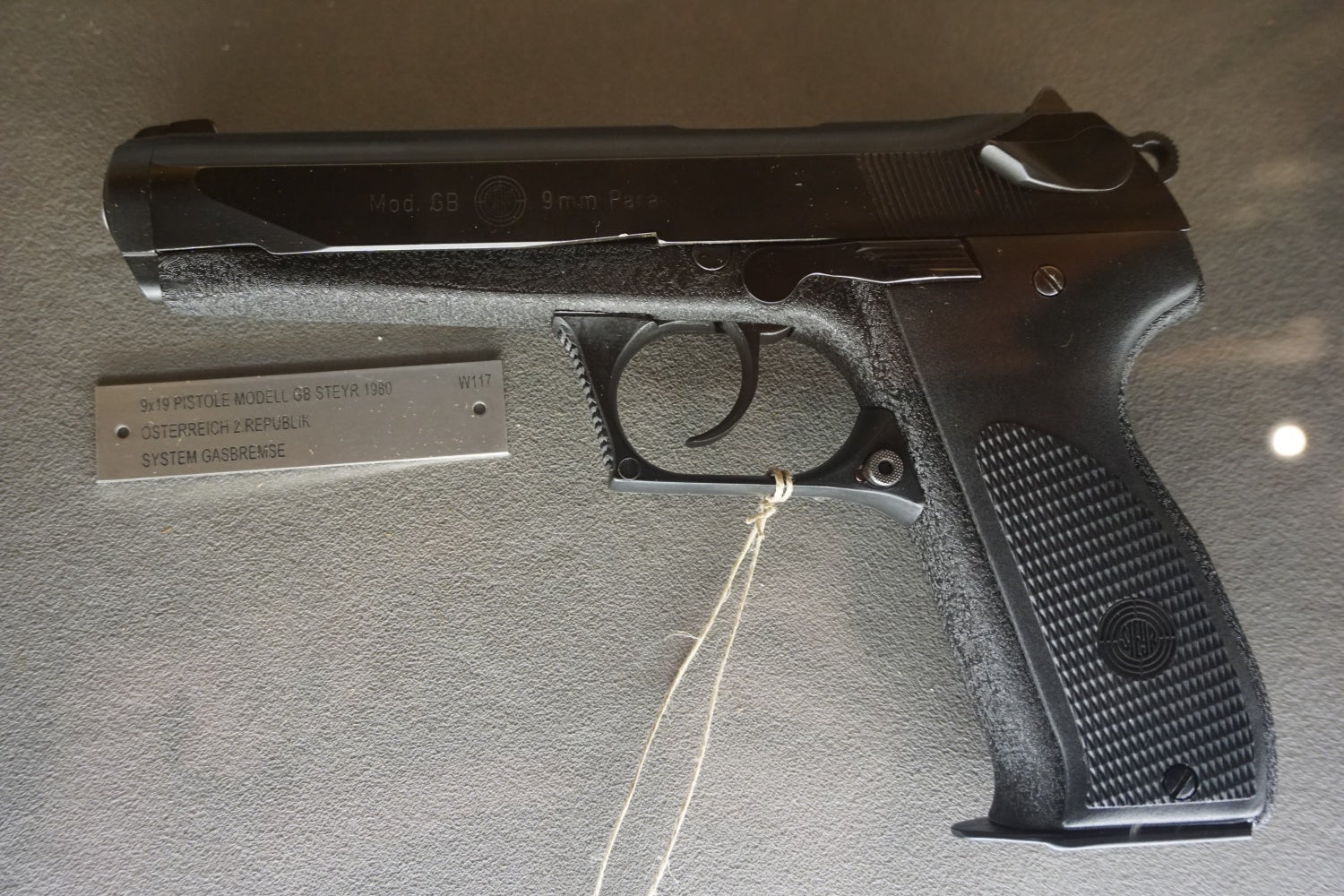

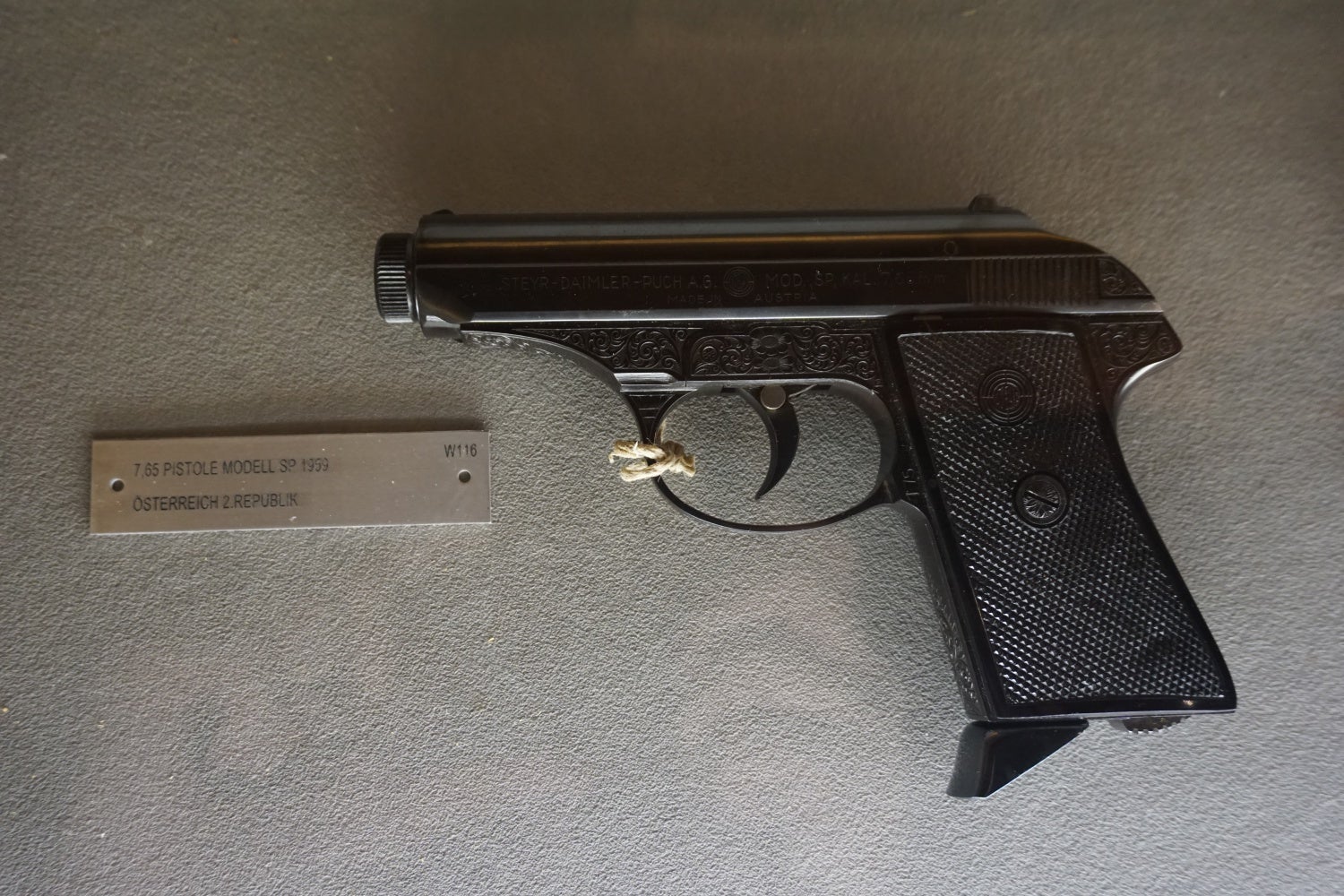

The first place Oliver took me to within the building is the “Waffensaal” or Historic Weapons Hall. It’s informally called the Wood Room. It was first built in 1915 inside the original factory at town of Steyr in Nordic Revival Style, but due to the move to the current location at Kleinraming each piece had to be carefully removed. All the pieces were made by hand.

In the Waffensaal is a complete collection of Steyr Mannlicher firearms dating back from 1800s. They are all resting beautifully within the gun cabinets. Each of these rifles were truly unique but due to time constrain I won’t be spending time discussing each one so I will let the photos speak for themselves.

I was then introduced to Martin, one of the staff at Steyr Mannlicher who is involved in product planning and development and prior to working at Steyr he served in the Austrian army.

I asked what Steyr rifle does he have and he was quick to mention that he hunts with a Steyr Scout. I smiled and told him I have one as well in its original Jeff Cooper setup (with a forward mounted, long eye relief Leupold 2.4x scope) but with the optional 10 round magazine adapters. I was also curious as to why Austrians seem to love hunting with rifles with wooden stock. Martin responded by saying it’s a proud Austrian tradition to hunt with a traditional wooden stock rifle. However, he was quick to say that polymer stock is much more practical option as they are more durable and weather resistant. I agreed whole heartedly. I’m also a bit worried to use a rifle with such nice wooden stock. I will cry if I ever drop it or scratch it against tree branches in the field.

Martin showed me their latest premium hunting rifle, the SM12 with a unique hand cocking system (H.C.S.). With this system you can easily decock and make the rifle safe with a pull with your thumb. It can then be quickly cocked and ready to shoot by pressing the thumb switch. All of this without moving the bolt back or touching the bolt handle. Seeing that it has a wood stock, he was quick to point out it also comes in a hunter green polymer stock featuring monolithic aluminum bedding (M.A.B.) called the SM12 SX. He also demonstrated the special fine tuned trigger with set trigger. It lightens up trigger pull significantly by pushing the trigger forward to set it and pulling it to fire. It’s a rifle with lots of special features indeed!

Resting on the corner of the room were 2 rifles I had requested in advance to look at. First one was the ACR (Advanced Combat Rifle) prototype that were designed for a US military contract to replace the M4. This particular gun appears to be the 2nd prototype with the receiver engraved “ACR 2 PROTOTYP” and directly below “MARZ 1989”.

If you look at the rifle at distance it resembles an AUG but beside the bullpup design and the use of polymer that is where the similarity ends.

It shoots flechettes contained in a special polymer cased ammunition in a polymer magazine that holds 28 rounds.

The round ejects to the bottom ahead of the magazine so it can be fired both left and right handed with ease.

The barrel is housed inside the smooth polymer body only exposed by the bird cage flash hider. Upon careful inspection I noticed at 1 o’clock it has 3 rows of drilled holes on the muzzle device so that makes it a flash hider and a compensator combination!

The charging handle is AR15 style and its operations is basically the same. Unfortunately, Martin did not have much information about these rifles or how they operate, as I did not find any bolt hold open on the ACR or how it disassembles, presumably it was held together by pins. I was fairly excited to see these rifles in person, in fact Martin wasn’t sure where these rifles were stored in the facility.

The second rifle (if we can call it a rifle because it may be more appropriate to call it a canon), is called the IWS 2000 (Infantry Weapon System 2000) and it was designed to fire a special 15.2mm armour piercing fin-stablized discarding sabot round.

Once again there’s very little information available for this rifle and it appears the bolt is missing on this particular sample. I do know that the barrel rifling is smooth bore. Due to its weight and large size, it can only be fired prone as it’s designed for anti-materiel use. It also makes heavy use of polymer and majority of the weight is in the long thick barrel. Unfortunately, the optic was also missing and it was not equipped with iron sights. The only thing I was able to adjust on it is the rear monopod as it has a big knob at the rear. It appears both rifles have not seen the light of day for a very long period as most of the photos on the internet dates back to the 1990s. So what you’re seeing in this article is truly special!

The actual tour hasn’t even started and we’ve already covered a slew of information!

This is where I bring you the readers the bad news. I was informed no photographs are allowed in the production area, so you will have to go by my words instead.

The facility is divided by 3 main sections, first section is preparing raw materials by way of initial inspection and through cleaning. Second is machining and finishing of parts such as the barrel, receiver, slide, etc. Last is the final assembly and inspection of the firearms.

After showing me the bins full of rectangular aluminum blocks, Martin took me to the hammer forging machine. To my surprise the giant machine is actually not is loud as I thought, as I was told hammer forging process creates a lot of noise. The staff working at the station showed me a finished barrel with it signature spiraling marks in bare exposed steel. I picked it up and it feels cold in the hand. He then showed me how he checks the rifling for any imperfection and uses a dummy round for checking the headspace. The barrels will then be checked again individually at a different station using a boroscope before test firing. It was amazing to see how the machine stretches the length of the unfinished barrel to almost double its length due to the hammer forging process. They were in the process of supply a contract of AUGs so they were busy making those barrels. The AUG barrels are the only rifle barrels that get further machined down after hammer forging.

Martin then took me to the machine that applies the special Mannox proprietary finish. It’s a patented process by infusing the surface with gas vapors resulting a matte finish that is highly resistant against scratches and corrosion. On the machine there is a rack full of the M series of pistol slides after finishing

We walked by a station that has bins stacked with AR15 lower receiver forgings ready to be machined and turned out this is the new STM 556 which is based on an AR15 featuring a quick change barrel system similar to the AUG. The rifle will be offered in 7 different barrel lengths ranging from 11.5” to 22”. The monolithic upper receivers were in other bins waiting to be machined as well. I was shown a machined and anodized upper receiver for comparison. Unlike an AUG, it is designed to accept any M4/M16 magazines. I believed this rifle was announced back in 2014 and they finally got around to put it into production.

In the assembly area, there were skilled technicians carefully assembling trigger assemblies to the receiver then to the stock. Here there were stacks of polymer stocks for the Scout in black, mud and green and the SSG Carbon in grey. It was interesting to see that the assembly process was a fairly manual procedure as each qualified technician inspects the rifle and make sure everything works as designed. It’s also worth to note that there are many configurations for each firearm, there are many stock options, various barrel lengths, calibers, as well as trigger options. The options are basically limitless. So to my surprise they do have a lot of expensive high precision machinery but each firearm is still carefully assembled and checked by humans like a Rolls Royce. It was also interesting to see as much female staff as there were males. Looking at the stocks, Martin pointed out that they also do hydro dipping to create whichever look you desire on the firearm.

All firearms go through an accuracy test, if it cannot achieve expected accuracy (for rifles they have to shoot sub-MOA), they will change the barrel and try again, and if the rare occurrence that it fails they will simply cut up, destroy and dispose the firearm. Of course like most European made firearms, it comes with a test target showing the result of the rounds fired during the test.

While at the test firing area, Martin picked up a rifle from the end of the rifle rack which turned out to be the brand new SSG 08 A1. He said they are currently in production fulfilling a contract for the Norwegians. I was surprised to see it comes in black and in longer barrel length than what was shown in the Steyr Mannlicher brochure which is shown to be offered only in 20” barrel and in RAL8000. The main improvements of the A1 over the original SSG 08 is the flat top rail that goes all the way to the front of the chassis which is designed for night vision attachment in front of the scope. It has a new folding stock which has adjustable length of pull (LOP) without any tools. To adjust the length, press the button on the far left side to release the lever lock. Once the lever is pulled all the way down, you can then press and hold the stock adjustment button and pull the stock back. Martin said they can make it in any colour and all the various barrel lengths which are 20”, 23.6” and 27.2” based on customer request.

I asked Martin regarding to other lesser known advantages of the current SBS (Safe Bolt System) action over the older SSG 69 action featuring rear locking lugs. He said one of the reasons why they had to discontinue the SSG 69 is the rifle cannot be put on safe once it is cocked. This is a problem for hunters who need to have a round chambered and be ready to fire with a quick press to disengage the safety without startling the animal.

The last but most memorable part of the tour was to shoot the AUG. I made a special arrangement with Oliver that I would love to shoot an AUG in full auto as I have never shot one before, not even in semi auto.

It’s truly unfortunate that this rifle is banned by name in Canada. At the test room Martin loaded up a mag into the AUG and passed it onto me. I was able to fire 2 full magazines and made beautiful music. It was simply wonderful. It had manageable recoil due to its bullpup configuration and rate of fire at 700 round per minute made it very easy to shoot.

I was truly overwhelmed by my delightful experience at the factory. Steyr Mannlicher continues to innovate with new and interesting designs and employing modern manufacturing methods while maintaining a group of skilled technicians for assembly and quality control. Each technicians are passionate about their work, as they have many years of experience working at the facility. I hope you all enjoyed my experience as much as I did.

Your Privacy Choices

Your Privacy Choices