Previously, we discussed the benefits of and challenges facing saboted projectile ammunition, including the advantages of decoupling the diameters of the bore and the projectile, and the problems of accuracy during sabot discarding. One concept that could possibly provide many of the benefits of saboted projectile ammunition without the drawbacks is the idea of having a malleable projectile that is forced through a conical section of bore, squeezing it down to a smaller shape. This increases, to a degree, the swept volume of the barrel, while not requiring any discarding sabot and not producing “wasted” energy that goes into propelling the mass of the sabot out of the barrel.

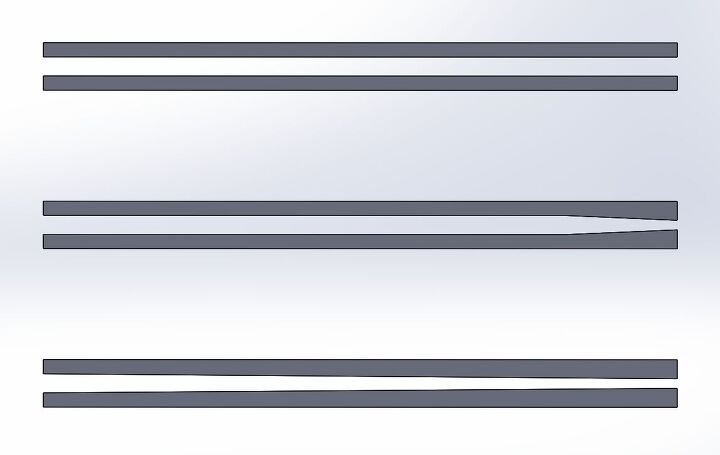

Three bore contours. Top is a conventional bore profile with no taper. Bottom is a fully tapered bore that gradually decreases over its whole length. Middle is a bore with taper only at the end, as with an attachment.

Squeezebore barrels require a tapered section, but this can be anywhere in the barrel so long as it is stiff enough and gradual enough to squeeze the projectile down without quickly wearing out. The best location for both barrel life and swept volume is therefore at the end of the barrel, which can be accomplished via a barrel attachment. This affords interesting opportunities for squeezebore barrels, as a rifle could come equipped with a squeezebore attachment for firing supersonic projectiles, which could then be swapped out for a full-diameter suppressor attachment for firing full-caliber subsonic projectiles, if necessary.

A WWII-era British Mk. VII Tetrarch tank with a “Littlejohn” squeezebore adaptor for its 2 pounder (40mm) gun. This attachment had to be used with special squeezebore ammunition, but gave the guns equipped with it considerably higher muzzle velocity and penetrating power when used so. Image source: wikimedia.org

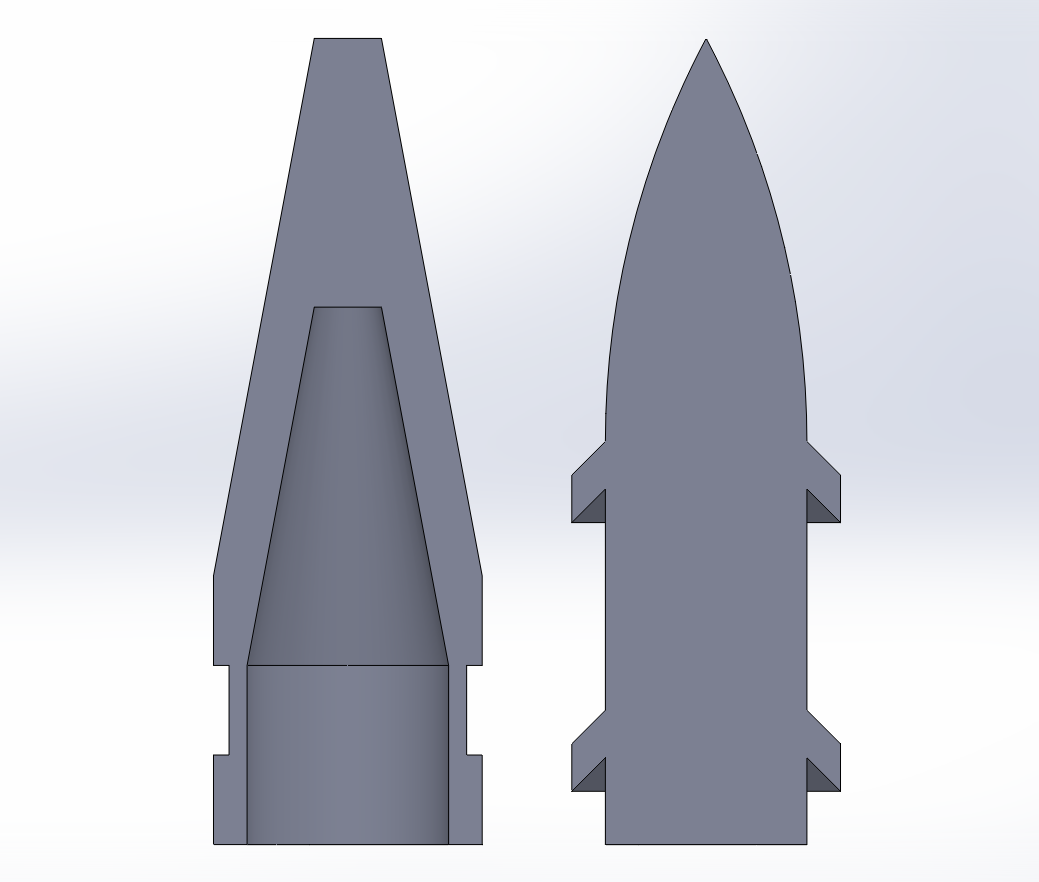

Cross sections of two different designs of squeezebore bullets. On the left is a hollow conical design, which could potentially be stacked in a SALVO arrangement, while on the right is a flanged design, similar to that of armor piercing squeezebore projectiles used in World War II.

The additional swept volume coupled with lightweight projectiles allows muzzle velocities close to that possible with sabot-firing designs, but the squeezebore concept (also called the “Gerlich principle”) does have some limitations. At least historically, squeezebore barrels do not last very long relative to conventional barrels (whereas the sabots typically reduce barrel wear), something that is partially alleviated by making the squeezing portion of the barrel a removable attachment. Also, squeezebore projectiles may be difficult to make, and a squeezebore weapon may limit the kinds of projectiles which can be fired through such a barrel, and there may be less dimensional control over the fired projectile’s shape once it has been squeezed down. Finally, there is a limit to how much a projectile can be squeezed down by a barrel; the few large-caliber squeezebore artillery guns that have been made have typically stayed at a ratio of about 0.70-0.75 for the final diameter versus the initial diameter.

Still, the squeezebore concept offers less technically challenging way to gain much the same advantage as a sabot-firing weapon, despite its disadvantages.

Your Privacy Choices

Your Privacy Choices