Today we know the Kalashnikov family of rifles as one of the most successful and reliable weapon families ever designed. Even as the rifle’s legend has begun to be peeled back, the weapon’s reputation for reliability is still largely unquestioned, and many consider it to be the most reliable individual automatic weapon ever made.

Beyond just its reputation, though, the Kalashnikov is an extremely well-designed weapon that was from the outset optimized for reliability in many ways. The AK incorporates more design elements intended to enhance its reliability than probably any other production automatic rifle that I know of, and these features are doubtless what has allowed the legend of Kalashnikov reliability to grow beyond the reality (however well-designed they are, Kalashnikovs do in fact jam sometimes!).

Despite its reputation, I don’t think the reasons for the AK’s reliability are fully appreciated, so I wanted to take a little time to go over the exceptional elements I have identified in the rifle’s system that I think allow it to be such a consistently good performer.

1. Operating mechanism design: Anti-preengagement, mass ratio, and more

The AK’s fixed piston, two-lug rotating bolt operating group has become one of the most revered elements of the weapon, but it still remains poorly understood in the common literature. For example, the fixed piston operating rod style action is often called a “long stroke” gas piston, even though the propellant gas does not impinge on the piston for the entire length of the operating rod’s travel (it is vented soon after the piston begins to move to the rear). Therefore, we should take a closer look at why the AK’s operating mechanism has stood the test of time.

Probably the three biggest assets of this operating group are its anti-preengagement (APE) mechanism, its high mass ratio, and the generous clearances around the moving parts. I’ve discussed the value of having a mechanism that prevents premature bolt lock – which I’ve called by the somewhat clunky name of “anti-preengagement” – before, in my post on the genetics of the AK’s design, and in my critique of the M1 Garand’s design. In the latter post, I explain:

For an autoloading weapon with a locking bolt mechanism that is actuated by the compression of the bolt and carrier (as in most designs), it is important that the locking mechanism not be able to lock too early. In many designs, this is done by simply not giving the mechanism room until it is in the right position for locking.

For example, in an AR-15, the bolt is prevented in its rotation by the inside of the receiver, which bears against the cam pin. Once the bolt has reached the end of its travel, a special cutout in the side of the receiver, visible from the outside as a small “hump” on the side of the receiver, allows the cam pin to rotate and the bolt to engage. While this system works very well, it means that the bolt is trying to engage throughout its travel forward as the force of the ammunition and friction of the magazine tries to force it rearward. This induces friction between the moving parts and the receiver, which must be overcome for reliable functioning.

There is a more elegant way to overcome this, which has been described as an “anti pre-engagement mechanism”. The Garand features this. Essentially, instead of the locking element trying to actuate throughout its travel in the receiver, the Garand features a shelf in the operating rod:

The flat surface lightly highlighted in red is the anti pre-engagement mechanism, which supports the bolt during operation, preventing it from trying to rotate against the cam track. Image source: gunauction.com.

Another flat surface on the bolt lug rests against this shelf during cycling, preventing the bolt from trying to make a turning move, and reducing friction during operation. Just before locking, a bump in the receiver knocks the bolt out of alignment with this shelf, allowing it to complete its rotation.

The AK’s cam track and cam lug design are copied directly from the M1’s, and therefore its APE mechanism works exactly the same way, giving it the same low-friction cycling characteristics as the M1.

In locked-breech firearms, the moving parts group needs to have enough momentum to open the action, initiate extraction and ejection, and then on the return stroke feed the next round and lock it in the breech. One might assume that the ideal way to accomplish this is with a light moving parts group moving very quickly, but there is a limit to how fast the operating group can move. The lighter the moving parts group is, the stronger the return spring must be to give it enough momentum, and the harder the weapon will be to charge. In addition, the faster the moving parts group is going, the stronger the magazine spring must be to move the cartridge stack into position in time for feeding, and the more quickly the weapon will wear out.

The correct solution to this problem is to optimize the moving parts group’s mass ratio, which is the ratio of the operating piece (bolt carrier or operating rod) to the locking assembly (breechblock and locking piece, or bolt). Having a favorable (higher) mass ratio allows the operating piece to lose the momentum of the locking assembly during locking, and still complete its forward travel with plenty of momentum to spare.

The M1 Garand, which provided much of the mechanical basis for the AK, has a relatively poor mass ratio of 1.75 to 1 for its operating rod vs. its bolt, while the AK family has an excellent mass ratio of about 5.6 to 1. This means that the AK’s operating group has ample momentum to complete the operating cycle positively every time.

Previously, we talked about the principle of “underslide”, where dwell time is built-in to the unlocking piece of a locked-breech automatic firearm to allow pressure to drop in the barrel before extraction occurs. Most, if not all, serious studies of automatic firearm mechanics identify this feature as a major boon to the extraction reliability of automatic firearms that have it. While the American AR-15 rifle (which is excellent, nonetheless) possesses virtually no underslide, the Russian AK series possesses significant underslide to the tune of about a half inch. This means that the AK gives its ammunition slightly more time for the pressure in the chamber – and therefore the force on the case walls – to lessen, aiding extraction.

To wrap this section up, let’s talk about the operating group in general, and especially the bolt. One of the lessons that Kalashnikov very astutely learned from Garand’s M1 rifle is that whenever possible wide clearances should be given to a rifle’s parts. This allows parts to move even when debris, dirt, and fouling have interfered. Colonel Roy Rayle relays John Garand’s experience in Random Shots: Episodes in the Life of a Weapons Developer, on page 31:

On one of my trips with John Garand to see Dave Mathewson in New Haven, with Stan Fish driving, I asked John if he could explain to me why his rifles got through sand, dust and mud so much better than other rifles. He said the answer is simple. Other rifles use a bolt carrier with tight fitting surfaces between carrier and bolt, as well as between carrier and receiver, while his rifles use no carrier. The only tight fit for his rifle is at unlocking; once the bolt is unlocked there is only a sloppy fit between bolt and receiver, so his rifle has no trouble in back and forth motion in those tests.

Kalashnikov studied the M1 rifle closely, but never met with John Garand (certainly not before the production of the AK-47). The fact that he was able to recognize and incorporate this principle of loose fit from just observation, not to mention the fact that he combined that principle with a bolt carrier – which John Garand was unable to do – speaks highly of his talent as a designer, and as an appreciator of the designs of others. Indeed, this appreciation for Garand’s work becomes overwhelmingly obvious when reading Edward Ezell’s landmark work on Kalashnikov:

Kalashnikov talked at length about how he did his work, and to whom he was indebted for his design ideas. For example, he showed us his 7.62x41mm self-loading carbine, which he had developed in 1944 and 1945. He retracted the bolt and, pointing to the Garand-type cartridge follower, he told us that this weapon used a 10-shot en bloc clip of the M1 rifle type. Kalashnikov told us that John Garand was one of his design mentors, and that he borrowed several design features from the M1 rifle and M1 carbine (which he mistakenly believed was also designed by Garand). I was impressed by Kalashnikov’s frank willingness to acknowledge his debt to other designers, a trait which I attribute to his being very secure in himself regarding his position in the world of small arms designers.

…

At one point curator Natsvaladze commented that John Garand had not created as many different weapons as had Kalashnikov. Mikhail Timofeyevich snapped back at him. “When you get it correct the first time, you don’t spend your time designing weapons for a museum!” Garand was obviously one of Kalashnikov’s heroes, and no one should question the accomplishments of his heroes!

I take this substantial aside on Kalashnikov’s relationship to John Garand to point out that just as some do not know Kalashnikov produced anything beyond the AK-47, Kalashnikov himself was not aware of John Garand’s substantial corpus outside of the M1!

Kalashnikov’s bolt design – which is common to his self-loading carbine, as well as the AK-46 and AK-47 assault rifles – was substantially influenced by John Garand, yet also improved. Where Garand was unwilling to use a bolt carrier, Kalashnikov designed a bolt carrier that provided the same clearances as Garand’s masterpiece, yet which controlled and protected the bolt better than any of Garand’s designs. Also from Garand, and virtually by extension, Paul Mauser, Kalashnikov also retained the feature of chamfered locking lugs on the bolt. These specially shaped lugs were an innovation made during the height of the military bolt-action rifle, and most commonly seen on Mauser’s 93 and 98 model rifles.

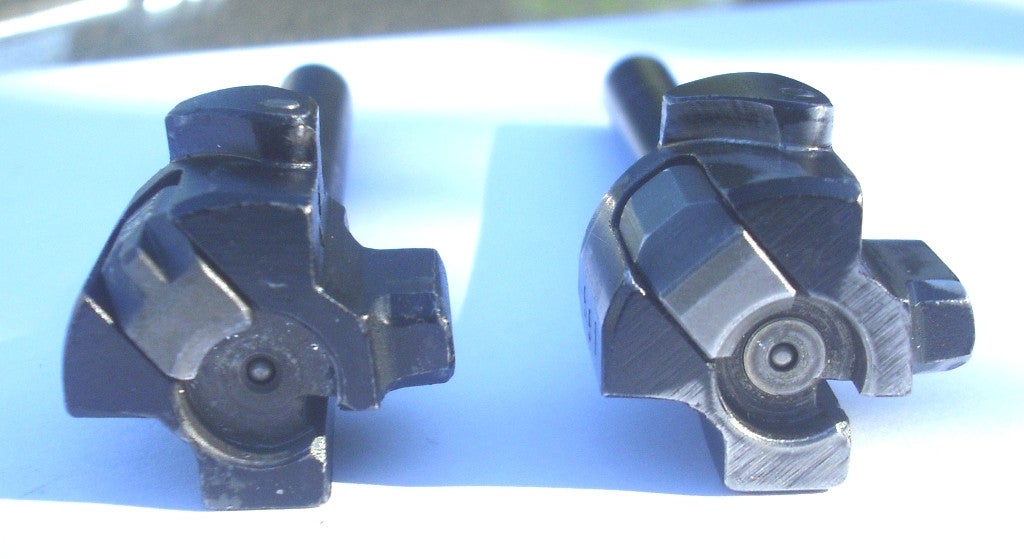

Two late model AK bolts. Note the chamfered and shaped locking lugs. Image source: forum.saiga-12.com

What does lug chamfering do, though? Well, in the original bolt-action application, it allowed for primary extraction, which refers to how the bolt of some bolt-action rifles can retract during the lifting portion of bolt handle movement. Essentially, this movement allows the shooter to break a stuck case free using the mechanical advantage given by the bolt handle. As the bolt handle is lifted up, the bolt rotates and then moves backward slightly in its chamfered lug recesses, which breaks the case free of a grimy chamber.

An M1 Garand bolt; note the heavily chamfered locking lugs, just like the AK. Image source: thefiringline.com

In the AK, we don’t see much of this effect directly. Because the bolt carrier acts on a lug just a short distance from the axis of the bolt, the force of primary extraction is probably limited. However, the chamfering probably does ease the lugs into and out of their locking recesses during cycling, freeing up that much more energy for both feeding and extraction. I think it is appropriate to consider the chamfering of AK locking lugs as a “luxury”, but that to me illustrates just how focused Kalashnikov and his team were on making the AK a reliable design, versus an economical one, especially when this is contrasted to the mechanically simpler AR-15.

We have now very nearly reached 2,000 words, and therefore should take a little break. Fear not, though, tomorrow we will be back, examining the rest of the Kalashnikov’s best features which make it the most reliable automatic rifle in the world!

Your Privacy Choices

Your Privacy Choices