This is a the second part of a guest article from our reader Brandon covering the development of synthetic magazines for the AK-47 and AKM rifles. You can read the first part, on metallic magazines, at this link. Thanks, Brandon!

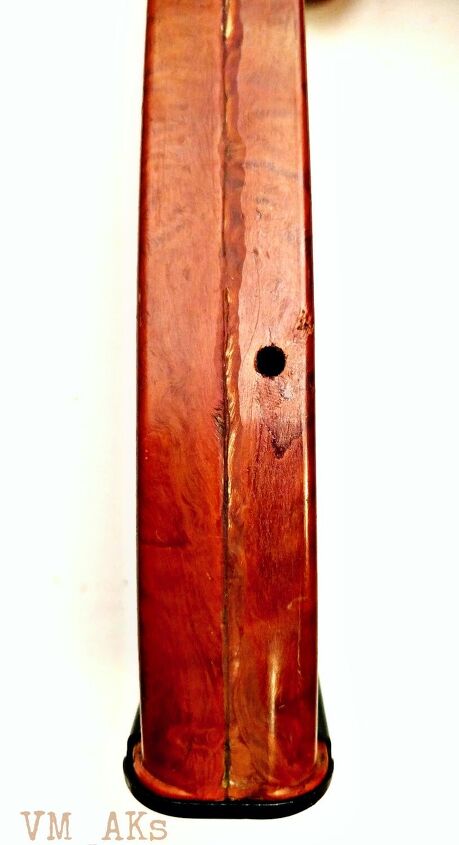

Sometime around 1965-1968 Izhevsk developed the AG-4S lightweight magazine also commonly referred to as the Bakelite magazine. While AG-4S is not technically Bakelite, it is similar and has a similar appearance which is likely why the name stuck. The magazines are produced from a thermoset phenol-formaldehyde resin which is glass fiber reinforced. These magazines are much lighter than any steel production magazine and are still quite durable. You’ll hear many stories of them being brittle and breaking, but in reality, they do not chip and break easily thanks to the fiber reinforcement. These generally feature orange, brown, and red tones and have a marbled, almost wood look to them thanks to the lamination process used to produce them. They were molded as two halves and epoxied together. They all feature steel reinforcement along the body of the magazine and later variants had steel reinforced feed lips as well. The reinforcements can be found by looking for the spots of black paint. They continued this tradition to the present and anywhere the steel would be slightly exposed, it’s painted black over.

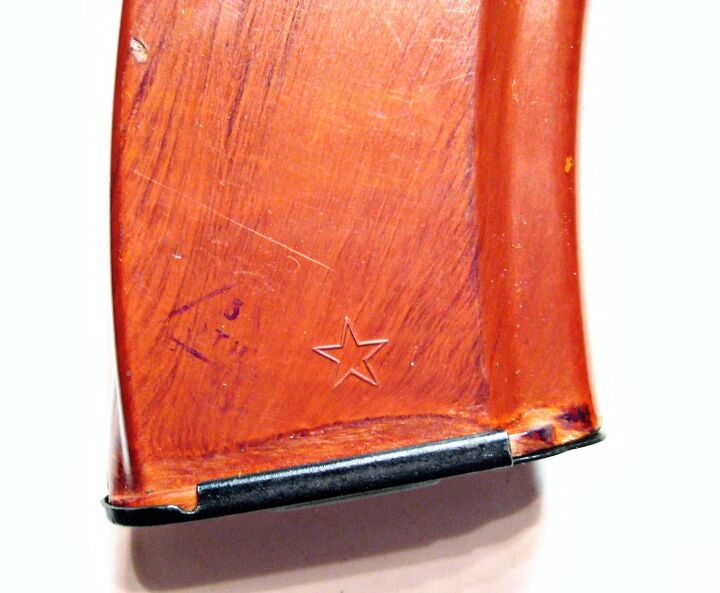

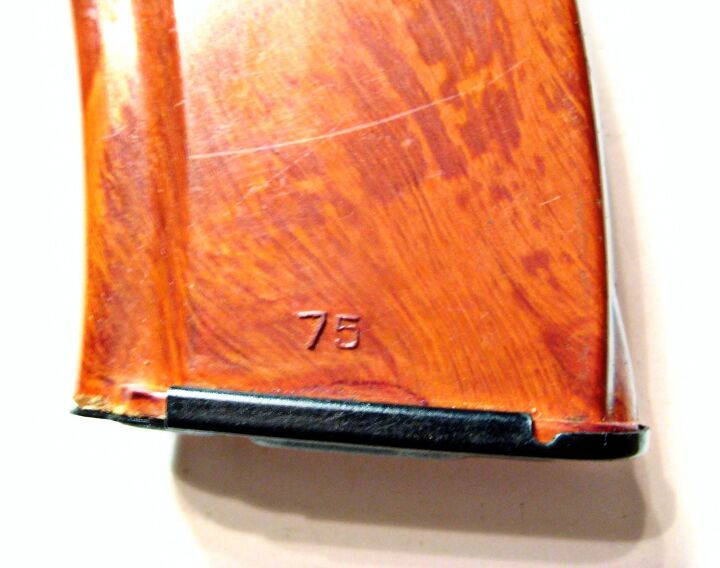

The arsenal marks are molded into the magazine body on the right and they feature ink as inspection stamps. The left side of the magazine features a mold number. Just as with any modern plastics manufacturing, these were marked with mold numbers for many reasons, like keeping track of when a mag was made and if there was a problem with the mold, it’s easier to identify the affected magazines. Once a mold was used up, the next was put in it’s place and was marked with an incremental, consecutive number. Often times the mold number can be helpful on dating a magazine, but the Soviets tended to restart the mold numbers frequently and sometimes for unknown reasons. Generally the lower the mold number, the older, but not always.

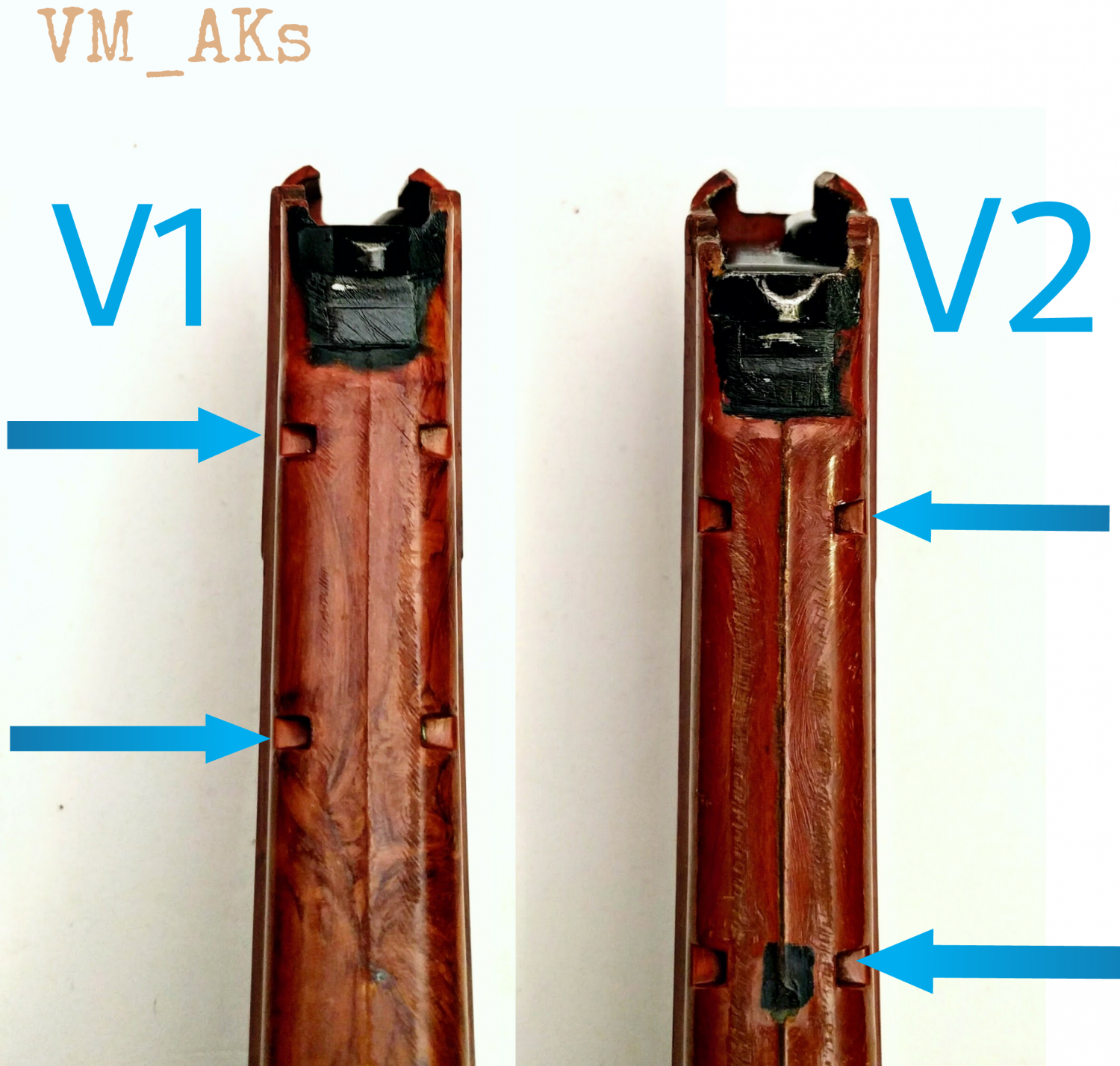

The first variation of these is referred to as the long top due to the top feed lip area mold being elongated and extended further down the body. There are two variation of these. The first having notches on the front closer together while on the second, the notches are much further apart. These do not have steel reinforced feed lips.

The early variations tends to have very unique and attractive marbling. This first photo shows version one on the left, and version two on the middle and right.

The next variation is commonly called the ridgeback and carries over the long tops reinforcement ridge running along the backside, but the feed lip area is shortened. These can be found with or without steel reinforced feed lips. This variation is where the ink stamping becomes more standardized. You’ll find a rectangle with a single Cyrillic character on the top front left side and under that, is the Russian OTK acceptance stamp with a number after. At some point, a small silver stamp with a single Cyrillic character began appearing and stamps on the rear also.

Next came the flat back. The ridge on the rear was eliminated, but otherwise the magazine was nearly identical to the ridgebacks. These all feature steel reinforced feed lips.

The last AG-4S magazine type produced is referred to as a Cyrillic mold number due to mold number featuring Cyrillic characters. These are identical to the flat backs aside from that one detail. The most common is ЦТ and then a number and there are a few that feature a number followed by П.

Tula followed Izhmash production fairly closely in the production of these mags, but have less varation. Tula began production with the long top version one mold and it doesn’t appear that they ever produced a different long top variation. There’s much talk of one, but I have personally never seen any evidence of it’s existence. These mags tend to be very bland as far as texture. A small silver Ч ink stamp is present on these on the lower left side.

Tula went to the ridgeback just like Izhmash after and aside from the diamond Tula inspection stamp and arsenal mark, they are basically identical.

They appear to have gone to their first Cyrillic mold magazine before Izhmash did. These still feature the ridge on the rear and have an A as a suffix on the mold numbers.

From what it appears, the last AG-S4 produced by Tula was a flat back Cyrillic mold number. The ridge was eliminated from their design, just like the Izhmash flat backs, and these feature a B as a suffix on the mold number.

At this point its getting close to the 1980’s and the AK-74 is in full production and the AKM is being slowly phased out. Izhevsk produced two other small production magazines before 7.62×39 stopped being general issue. One looks very similar to the AG-4S magazines, but also resembles the Czech VZ-58 furniture that’s commonly called beaver barf. There is much speculation on the material from which this magazine is made, but without getting one in my hands, it’s hard to say. There were many versions made of this material including the 20-round 5.45×39 magazine. The other is the elusive plum waffle. Made of a deep purple, glass-reinforced polyamide; around 5,000 of these were made and issued and seem to be the last general issue 7.62×39 mag produced, although they may or may not have been issued by the Russians. The how, why, and when they were used, doesn’t seem to be well known, but most examples come from the middle east via soldiers bringing them back. I’ll discuss more on the make-up and development of the plum magazines once I get to the AK-74 magazines.

The following photos are courtesy of Justin B. And gregsthe1:

The final and most recent 7.62×39 magazines produced by the Russians were solely made by Izhevsk and were made mostly for export. Around the early 90’s the AK-100 program came to fruition beginning with the AK-74M and on to the AK-101 through 105. The magazines were produced for the AK-103 and 104 and are generally called AK-103 magazines, and are comprised of a black glass fiber reinforced polyamide. The first variation featured a ribbed side and the second was smooth and thusly called the slab side 103 mag. The slab side is marked “7,62×39” on the side which denotes it for export. Special ops do still used 7.62×39 and can been seen with the mags, but neither of these were ever standard military issue.

Your Privacy Choices

Your Privacy Choices