It just so happened that I found myself in Atlanta, Georgia for a wedding and had a bit of time to kill. Instead of spending some time getting to know the city or eating at the original Chic-Fil-A, The Dwarf House (cue the jokes about how appropriate that is for me), I decided to give Gary Ramey with Honor Defense a call. Gary offered to give me a tour of their facility and he even might let me build my own gun.

Done deal. After all, it was only a 45-minute drive.

When I pulled up at the nondescript building, I wasn’t quite sure that it was the right place. There were no signs that guns were being built or even a sign on the door. I called Gary to make sure I was where I needed to be when I saw him frantically waving through the window. I guess we were in the right place.

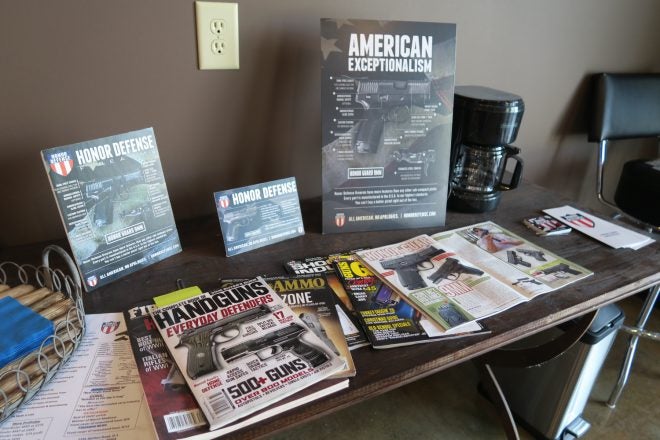

Once we got inside I was met by Gary and the family dog Bentley, a giant Great Dane. To start off I poked my head around the office area and found that the folks at Honor Defense hand onto just about every bit of press they have received. After all, all but one reviewer had wonderful things to say about the Honor Guard, including myself. I also found that there was patriotic paintings, flags, and other wall hangings everywhere. As we will find out later, pride in country is something that is very important to everyone employed at Honor Defense.

After we sat down for a presentation from Gary about how they got their start, why they decided to go the direction they did, and some of the glowing reviews they have received we stepped out for lunch at Gainsville, Georgia’s most genuine hamburger joint, The Collegiate Grill. After a wonderful meal we all headed back to Honor Defense and was given a proper tour.

Mind you their facility is only 4,000 square feet, they still have been able to pack quite a lot into a small space.

Starting with Richard the lead engineer’s office we found parts everywhere and more QC tools than I can name. When I walked into his office he was busy measuring firing pins to make sure that they fit into their specs perfectly. Richard told me that every single part on the Honor Guard is measured or goes through some rigorous QC procedure to allow them to produce the best product possible.

I was impressed that Richard spends the time to test every one of the critical parts on the Honor Guard with high-end equipment. Below is the pile of firing pins and the tool used to measure them. I was told that the tool was accurate to about 1/3 the width of a human hair.

I also stumbled on some Honor Defense history like parts of the prototype pistol. The grip below was a very early prototype that eventually became the grip shell used on the gun. I was told that there were 9 prototypes before they felt they had the shape and texture good enough.

Once Richard had told me enough engineering stuff to make me feel light headed I found that Gary had broken out his travel case of sample guns. The two slides at the bottom are for some guns that he is producing for charity auctions and not for public sale, I think that the grey camo slide may be coming up for auction soon. Gary offers up a pistol now and again for auction with the proceeds going to that charity, I love to see gun companies give back like that.

I told Gary that he need to offer the Cerikote finishes as an OEM option, I think they might do well. Heck, I kinda wanted to grab the flag slide and run like hell but I am pretty sure that Bentley the dog would have caught me with his giant, horse like stride.

The case held just about every variant of Honor Guard on the market and a few new ones that haven’t been on the market long like the long slides.

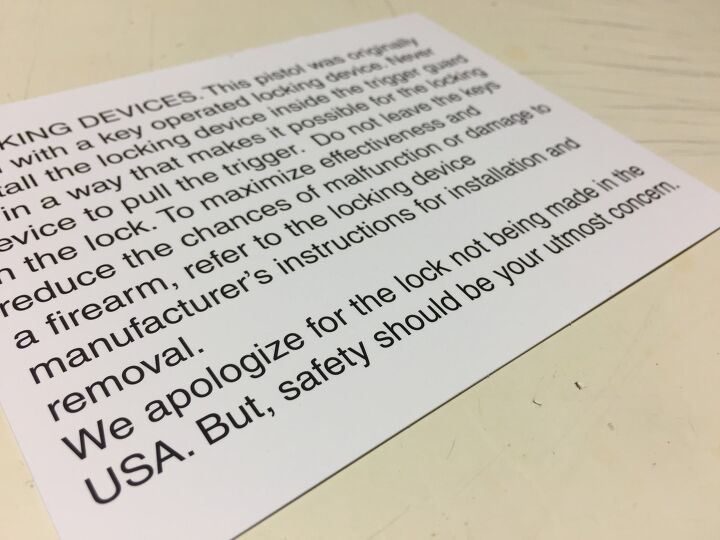

Like I previously stated, Gary and the rest of the Honor Defense crew take patriotism to a new level. They even tried to source an American made gun lock for the Honor Guard and when they couldn’t, they included an apology with every pistol.

While I was there Gary informed me that they were not only going to be rolling out a new salesforce for the Honor Guard, but also are introducing a stocking dealer program complete with all the decals, banners, stickers, and information a dealer might want.

It was about then that Bentley the dog decided it was time to head out to the assembly floor for the next phase of the tour. Who was I to argue with a monster?

Walking onto the assembly floor I was blown away at how little space is required for the amount of pistols they ship. Only about 3,000 square feet is dedicated to building the guns, and in reality only about 1,500 would be needed. I was told that while this looks unassuming, they do ship anywhere between 100 and 250 pistols PER DAY. Every one of them is hand built, test fired, and packed by hand.

You might notice the table full of empty boxes. Gary kept every box they used when torture testing the first production Honor Guard and had laid it out for TFB to see. I don’t recall the total round count, but I would wager a guess that this is more ammo than most people will shoot through the ownership of a single gun.

here you see the cage where they keep most of the controlled parts and the assembler workstation. The long white table was filled with about 120 Honor Guard pistols just prior to me taking the photo.

Unlike other companies, Honor Defense assembles every pistol by hand. The only power tool used for the assembly process is a battery powered screwdriver used to install the front sights. I was quite surprised at the lack of machinery in the building and a touch overwhelmed at the number of pistols they are capable of building by hand each day.

The small parts were carefully stored in labeled bins. While my camerawoman was on her Union mandated quarter hour break, I wandered around the facility and took some photos of the parts waiting to be built into pistols.

That kinda concluded the tour portion of the visit. The other reason that we were at the Honor Defense facility is to not only see how they put together the Honor Guard, but to build one ourselves. Since that is going to be of a long write-up, I am going to save that for a separate post.

What I was getting at is the more expensive parts are kept in a locked cage. This is where we find the slides, barrels, striker assemblies, and other costly parts. The only reason I was able to snap this photo is they needed to get a barrel for the pistol I was building, otherwise the cage would have remained locked.

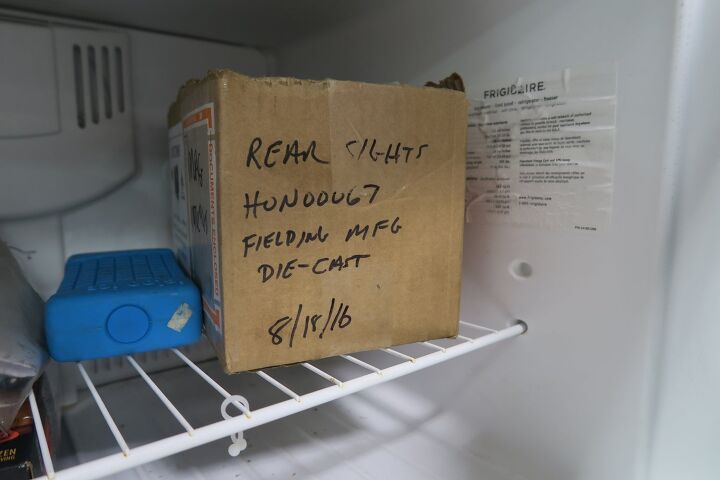

The most surprising thing that I found during my tour. How they cheat the system a bit when installing the rear sights. The box below held enough sights to keep the team building for months, and is kept in the freezer to make the metal contract just a touch. This allows Honor Defense to fit a rear sight that when warm would be a touch too big to fit into the dovetail cut and maintain a good, tight fit.

That table that I mentioned earlier held about 120 Honor Guards when we got to the facility. Not only is the Honor Guard hand built, but each one is packed by the same people that build the guns. Gary said that Honor Guard ships out around 600 pistols per week now. Seeing as it is a new gun to the market from a young company, that is quite the feat.

The in-house proofing setup was nothing short of interesting. Each gun that the Honor Defense team builds is proof tested with some Double Tap +p proof loads. Since they don’t have a range on hand the proofing load is fired into a bullet bunker from a ransom rest where the pistol is aimed by the man testing it and the aim is verified by another employee before the shot is fired.

I had to admit, I really wanted to test a few pistols. The assembly team and Gary said that I could and let me test fire about a dozen brand new Honor Guards. Firing the actual first shot out of a firearm is something I haven’t done before and thought was pretty neat. After all, every new gun I have bought has been proofed before I get it, now someone out there will get a pistol that was proofed by me.

So if you bout an Honor Guard and weren’t quite sure why the case was painted red, that is to signify the proof load and warn reloaders to not reuse that case.

Soy you might be wondering after all that, how are they building the guns if there are no machines? How long does it take? Best guess after timing someone building a gun is that it takes about 8 minutes to build from the ground up. I noticed that most of the assemblers worked on several at the same time and went from part to part in order to stay efficient.

It was right about then that Bentley the dog decided work time was over and he wanted to play. We took that as our cue to head back to the hotel, we wouldn’t want to interrupt one of the happiest beings on the planet while playing with his box.

Keep an eye out for the next post I put up about Honor Defense where they let us build our very own Honor Guard. When I had the pistol in for review I found it to be very good and quite serviceable. The Honor Guard had some wise features, but it still looked a lot like a Shield.

Once we got elbows deep into the gun, it is quite easy to see it is nothing like an M&P Shield. As you will see, it is far more like a simplified P320 that is hand built. like to thank Gary, his family, and the rest of the Honor Defense team for their hospitality and allowing us to come tour the facility and become assemblers for a day. On top of that, We happened to become certified Honor Guard armorers at the same time! What better way to learn than assembling a few pistols and taking them apart?

I want to thank Gary, his family, and the rest of the Honor Defense team for their hospitality and allowing us to come tour the facility and become assemblers for a day. On top of that, We happened to become certified Honor Guard armorers at the same time! What better way to learn than assembling a few pistols and taking them apart?

Learn more about Honor Defense at their website HERE.

Your Privacy Choices

Your Privacy Choices