What happens when you take the two concepts of a traditional, full-power rifle and machine gun round, and a small-caliber, high-velocity round, and smash them together? You get one of the most extreme military small arms calibers ever developed, and one of the last small arms projects from the twilight of the Soviet Union.

The 6x49mm seems nuts until you see its competition: That’s the 10x54mmR heavy flechette round that was also designed for the Unified project, on the right. Note the groove in the body of the case on the 6mm – this was designed to help the steel case expand without failing, a critical design feature in a round as high pressure as this one. Image owned by Maxim Popenker, used with permission.

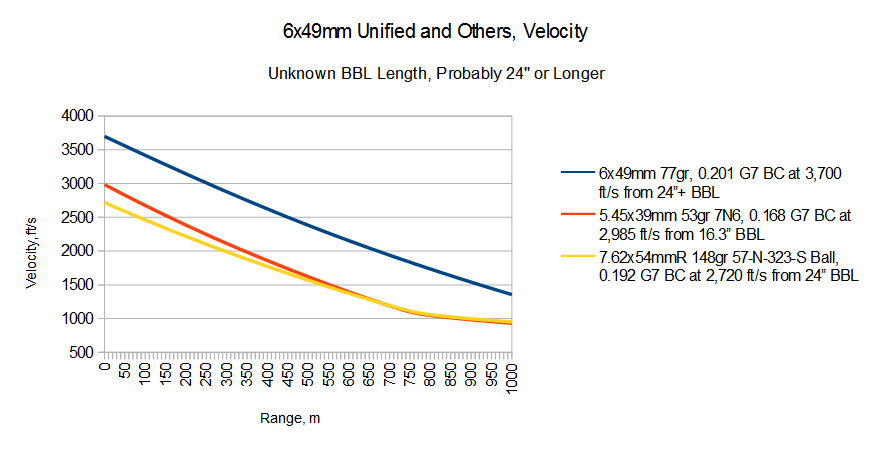

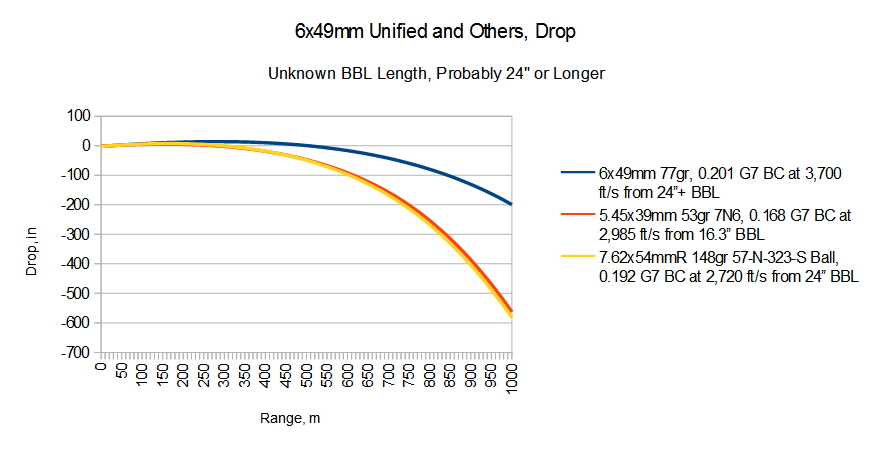

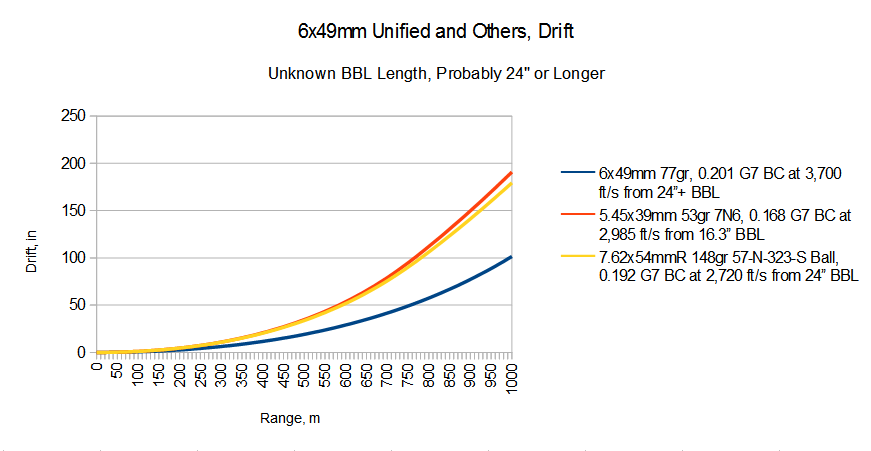

The 6x49mm Unified was not your average full-power military round. It’s a 6mm, or .243 caliber round – considerably smaller than almost every other round in its class. It fired a light bullet, just five grams (77gr), and had an incredibly high muzzle velocity of close to 1,150 m/s – that’s over 3,700 ft/s to the yanks reading this. These figures are much more characteristic of intermediate small-caliber, high-velocity rifle rounds, but the 6x49mm was no intermediate cartridge, as it produced muzzle energies of close to 3,200 J. Because of its high velocity, though, it was incredibly flat-shooting, and reportedly accurate to 1,500m. This claim seems extreme, but consider that the 6x49mm Unified boasts a supersonic range of 1,150m, a full 50% longer than normal .30 caliber full-power rounds!

Enough talk, on to the graphs:

In addition to its amazing external ballistics, the 6mm Unified was also far lighter than the round it was designed to replace, the venerable 7.62x54mmR. Compared to the 25.5 grams of the 7.62mm, the 6mm Unified weighed in at below 16 grams, nearly a 40% reduction in weight!

Ultimately, the fall of Communism and the dissolution of the Soviet Union ended development of the 6x49mm Unified round and the machine gun and marksman’s rifle that were designed to fire it. Also, because of its heavy propellant charge relative to its small 6mm bore, the round produced incredible barrel wear to go along with its incredible ballistics. In machine guns, the zippy 6mm wore out barrels after just 5,000-6,000 rounds, about a third of the life span that could be expected from a 7.62mm barrel.

The 6mm Unified (center) alongside the 5.45x39mm (top) and 7.62x54mmR (bottom), the latter of which it was designed to replace. Image owned by Maxim Popenker, used with permission.

However, there are rumors that the 6mm Unified is not yet dead, but merely sleeping. Will the Russians resurrect development of this ballistic wonder? Could improved barrel metallurgy finally make scorpion-pepper-hot rounds like this a reality? Who knows, but it’s fun to speculate!

Your Privacy Choices

Your Privacy Choices