We’ve discussed a lot of different rounds in this series so far, but today we’re going to discuss a round that actually has a shot of being adopted (at least in some form) by the United States military as a next-generation small arms ammunition configuration. That round is the .264 USA, developed over the past few years by the Army Marksmanship Unit (AMU).

The .264 USA is a direct response to combat in Afghanistan, where the primary threat to US infantrymen was emplaced 7.62x54mmR general purpose machine guns engaging Allied forces at long ranges, beyond where troops armed with 5.56mm carbines could effectively return fire. As a result, the .264 USA is a very large cartridge by intermediate caliber standards, measuring over 66mm (2.6″) long, and producing nearly 2,700 Joules of muzzle energy. Because of its size, much of the same analysis I wrote regarding the .280 British caliber of the late 1940s will be applicable to this caliber as well, something which we’ll get into more detail on later.

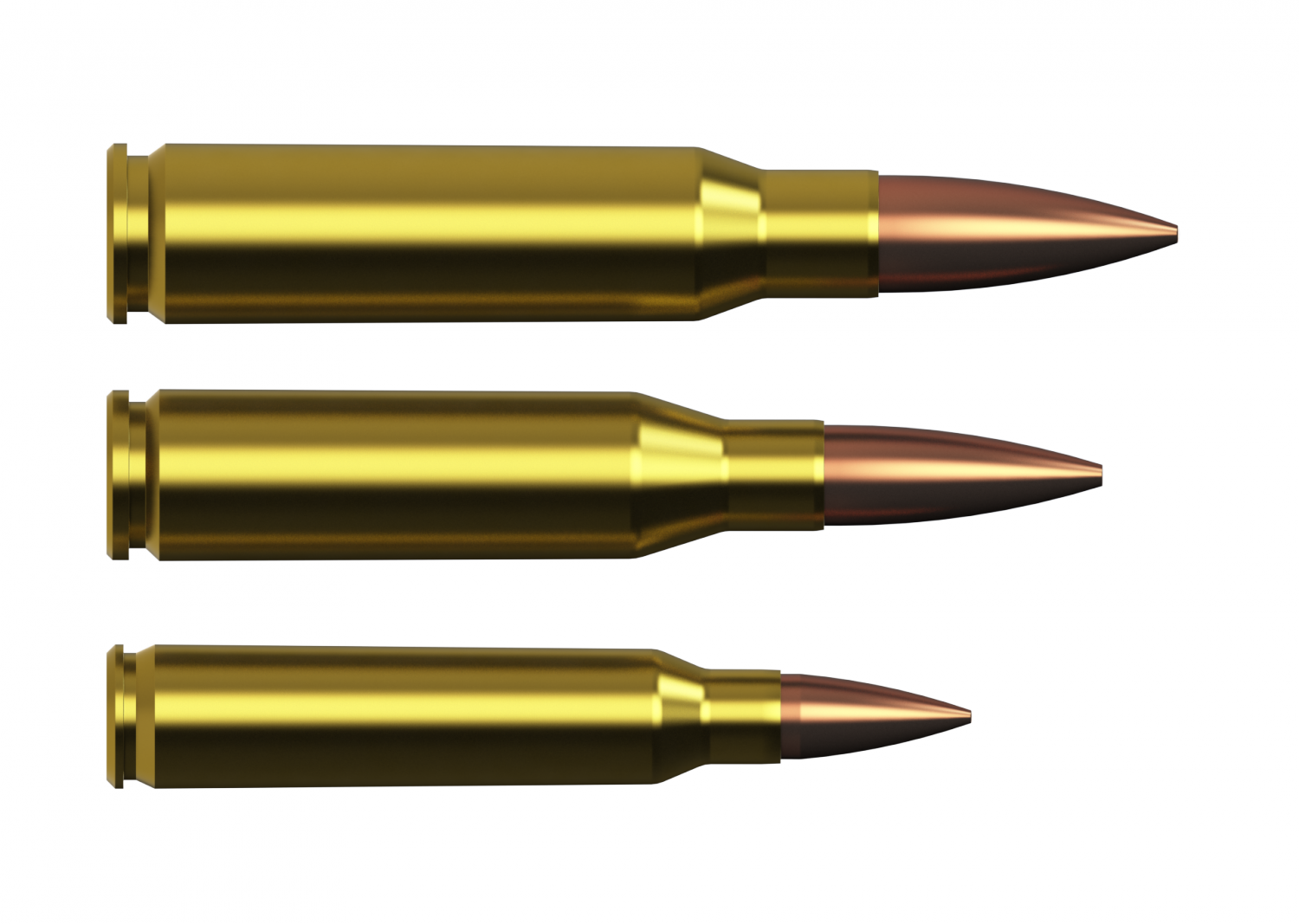

The .264 USA (center) compared with the 5.56x45mm (bottom) and 7.62x51mm NATO (top). The .264 USA was designed to provide longer range than the 5.56mm, while reducing weight and size versus the 7.62mm.

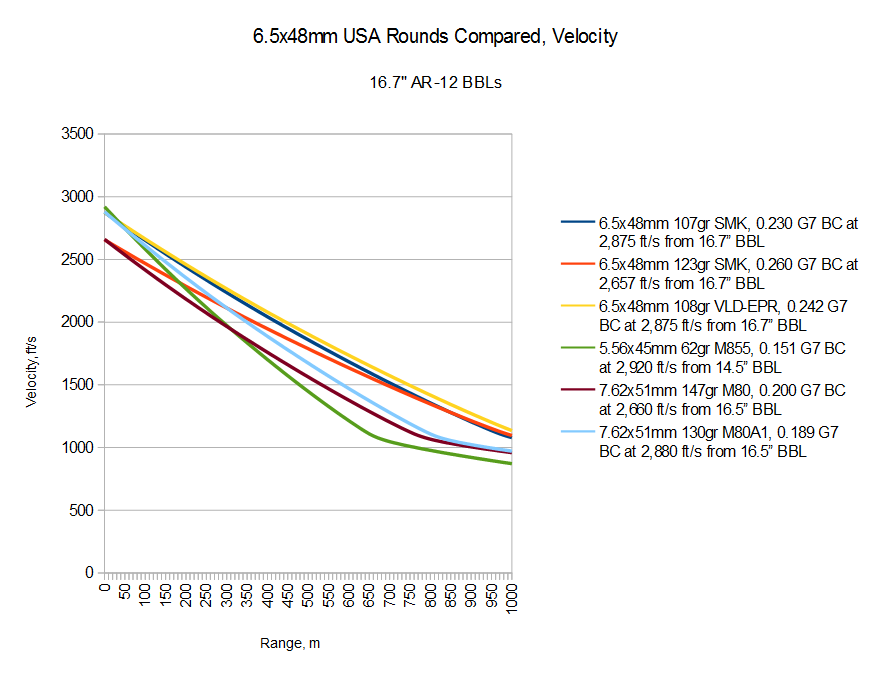

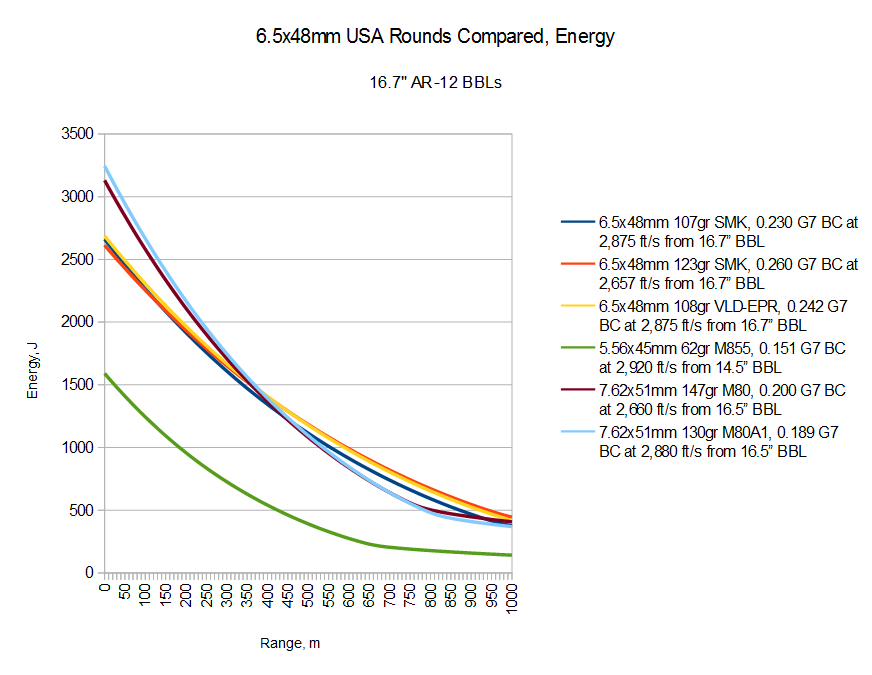

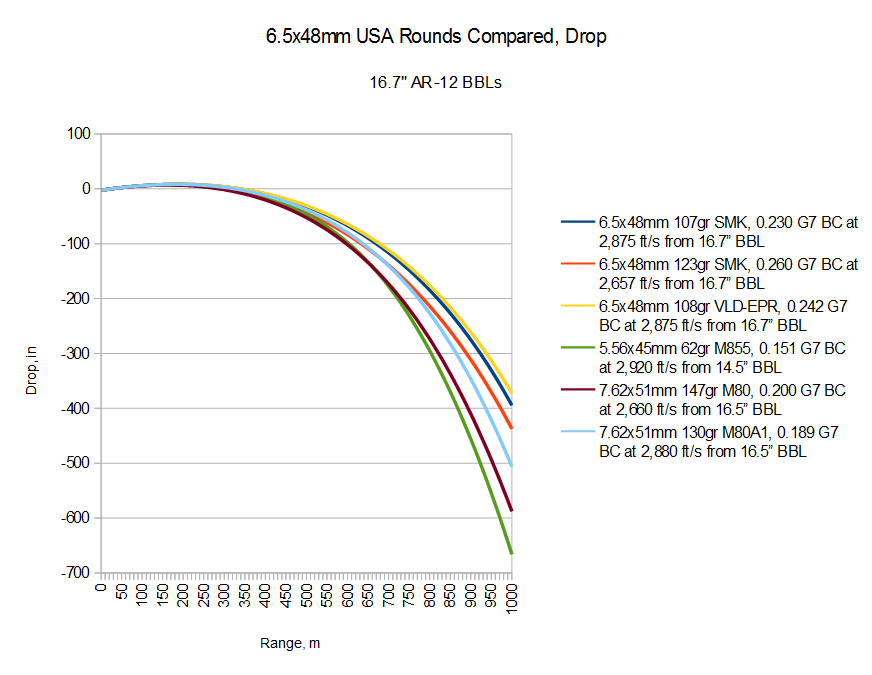

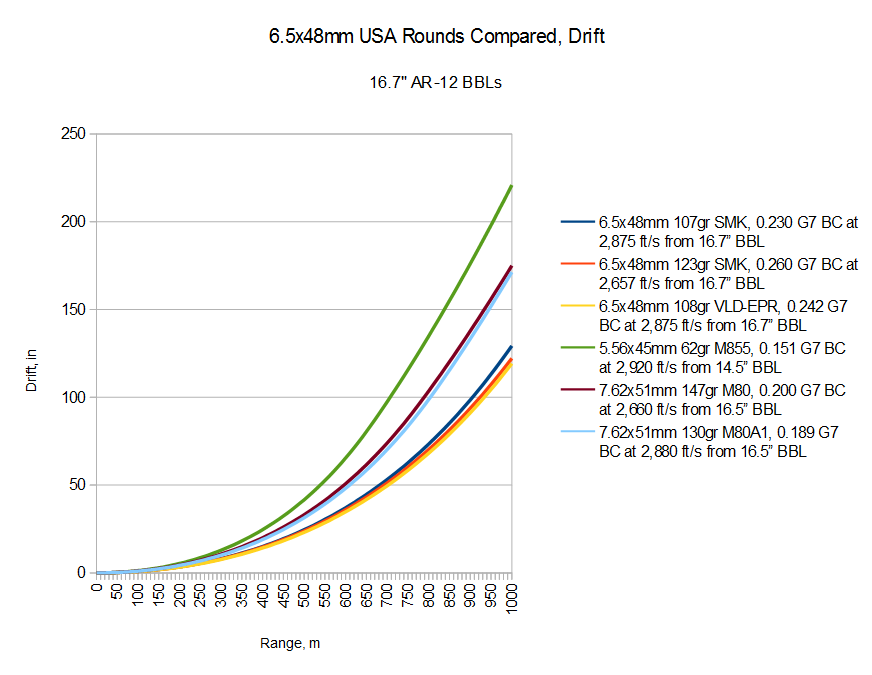

Like larger 6.5mm rounds designed for long-range shooting competitions, like the .260 Remington, 6.5 Creedmoor, or 6.5x47mm Lapua, the .264 USA is designed to use long, low-drag projectiles, giving it ballistics comparable to or even superior than the larger and heavier 7.62mm NATO round. These excellent ballistics can be seen in the graphs below, alongside data sets for 7.62mm and 5.56mm. In addition to the 107gr and 123gr Sierra MatchKing bullets specified in the solicitation, I have also thrown in a 108gr (7g) lead-free EPR-type projectile with a finer shape and higher ballistic coefficient, to illustrate the maximum potential of the round.

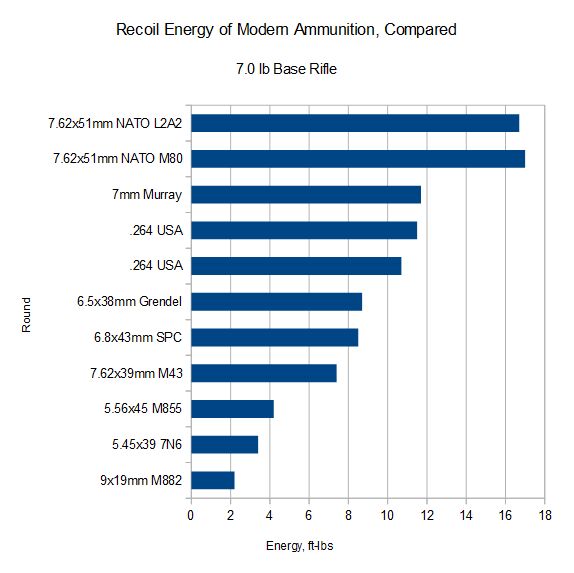

From this perspective, then, the .264 USA is a knockout hit; with a higher ballistic coefficient than the 7.62mm NATO, and comparable velocity to the 5.56mm (in 107gr form), the .264 handily outmatches both in velocity and energy retention, flatness of trajectory, and resistance to wind. However, like the .280 British discussed previously, the .264 USA’s large size and considerable propellant load mean it produces much higher recoil than other intermediate calibers. Below is a chart comparing the recoil energies of different rounds from the same hypothetical 7 lb (3.175 kg) firing platform:

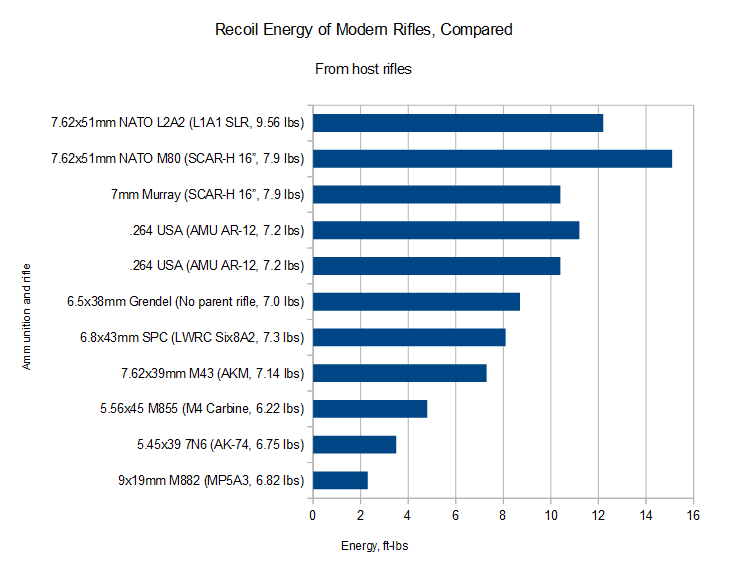

This shows that, in an apples-to-apples comparison, the .264 USA produces considerably greater recoil forces even than other powerful intermediate calibers like the 6.5 Grendel and 6.8 SPC. For additional perspective, the chart below shows the same calibers fired from different real-life host weapons, to give a sense of how these weapons would compare to each other:

We can see that from the 7.2 lb (3.265 kg) “AR-12” (not to be confused with the AR-12 rifle predecessor to the AR-18 developed by Armalite in the 1960s) developed by the AMU for the .264 USA, the .264 USA generates nearly as much recoil energy as the famously difficult-to-tame British L1A1 SLR FAL derivative! While it’s not shown on the graph, the .264 caliber AR-12 also produces higher calculated recoil velocities (the speed at which the recoil is applied, which helps inform whether a rifle will produce more of a “push” or a sharp “kick”) than the L1A1, as well.

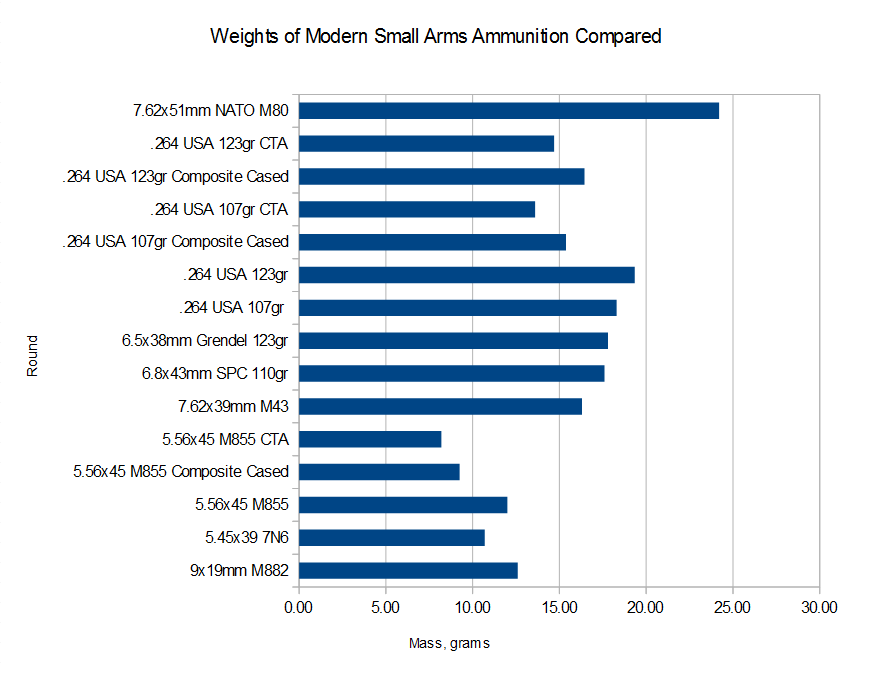

Weight is another concern when adopting a round so much larger than current intermediate calibers. We can see how the .264 USA compares to those same rounds, with composite plastic/brass-cased, and plastic-cased telescoped .264 and 5.56mm rounds thrown in. The 107gr .264 USA CTA cartridge does nearly achieve the same light weight as the existing brass-cased 5.56mm round (at 13.6 grams, versus 12 for 5.56mm), but still falls well short of the 8.2 gram weight of 5.56mm CTA. It is also interesting to note that the .264 USA appears to have been designed from the outset for the composite metallic-polymer cartridge case configuration, and that rounds of this type were requested in the initial solicitation. Such cartridges have been produced, although the extent to which they will be or already have been tested, as well as the current status of that project, is unknown to me.

EDIT 9/25/2016: Anthony Williams has just published measured weight figures for the .264 and .277 USA rounds:

Some weights I measured today (from single samples of each):

264 USA with brass case and 108 grain bullet: 19.58 g

264 USA with polymer/steel case and 108 grain bullet: 15.03 g

264 USA with brass case and 123 grain bullet: 20.43 g

264 USA with polymer/steel case and 123 grain bullet: 15.87 g

277 USA with brass case and 135 grain bullet: 21.17 g

277 USA with polymer/steel case and 135 grain bullet: 16.69 g

I cannot help but notice that the figure for the 123gr .264 USA load is virtually identical to a weight estimate for an 8-gram 6.5mm GPC that I published in 2013:

With the case and projectile finished, and the specified performance achieved, all that was left was to weigh the cartridge and calculate its recoil. The volume of the brass case was 1.109 cm^3, resulting in a weight of 9.43 g. The weight of the powder charge was 2.35 g (36.3 grains), and the bullet, of course, was 8 grams. To calculate the weight of a large rifle primer, I set five together on my powder scale, weighed them, and averaged the result, which was approximately .35 g. When summed, the 6.5×50/8/00 weighed 20.13 grams; more than two grams heavier than Mr. Williams’ initial estimate, and nearly 70% heavier than 5.56mm.

For those interested in more discussion on weight and how it affects the load of the infantry platoon, I have written several articles on the subject, which you can read at the links below:

The Case Against a General-Purpose Cartridge

The General Purpose Cartridge Revisited

An Analysis of the Soldier’s Load with 6.5mm Cased Telescoped Ammunition (Part 1)

An Analysis of the Soldier’s Load with 6.5mm Cased Telescoped Ammunition (Part 2)

I should also point out that the 6.5mm cased telescoped (CTA) round in Kori Phillips’ presentation for the newly rebadged CTSAS (formerly LSAT) program may be based on the .264 USA, although the performance figures shown in the document may indicate an even more powerful round. Regardless, I have chosen to create my own estimate for weight for a CTA variant of the .264 USA, used in the weight comparison above.

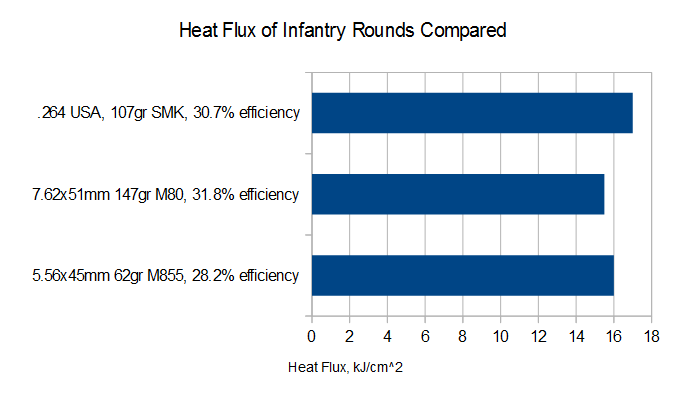

One final dimension that is worth looking at is heat flux, or more simply, how quickly a given round heats up a weapon’s barrel. Rounds with a higher heat flux will heat barrels more quickly, and those with a lower heat flux will do so more slowly. With that in mind, I have compared the heat flux of the 5.56x45mm, 7.62x51mm, and .264 USA rounds in the graph below (efficiency figures were calculated using a Powley computer):

To sum up, then, the .264 USA represents a double-edged sword for the infantryman. Higher performance than either the 5.56mm or 7.62mm, it could potentially allow troops (especially those with support weapons like machine guns or marksman’s rifles) to reach out and eliminate the enemy at longer distances than is practical with the current squad-level small arms suite. However, its increased recoil, weight, and heat flux versus 5.56mm present a very serious question about what tradeoffs should be made in the next iteration of US and NATO standard small arms ammunition. Should these disadvantages – potentially reducing the rate of fire and accuracy of the infantry’s weapons – be accepted in trade for longer effective range and greater lethality? Or should another compromise be struck, instead?

Your Privacy Choices

Your Privacy Choices