The Cold Hammer Forged marking ‘CHF’ is stamped into millions of rifle barrels around the world. And while it’s not the only way to make a barrel, for AR15 patterned rifles it is likely to be the most common*. But what exactly does that CHF mark mean? Let’s take a brief look at one part of a type of barrel-making process.

* Button rifling is the most common AR barrel manufacturing process.

Cold:

Ok, not exactly cold – by ‘cold’ we mean ‘not hot’. The CHF process takes place at room temperature, and even though the metal will warm up under pressure and work, it’s nothing compared to a temperatures used in other forging processes. For example, hot forging will usually take place at 80% of the metal’s melting temperature (red hot).

Hammer:

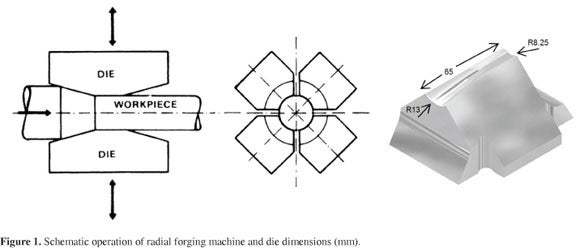

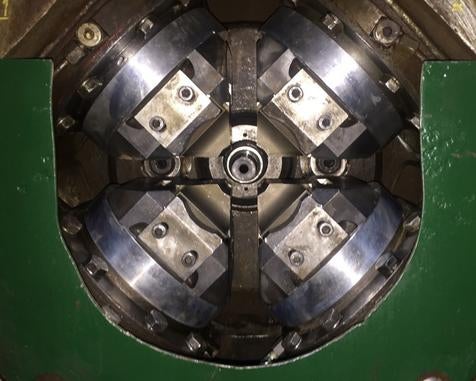

Hopefully you aren’t picturing a framing hammer and a 10 penny nail. The hammers used in the CHF process are heavy pieces of metal that are shaped and angled to pound the barrel blanks into shape (see below).

Forging:

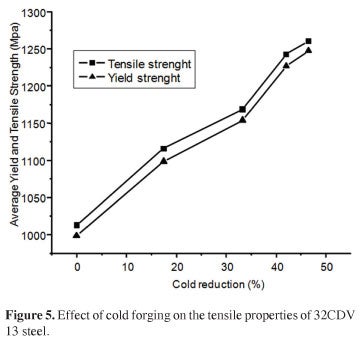

Not only does the forging process shape the barrel, but it strengthens it as well. The repeated blows by the hammers align the molecular “grain” within the metal, increasing rigidity and strength.

The last, but important, part is that a mandrel and reamer are used to form the chamber, bore and rifling as the hammers pummel and elongate the barrel.

Credit: scielo.br

Tensile strength increases with CHF processes (32CDV 13 steel used as an example).

Credit: Scielo.br

CHF a shotgun barrel:

Total Materia – http://www.totalmateria.com/page.aspx?ID=CheckArticle&site=kts&NM=277

The cold forming process is similar to the cold heading process, however, the process uses vertical presses instead of horizontal cold heading machines. The cold forming process is also volume specific and the process uses dies and punches to convert a specific “slug” or blank of a given volume into a finished intricately shaped part of the exact same volume. The cold forming process generally compliments the cold heading process by adding more intricate shapes to the cold headed blank.

Cold Hammer Forging machine:

Credit: SandHammerForging.com

Cold forging is a reliable and cost efficient process. The main advantages are the following:

- savings in material and final machining,

- high productivity,

- excellent dimensional accuracy and surface quality of cold extruded parts,

- improvement of mechanical properties of extruded parts

- favorable crystal grain flow increases toughness.

All About Barrels:

The fact that hammer forging works is attested to by the fact that most of the major firearms manufacturers use it-Remington, Winchester, Ruger, Sako and Steyr, to name a few. Indeed, Savage may be the only major company that uses button rifling. Obviously, either method is capable of prod-ucing an accurate barrel.

One would think that [hammer forging], especially, would put all kinds of strain on a barrel. I mean, we’re taking about taking a nearly 2-inch-diameter bar of steel about 12 inches long with a hole through its center, and by hammering the living hell out of it, elongate it into a 24-inch-long tube having a muzzle diameter less than one-third of what it was originally. I mean, we’re talking major stress and realignment of the steel’s molecular structure here; that’s why the stress-relieving process is so critical.

Daniel Defense talks about Barrel making:

Want to CHF your own barrel blanks? Good luck – the CHF process requires 50 tons of pressure per hammer. Machines that can pull off that kind of force dont come cheap. That ‘The More You Know’ about Cold Hammer Forging.

Your Privacy Choices

Your Privacy Choices