One quiet day back In 1993, Ron Allen, who was making semiconductor parts for soon-to-be Silicon Valley powerhouses, received a strange telephone call: a man on the line wanted Allen Engineering to build and design rifle silencers. “At the time, I thought it was some sort of sting operation,” said Allen. On the phone was Phil Seberger who ran a garage and basement suppressor business in Shingleton, California. Seberger needed someone with a true machinist’s skill to make parts like muzzle brakes for his company: Ops Inc.

“Phil was a genius and an amazing electrical engineer,” said Allen. “But some of his self-taught machining techniques would make me cringe.” In the late 1970’s and early 1980’s, in the process of designing suppressors, Seberger devised a new technique to precisely measure and record sound waves of a suppressed rifle. Using sensitive microphones and an oscilloscope, he visualized the higher wave length sounds of different baffle designs in his Ops Inc prototypes.

Ops Inc/Allen Engineering. Credit DangerDan – AR15.com

However, the simple task of capturing a screen shot of the oscilloscope output that we would take for granted in today’s high-tech world did not exist in the early days of Seberger’s research and design phases. So he used his electrical engineering skills along with his experience as a photographer in the military to develop a process to take polaroid photographs of the oscilloscope screen at the exact moment the rifle was fired. “It was that technique that allowed him to really refine Ops Inc baffle designs,” said Allen.

Seberger’s innovative testing processes quickly caught the attention of U.S. Army engineers in Aberdeen, Maryland. “They were amazed that he was able to accurately replicate test results in his basement shop against those at the Aberdeen laboratories,” said Allen. With that, Ops Inc’s military and government sales were off and running.

Ops Inc/Allen Engineering. Credit GreenGoose – AR15.com

But, like most geniuses and revolutionaries, Seberger was an eccentric personality. “He could be a difficult person to do business with,” said Allen. In the early days of the Ops Inc and Allen Engineering partnership, Seberger would regularly find other companies who would manufacture parts slightly cheaper than Allen. But after a few months, these companies would usually tire of dealing with Seberger’s behavior and drop the Ops Inc projects all together, leaving him to return to Allen Engineering time and time again.

Ops Inc/Allen Engineering. Credit: plante72 – AR15.com

In the beginning, Allen was helping manufacture the Ops Inc 3rd model for small military contracts in very limited quantities. “Ops Inc couldn’t have produced more than a few hundred silencers before Phil brought me on to help,” said Allen. He believes that the Ops Inc serial numbers must have started at the 1000 mark and can only remember the lowest serial number he’s ever personally seen being around 1050. “Phil’s basement shop was not setup for any sort of volume,” said Allen.

But everything changed with the development of the Mark 12 Special Purpose Rifle (MK12 SPR) by the U.S. Military in the early 2000’s. The custom-designed upper receiver groups were built around the Ops Inc 12th model – an over-the-barrel (OTB) design that requires a specific barrel profile, barrel collar and brake mount. The platform was intended to be nearly silent when measured 50-100 yards away from the shooter, reducing the report by more than 40 decibels (clarification: this was the original reduction value used by Seberger in the beginning).

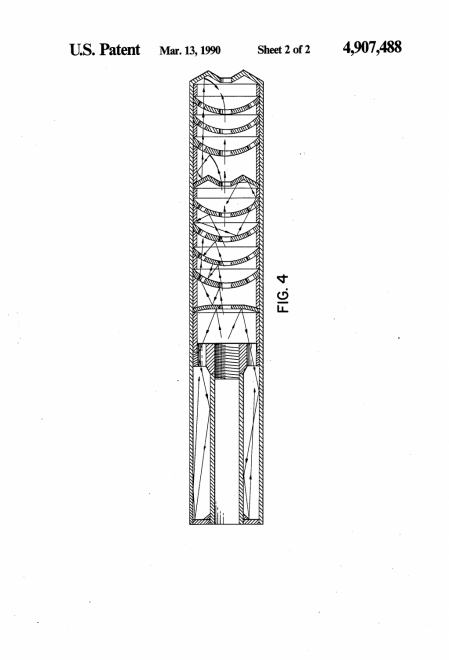

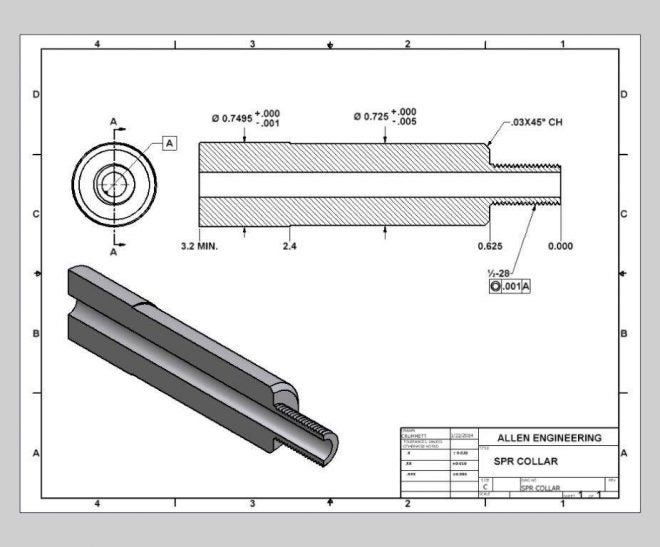

Ops Inc Patent

Ops Inc Patent

Ops Inc/Allen Engineering. Credit: m1garand30064 on an Accurate Ordnance platform

The first approximately 100 Ops Inc 12th Models were built by RD Systems in South Beloit, Illinois. But, as it happened so many times in the past, Seberger’s unique personality and budget-minded ways strained Ops Inc’s business plans. As orders rolled in, RD Systems refused to release the first batch of 12th Models to Ops Inc on the grounds of ‘failure to pay’. Eventually, that initial run was released, but the business relationship with RD Systems was over.

That first batch of Ops Inc 12th Models, to Allen’s knowledge, were the only ones not directly produced by Allen Engineering. From that point forward, Allen worked side-by-side with Seberger to help manufacture one of the most successful rifle/suppressor combinations in military history. Whether or not you own a silencer marked as Ops Inc or Allen Engineering, chances are that it was made by Allen himself.

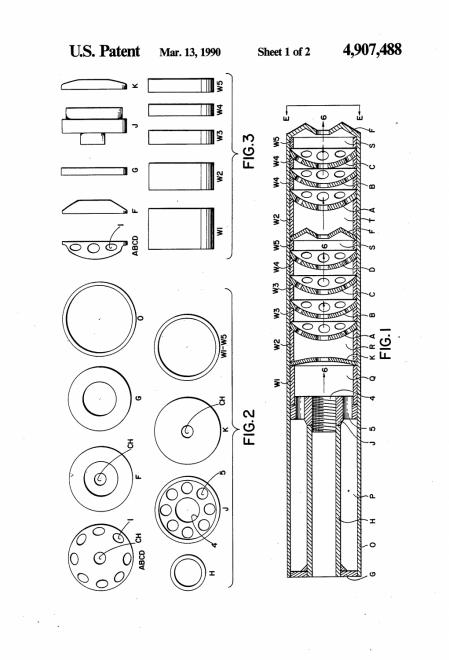

Ops Inc/Allen Engineering. Barrel profile specifications.

Allen Engineering. Brake mount and barrel collar.

Ops Inc/Allen Engineering. Credit: RTUtah – AR15.com. (Length comparison with a mounted AAC suppressor)

But the civilian market was a different story all together. “Phil didn’t want anything to do with civilian sales,” said Allen. “Even with parts as simple as muzzle brakes.” It was around this time when Allen and Steve Thompson from ADCO Firearms realized that silencer sales to the civilian market was the future of the industry. Thompson, who was close friends with the subcontractors of the original MK12 upper for the Naval Surface Warfare Center (NSWC) in Crane, Indiana, slowly convinced Seberger to allow ADCO to sell Ops Inc products on a limited basis. Even so, at one point Seberger actually threatened to kill Thompson for selling brakes that he had bought from a third party. In spite of the threats and personality fluctuations, somehow the trio were able to move civilian sales forward.

Ops Inc/Allen Engineering. Credit: plante72 – AR15.com

As MK12 use increased on the battlefields of Iraq and Afghanistan, the military’s demand for 12th models increased proportionally. Allen stepped up production while also refining his manufacturing processes along the way.

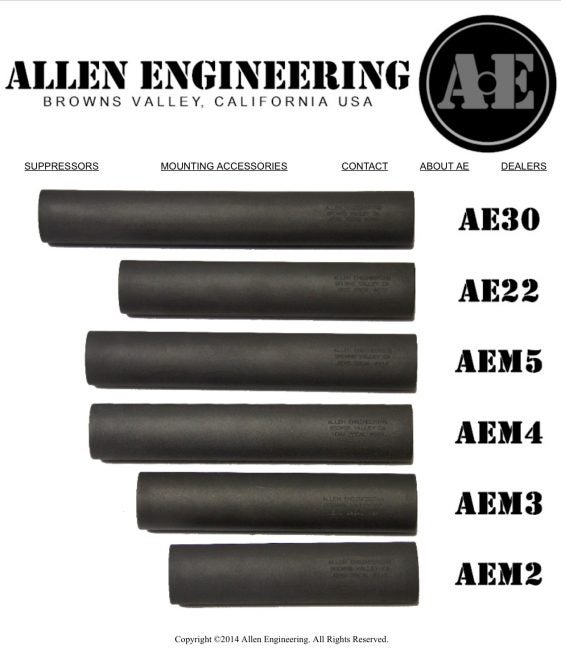

Allen Engineering. Models

For a variety of reasons, Seberger had always intended for Allen to take over the Ops Inc business at some point in the future. But after a major stroke in 2010, everything changed – including Seberger’s will. When he passed away later that year, Seberger’s daughter inherited Ops Inc in it’s entirety. The rest of the details between Allen and the new Ops Inc ownership are private. But, it’s safe to say that Allen Engineering didn’t take over Ops Inc or receive any financial gain from Seberger’s estate. In fact, without getting in too deep, Allen suffered significant financial losses as a result of his dealings with the new Ops Inc management.

In 2013, Ops Inc’s FFL/SOT was revoked for alleged record keeping and export fee violations surrounding a deal for an order of suppressors to the Canadian Military. Thankfully, Allen Engineering kept their FFL and their independent suppressor business and continued to produce all of the current Ops Inc designs as “AE” models. “Besides a few less baffle holes, the designs are exactly the same as the Ops Inc models,” said Allen.

Ops Inc/Allen Engineering. Credit: BurtSaun1049 – AR15.com

Allen couldn’t be more modest or easy going if he tried. Where he would be well within his rights to show hate or spite towards certain individuals who have treated both him and his business poorly, Allen just refers to them as “difficult personalities”. All the while he continues to manufacture silencers and, by all accounts, provide some of the best customer service in the industry. Allen could sell barrel/mount/suppressor combinations as a package directly from Allen Engineering, but he respects his relationships with ADCO and other retailers too much to even think about encroaching on their business.

Can you identify the Ops Inc silencers?

After nearly 30 years of development, the Ops Inc designs that now live on as Allen Engineering models are still relevant, even in a market flooded with advanced materials and quick detach mounting options. And if you’ve ever had the pleasure of shooting a MK12 you can see why – it’s arguably the quietest 5.56mm semiautomatic setup in existence.

Besides the AEM5 (Ops Inc 12th Model equivalent), Allen Engineering offers other lengths, calibers and mounting options that are solid performers on a variety of different platforms. Retailers like ADCO, Hansohn Brothers, DSG Arms, Capitol Armory as well as others sell current AE silencer models.

I don’t make a lot of suppressors, but every one gets inspected, and finish machined by me personally. That’s why I warranty them for life.

As for the future, Allen is designing a 300BLK suppressor but isn’t ready to commit to a timeline. “The baffle design has to be optimized for the larger subsonic rounds,” said Allen.

So, why isn’t this story entitled Ops Inc instead of Allen Engineering? For one, as a suppressor company, Ops Inc is now basically defunct. Second, Allen has produced the lions share of the MK12 suppressors, whether or not they were marked Ops Inc as the manufacturer.

And finally, Ron Allen is the real hero (my words, not his): Whereas Seberger’s designs and testing techniques were ground breaking, without Allen as well as Thompson from ADCO, the civilian market would have never had the chance to experience highly regarded OTB silencers like the AEM5.

Thank you Ron.

Form 5, brakes/mounts/collars sales to:

Allen Engineering – http://aesuppressors.com/

11250 Peoria Rd, Browns Valley, CA. 95918-9654

530-742-3248

mbsman@sbcglobal.net

Form 3 sales to:

Allen Engineering – http://aesuppressors.com/

1201 Industrial Way

Sparks NV 89431

* Allen Enginering does not offer any business hours open to the public.

ADCO Firearms, LLC – https://www.adcofirearms.com/

6481 Monroe St.

Sylvania, OH 43560

Fax 419.882.6627

Phone 419.882.8079

Thanks to BurtSaun1049 and the rest of my friends at AR15.com for keeping this Ops Inc/Allen Engineering discussion thread going. If you are looking for additional details and pictures, stop by and have a good, long read.

Your Privacy Choices

Your Privacy Choices