Being from the industry, it was surprising to see a video pop out on the physical and full machining of an AR-15 lower receiver. The “secrets” to machining the lower correctly and with the minimum amount of machine time are closely guarded secrets by most of the industry. Even a reduction of one minute can mean large swings in margin for a manufacturer. Efficiency is key.

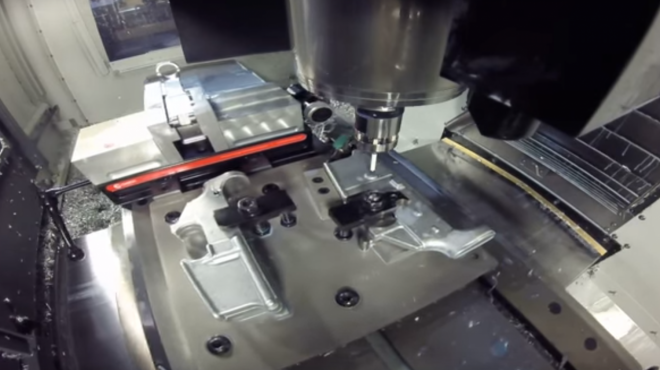

Bucking the trend is Palmetto State Defense, not to be confused with Palmetto State Armory. Instead, PSD has opted to showcase the full cycle in all its glory, including fixturing, cut paths, etc. Surprisingly, Palmetto State Defense opts to broach the magazine well corners directly in their vertical machine (most companies broach separately).

In fact, the fifteen minutes needed to take a lower to 80% is mesmerizing. Its incredible for one to understand the complexity of the cuts and the number of tools needed to complete a “simple” lower receiver from a forging. Of course, billet would take extra time as it would require machining the exterior of the part.

For those interested in “how its done” the video is posted below from the machine spindle’s perspective. Finishing the lower would only be a few more minutes on top of the machining show.

Your Privacy Choices

Your Privacy Choices