Don’t look at me like that. Yes, it’s perfectly legal to build your own suppressor. Following the same process as you would to make a registered and legal short barreled rifle (SBR) or short barreled shotgun (SBS), you can build a device that will make your favorite gun quieter, have some fun and even learn a few things along the way. Still with me? Great. Let’s get started.

ALERT: New Series For 2020 – Build Your Own Form 1 Suppressor

https://www.thefirearmblog.com/blog/2020/04/18/form-1-suppressor/

Part 1:

- Introduction

- Maker vs Manufacturer

- Disclaimers

- Legal Requirements

- Basics

- Materials

- Basic Tools

- Homework

Part 2: (IN PROCESS/DELAYED FOR LEGALITY CONCERNS)

- Types/Designs

- Calibers

- ATF Form 5320.1 (Form 1)

- Paper vs EFile

- Resources

- Part Suppliers

- While You Wait

- Homework

Part 3:

- Approval

- Building/Machining

- Working With Metal

- Bore Diameter and Concentricity

- Baffle Clipping/Mouse Holes

- Mounting/Testing

- Coating/Painting

- Final Thoughts

1.1 Build Your Own – Introduction

Commercial suppressor manufacturers have been conjuring up some awesome products in the last few years. Modern designs, materials and manufacturing processes have given buyers enough market variety to suppress almost any gun in their safe.

So why would you want to build your own silencer? For the most part, homemade suppressors can be made for a fraction of the cost of their commercial cousins. For example, my combination titanium, steel and aluminum 9mm suppressor cost about $150 (not including a booster). And my full titanium 5.56mm build cost about $350.

In addition, you can use your choice of materials, specific dimensions and custom designs to build a can that matches your needs precisely. It’s also just good clean fun: by building your owner suppressor you get a better understanding behind the engineering that goes into the products made by the big companies. Suppressing firearms is both a science and an art. Ok, it’s mostly science.

If you are not a suppressor owner yet, I highly suggest that your first (and probably second) purchase come from a commercial manufacturer rather than attempting to make one on your own. Even if you are an expert machinist, I believe your first venture into the world of silencers should be store bought. Why? Because if something doesn’t turn out right – it’s loud, or it doesn’t thread on properly, or it’s super heavy – you risk being soured on suppressors forever. And nobody wants that. In addition, commercial offerings are backed by a warranty; if something is out of spec, just send it to back and get it fixed.

Hopefully you had the chance to read through the ‘Beginner’s Guide to Suppressors’ series here at TFB. If not, I suggest that you at least read through Part 1 that covers some basic information including the National Firearms Act (NFA) legality in your area, suppressor terminology and host (gun) basics. Most of that starter information will not be repeated here in the ‘build your own’ series.

Titanium parts.

1.2 Build Your Own – Maker vs Manufacturer

As an individual or entity (Trust or LLC) suppressor builder (also known as ‘Form 1’ builders), you are known as a ‘Maker’. While on the other hand, the Bureau of Alcohol Tobacco and Firearms (BATFE) classifies Federal Firearms Licensee/Special Occupational Tax holders (FFL/SOTs) as ‘Manufacturers’. Whereas manufacturers are in business to design, build, test and sell NFA items like suppressors, makers are approved to build suppressors for non-commercial (or resale) use only.

What this means for you:

- As a maker, you are not allowed to build a suppressor for sale. That doesn’t mean that you can’t sell a suppressor you build down the road (you won’t), but the intent is that you are building one just for personal (or entity) use only.

- Manufacturers are allowed to apply for BATFE variances to certain rules and regulations in the design and build process. For example, a suppressor company can petition the BATFE for a variance for a design that pushes the legal limits that define silencers – extra parts, modularity, etc. Makers, on the other hand, must follow all BATFE rules and regulations as written.

- As a maker, you cannot ‘test’ or ‘prototype’ your designs like a manufacturer may be allowed to do. Your approved BATFE Form 5320.1 “Form 1” allows you to build one suppressor as described. More on this topic later in the series.

- Manufacturers are allowed to repair damaged or worn suppressors with certain restrictions. Makers are not allowed to repair suppressors, even one’s they built themselves. There is some debate on this front, but we will tackle that discussion in Part 3.

A freshly drilled titanium baffle I made for a 5.56mm Form 1 suppressor.

1.3 Build Your Own Silencer – Disclaimers

I know we are all responsible, levelheaded and lawful firearm owners, but since we will be venturing into the highly niche area of building a suppressor lawfully, here are a few words of caution:

- I am not a machinist, master craftsman, CNC operator or blacksmith. This guide is meant for the amateur hobbyist with a basic knowledge of tools and metalworking. Know your skills and limitations in the shop.

- I am not an attorney. And this guide isn’t meant to be legal advice. When in doubt, do your own research and contact the BATFE for clarification.

- You are responsible for following all safety precautions. This applies to when you handle firearms as well as the tools in your garage. And don’t forget the ear and eye protection.

1.4 Build Your Own Silencer – Legal Requirements

As discussed in the Beginner’s Guide, check the local, state and federal laws before starting down the path towards a homemade suppressor.

We mentioned the BATFE Form 1 above, and we are going to go into more detail in this part as well as the following parts. To put it simply: You need an approved Form 1 before you can start building your suppressor. Do not attempt to machine parts, drill holes or otherwise do anything that would be construed as building an unregistered suppressor.

That being said, you can purchase the parts necessary to build you silencer while you wait for your Form 1 to be approved. After all, the majority of these parts are commercially available at metal supply sources, auto parts stores, hardware stores or directly from a machine shop.

The key here is intent and common sense. Buying metal tubes is one thing; forming baffle cones and drilling bore holes is something completely different. For the most part, if your parts can be threaded onto a barrel and can suppress the sound of a fired shot, it’s a silencer and needs an approved Form 1. When in doubt, wait for your Form 1 to come back approved from the BATFE.

For your own good, and the betterment of shooters, collectors, hobbyists and builders everywhere, do not attempt to push the boundaries of the law, no matter how slight.

I am not trying to make anyone nervous, but a healthy amount of caution is ok when building NFA regulated items.

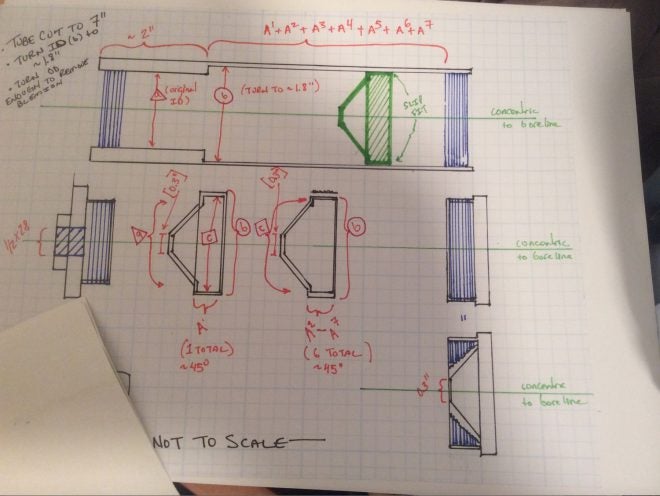

On the plus side, you don’t need to have your entire build planned out prior to filing your Form 1. Besides your individual or entity information, the BATFE only needs the caliber of your silencer and it’s overall length. A basic design or sketch is not required, but could help keep your form out of “Pending Research” – a period of time after the submission of your Form 1 where the BATFE reviews the details of your proposed build and decides whether or not they need further information prior to processing and approval.

Don’t worry, we are going to guide you the entire Form 1 process in Part 2.

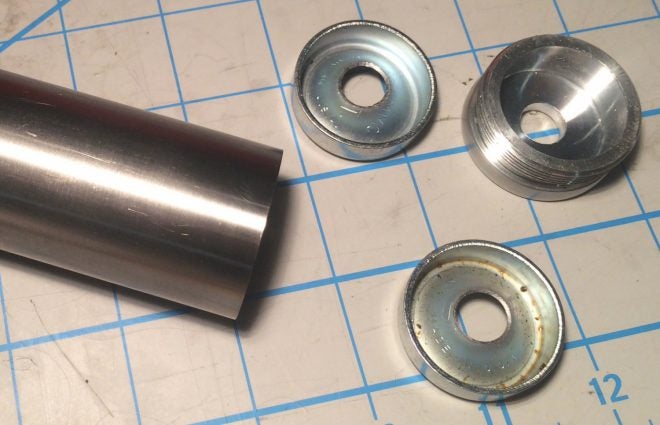

Before: My 1.5″ titanium tube with baffles formed from steel freeze plugs and an aluminum end cap. This is a short freeze plug build for a 9mm pistol.

After: My 1.5″ titanium tube with baffles formed from steel freeze plugs and an aluminum end cap. This is a short freeze plug build for a 9mm pistol.

1.5 Build Your Own Silencer – Basics

Similar to when buying a commercial suppressor, throughout the build process it is very important to keep your needs, wants and expectations in mind. Be realistic with your goals and your budget. Here are a few things to watch out for:

- Costs: Especially when it comes to rimfire projects, it is easy to get close to the price of a well-built commercial can.

- Weight: There can be a tendency to overbuild your suppressor out of an abundance of caution. Just keep in mind that all those materials on the end of your barrel will add up fast.

- Length: Similar to weight, many builders can attempt to make a silencer too long in the hopes of a further reduction in noise. Stick to ‘normal’ sizes and lengths this time.

- Baffles/Monocore: There will be a temptation to get creative with your silencer’s internals. Remember, since you are a maker and not a manufacturer, you are not allowed to prototype and test different designs along the way. For your first build, stay with a proven, easy to make design.

1.6 Materials

Titanium scrap I picked up from eBay. After approval all of this turns into a 7″ x 2″ OD direct-thread 5.56 suppressor.

Here’s where we start getting down to business – picking out the materials you need to start your build. But before we get down to actual parts and suppliers, lets talk about the metals that can be used to build suppressors.

- Aluminum: A lightweight metal that is easy to machine, aluminum is typically only used on rimfire builds or some pistol builds with caution.

- Stainless Steel: Strong but heavy, stainless steel can be used on almost any type of host. Because of the weight limitations, stainless steel builds on the end of long rifle barrels should be avoided.

- Titanium: Similar in weight to aluminum but with comparable strength to steel, titanium is an excellent choice for suppressor building. The downsides here are cost (about five times the cost of comparable steel) and machinability – low drilling speeds, cutting oil and temperature management.

- Carbon fiber and plastics builds are (somewhat) possible but should be considered advanced builds and outside the bounds of this guide.

It is important to note that these materials can be used in combination with each other. For example, for a pistol suppressor you could use a titanium tube with steel or stainless steel baffles.

Proper planning is key. You don’t have to be a mechanical engineer, but simple sketches go a long way.

Writers Note: Ok, here’s something I neglected to mention in the beginner’s guide. The tube (where the manufacturer/makers engraving is usually located) of the silencer is considered to be irreplaceable. Meaning that in the highly unlikely event of a catastrophic failure, the tube cannot be replaced, even by a licensed manufacturer. The tube can be shortened to affect a repair, but it cannot be lengthened or completely replaced (without paying another $200 transfer tax and waiting for a Form 4 to get approved).

Knowing this fact, as a maker, my suggestion is to use the best material, proper thickness and machining possible. This build needs to last a lifetime (or more). However, if damaged, end-caps, adapters and internals can all be replaced by a licensed manufacturer. All without having to pay another $200.

In fact, keep this in the back of your mind: If you somehow manage to make the worst silencer ever produced (it actually makes your gun louder) you can send it off to one of a few different manufacturers who will re-core (gut and replace) your silencers baffles and caps without having to pay another $200 tax and wait six months for approval.

1.7 Basic Tools

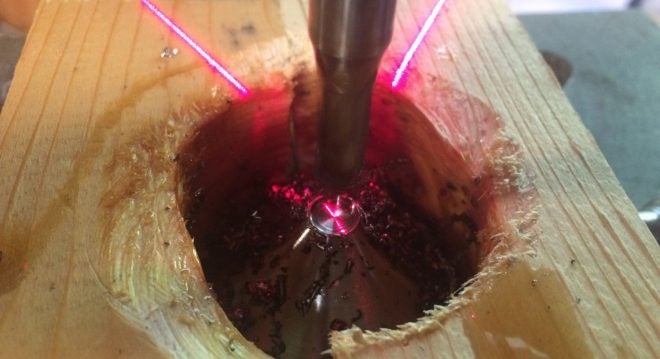

An end mill I picked up from Amazon for about $20. Regular drill bits will work, but an end mill will last longer, especially when cutting titanium.

I am not going to suggest that anyone needs to run out and buy a lathe or that you need to have a garage full of the best tools money can buy. However, you do need some basic equipment to build your own suppressor.

- Drill: A good rechargeable or plugin drill is a must. A drill press is better.

- Drill bits: Get a new set of bits that are suitable for metalwork.

- Hacksaw: For trimming spacer material. A Dremel will also work

- Files: Round, flat and triangular for clipping baffles and evening out spacers. Grinders and a belt sander are nice to have.

- Heavy duty vice: I’ll be honest, if you are forming your own baffle cones, a hydraulic shop press really is preferred. But with the right shop vice, it can be done. Plans for building your own press out of 2×4’s and using the hydraulic jack from your car can be found here.

- Sandpaper: Smoothing and polishing.

- Cutting oil: For drilling an cutting titanium.

I’m drilling a bore in a titanium baffle using an end mill and dark cutting oil.

1.8 Build Your Own Silencer- Homework

We are going to start the next part off by talking about silencer design basics, caliber ratings and submitting your BATFE Form 1.

First, decide the host that your project will eventually live on and make sure it’s suitable to be suppressed.

Second, take some time to do a little research on your own. Googling ‘suppressor baffles’ will give you thousands of pictures to look through.

Hint: For your first build, you’ll be buying a pre-made tube, a threaded barrel adapter, end cap and baffle materials like freeze plugs or Valve Stem Retainers (VSR).

Lastly, download and familiarize yourself with the information needed for the BATFE Form 1. We’ll be filling that out in Part 2.

Glossary:

- Baffle – The cone-like sections inside the suppressor that work to slow and cool gasses.

- Baffle Stack – All of a suppressor’s baffles together acting as one sound-reducing system.

- Baffle Strike – When a bullet damages a silencer’s baffle.

- Blowback – Gases that would have normally exited the muzzle are redirect back through the barrel towards the shooter.

- Booster or Nielsen Device – An inertia device that uses the force of the trapped gases in the silencer to cycle the action of a semiautomatic pistol.

- Bore Hole – The hole in the baffles and end cap where the bullet passes through.

- Clipping – Openings encompassing part of the bore hole in baffles to aid in the creation of turbulence and increasing suppression. (also see ‘mouse holes’)

- Concentric – The process of ensuring that the entire suppressor is centered around the boreline of the barrel and barrel threading.

- Direct Thread – A type of suppressor that mounts directly on to a barrel without the need for a mount or adapter.

- End Cap – The muzzle end of the silencer.

- End Cap Strike – When a bullet damages a silencer’s end cap.

- Engraving – The maker, model number, maker location, caliber and serial number engraved on the main part of a suppressor as required by law.

- Form 1 – BATFE Form 5320.1 an Application to Make and Register a Firearm. An approved Form 1 is required to build a suppressor.

- Freeze Plug: Normally found in auto parts stores, theses inexpensive steel cups are made to be used in car engine blocks. They also can be drilled an pressed into Form 1 suppressor baffles.

- Inner Diameter (ID) – The inner diameter of a suppressor tube.

- Markings –The maker, model number, maker location, caliber and serial number engraved on the main part of a suppressor as required by law. (see engraving)

- Monocore – A type of one-piece baffle structure found inside some types of suppressors.

- Mount – The part of the suppressor that attached to the barrel of your gun.

- Mouse Holes – Semi-Circle holes encompassing part of the bore hole in baffles to aid in the creation of turbulence and increasing suppression. (also see ‘clipping’)

- Outer Diameter (OD) – The outer diameter of a suppressor tube.

- Over-The-Barrel – A type of silencer that uses proprietary mounts that starts before the muzzle of the barrel to increase a silencer’s volume.

- Spacer – The a section of metal that slips into your tube to create space between baffles.

- Thread pitch – A variety of different thread patterns on the muzzle of a barrel that are usually specific to a caliber.

- Tube – The body of the silencer.

- Valve Stem Retainers (VSR) – Made of steel or titanium these stepped-cones are made to retain valve stems in car engines. They also make great baffles in Form 1 suppressors.

- Volume – The amount of space inside a silencer that is available for gases to be trapped, slowed and cooled.

My Form 1 “Tank” eats my commercial can (SilencerCo Saker762).

See you for Part 2 of ‘Build Your Own Silencer’.

Your Privacy Choices

Your Privacy Choices